Clerestory frame

A technology of air building and frame, applied in the field of air building, can solve the problems of poor wind and snow resistance, rainwater leakage at the overlapping joints of color plates, and low overall rigidity, and achieve strong wind and snow resistance, ventilation and lighting Good effect, good effect of leak-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

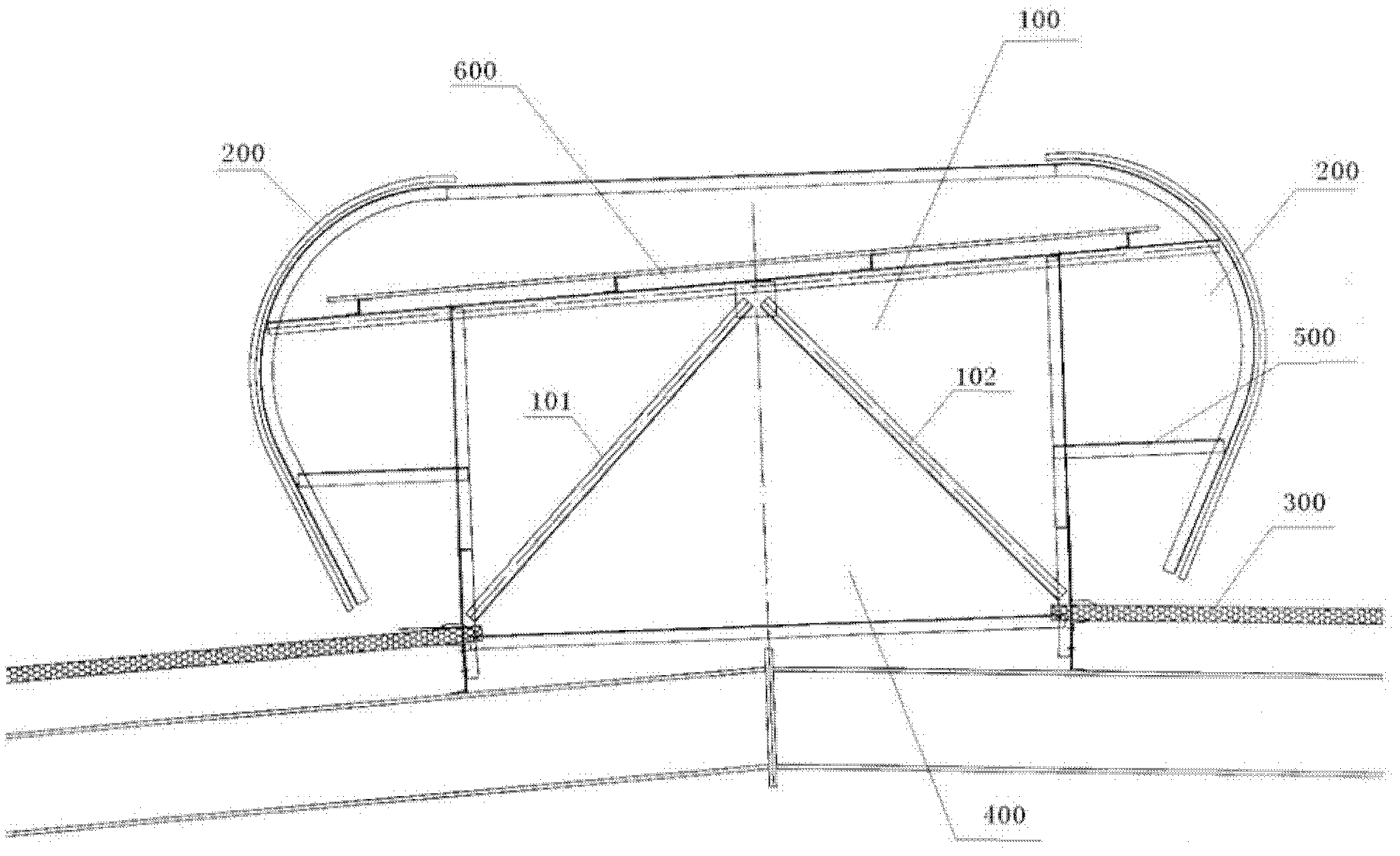

[0010] figure 1 is a structural schematic diagram of the present invention, such as figure 1 As shown, the present invention includes a main framework 100 and two arc-shaped sub-frames 200, the main framework 100 and the arc-shaped sub-frame 200 are installed on the roof 300, and the main framework 100 includes a left slanting beam bar 101 and a right slanting beam rod 102 and connecting rod 103, the connecting rod 103 is inclined relative to the roof 300, the bottom of the main frame 100 forms the throat 400 through the left slanting beam rod 101 and the right slanting beam rod 102, the two connecting rods 103 on the main frame 100 The end is connected with the arc-shaped sub-frame 200 , and an auxiliary fixing rod 500 is arranged between the arc-shaped sub-frame 200 and the main frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com