A kind of white light LED chip manufacturing method and product thereof

A technology of LED chips and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of inconsistent color temperature, uneven coating surface, uneven color of white light, etc., to achieve the effect of consistent color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

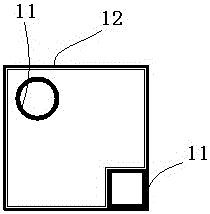

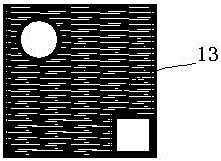

[0027] The invention discloses a method for manufacturing a white light LED chip, the whole process is combined as Figure 1-Figure 4 shown, including the following steps:

[0028] Step 1. Growing a complete LED epitaxial structure on the substrate: using organic chemical vapor deposition method to epitaxially grow the N-type electrode contact layer, the light-emitting active region, and the P-type electrode contact layer in sequence on the sapphire substrate;

[0029] Step 2, making the N-type electrode area: using photoresist or dielectric film as a mask, etching the designed N-type contact area and segmented area to the N-type contact electrode area on the P-GaN by ion etching;

[0030] Step 3, making a transparent conductive layer: making a transparent conductive layer on the surface of P-GaN by photolithography and vapor deposition, and annealing at 400°C-600°C for 10-30 minutes;

[0031] Step 4, making electrodes: use photoresist as a mask, vapor-deposit multi-layer met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com