Self-adhesive waterproof roll material for color steel roofs of buildings and method for manufacturing self-adhesive waterproof roll material

A self-adhesive waterproof coiled material, self-adhesive waterproof technology, applied in the direction of chemical instruments and methods, hydraulic material layered products, layered products, etc., can solve color steel roof leakage, gap deformation, color steel deformation, etc. problem, to achieve the effect of lowering the roof temperature, strong adhesion, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

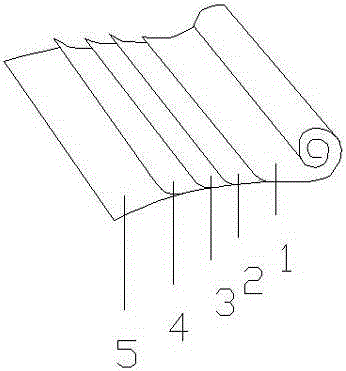

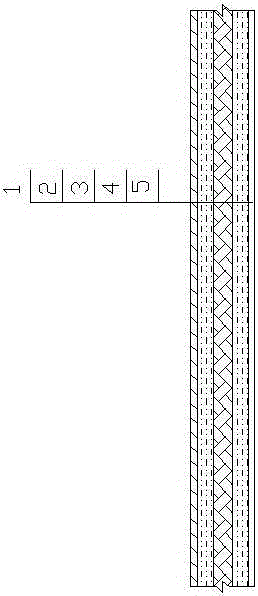

[0019] Preparation process of the present invention

[0020] 1. Preparation of self-adhesive waterproof layer

[0021] The self-adhesive waterproof layer is mainly a modified asphalt mixture made of the following raw materials in parts by weight: 50-60 parts of asphalt, 2-10 parts of base oil, 0.5-2.5 parts of resin, and 8-15 parts of recycled butyl rubber powder , 15-25 parts of heavy calcium powder.

[0022] The asphalt in the modified asphalt mixture of the self-adhesive waterproof layer of the present invention is road petroleum asphalt, the resin is KT resin containing grafted maleic anhydride, and the regenerated butyl rubber powder refers to 40-60 mesh regenerated butyl rubber powder; The fabric reinforcing layer is composite felt of polyester felt and glass fiber grid cloth.

[0023] The present invention manufactures the modified asphalt mixture for the self-adhesive waterproof coiled material self-adhesive waterproof layer of the building color steel roof, and the ...

Embodiment 1

[0026] Add 5500 kg of asphalt and 600 kg of base oil into the reaction kettle, heat up and stir for dehydration, add 100 kg of resin when it reaches 160±5°C, and stir for 90 minutes at 160±5°C to dissolve the KT resin evenly, and heat up at Add 1,100 kg of regenerated butyl rubber powder at a temperature of 200±10°C, and stir for 120 minutes at a temperature of 200±10°C to dissolve the regenerated butyl rubber powder evenly. Finally, add 2,000 kg of heavy calcium powder and stir for 120 minutes. Evenly, cool down to 160-180°C to prepare modified asphalt mixture for later use.

Embodiment 2

[0028] Add 5000 kg of asphalt and 200 kg of base oil into the reaction kettle, heat up and stir for dehydration, add 50 kg of resin when it reaches 160±5°C, and stir for 90 minutes at 160±5°C to dissolve the KT resin evenly, and heat up at Add 800 kg of regenerated butyl rubber powder at a temperature of 200±10°C and stir for 120 minutes at a temperature of 200±10°C to dissolve the regenerated butyl rubber powder evenly, and finally add 1,500 kg of heavy calcium powder and stir for 120 minutes. Evenly, cool down to 160-180°C to prepare modified asphalt mixture for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com