High-pressure plunger pump with automatic oil distributing system

A high-pressure plunger pump and oil system technology, which is applied to the components, pump components, mechanical equipment and other directions of the pumping device for elastic fluids, to achieve the effect of reducing the height of the pump body, good sealing performance, and simple structure improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

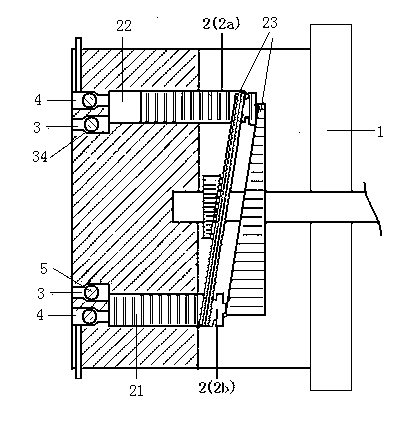

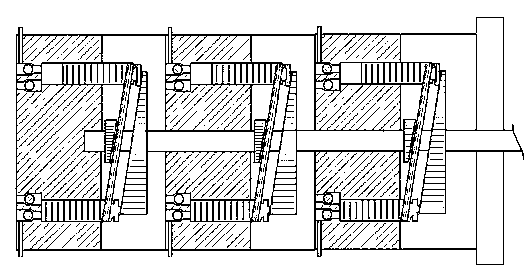

[0018] Such as figure 1 as shown,

[0019] The power equipment and component oil tank of the pump body of the present invention are not shown in the figure, and only a pair of plunger valves with opposite orientations among the plurality of plunger valves arranged in the pump body 1 are shown. Each plunger valve 2 (including A plunger valve 2 a and B plunger valve 2 b in the figure) is mainly composed of a valve stem 21 and a valve cylinder 22 , and a double swash plate 23 is arranged on the valve stem. Its self-distributing oil circuit system is that the bottom of the valve cylinder is equipped with an oil inlet 3 and an oil outlet 4, and the oil inlet and the oil outlet are respectively provided with a large diameter end and a small diameter end; the large diameter of the oil inlet The end communicates with the valve cylinder 22, and the small diameter end of the oil outlet communicates with the valve cylinder 22; a variable diameter slope 34 is provided between the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com