Optical proximity correction method, connection hole manufacturing method

A technology of optical proximity correction and manufacturing method, which is applied in the direction of optics, pattern surface photolithography, and originals for photomechanical processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

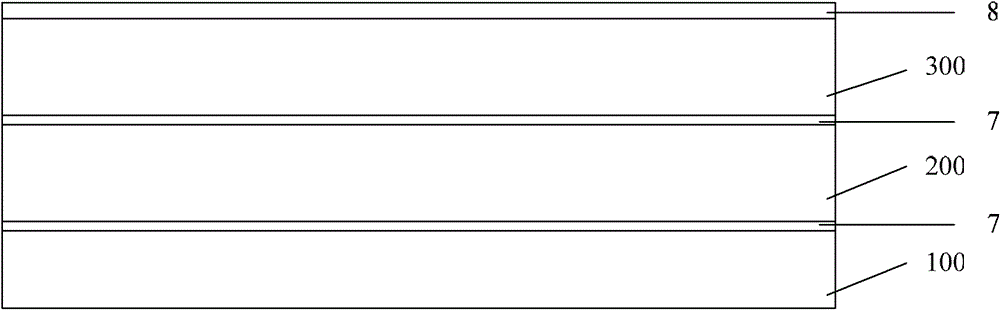

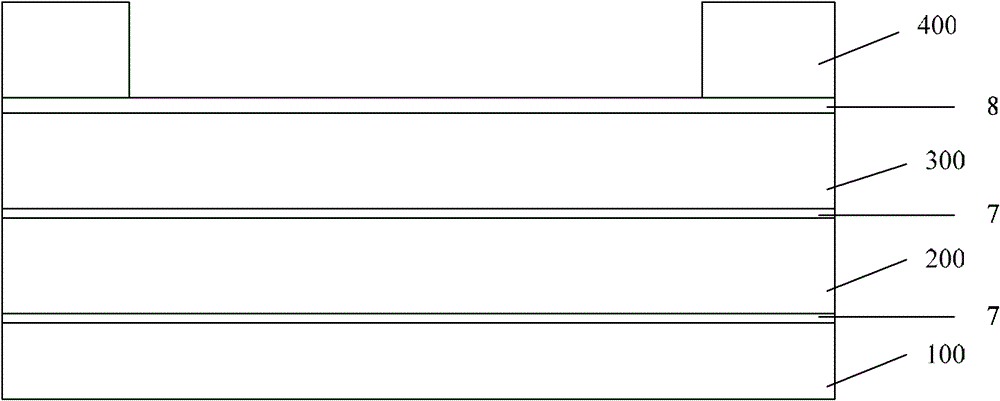

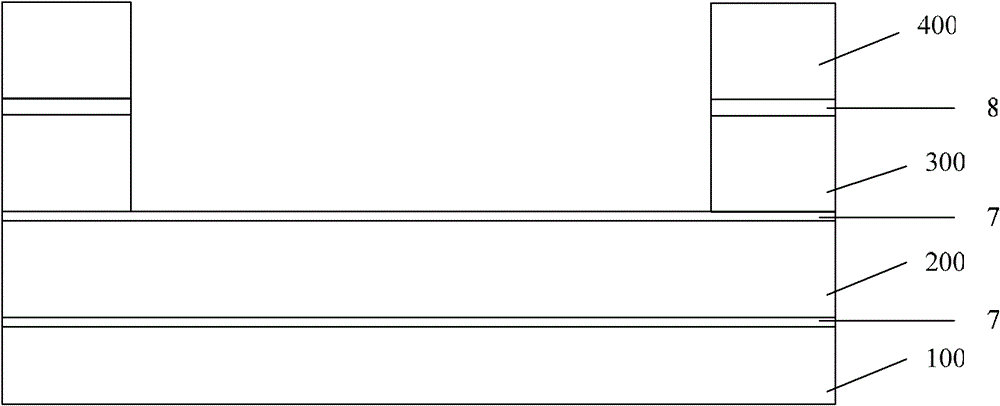

Method used

Image

Examples

Embodiment 1

[0075] Input customer's original layout data in OPC software, including V 1 layers and M 2 ADI target for each graph of the layer.

[0076] The process window of the lithography process includes two aspects: the depth of focus DOF and the exposure energy range, each of which has a tolerable error range, and the combined error range of the two aspects is the process window of the lithography process. to V 1 Continuously do about 10 iterations of OPC correction and simulation cycles to find graphics with a small process window; sort and classify these weak graphics themselves and the characteristics of the surrounding environment to form a weak graphics library;

[0077] Compare these positions with M 2 Compared with the target layer of the layer, check its connection relationship, if a certain V is found 1 V 1 The ADI of the layer increases;

[0078] In one embodiment, calling out V 1 layers and M 2 Layer mask layout information, compare the coordinate information of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com