Optical converting structure and led packing structure employing the optical converting structure

A technology of packaging structure and light conversion, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as poor luminous efficiency and mutual absorption of excitation light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

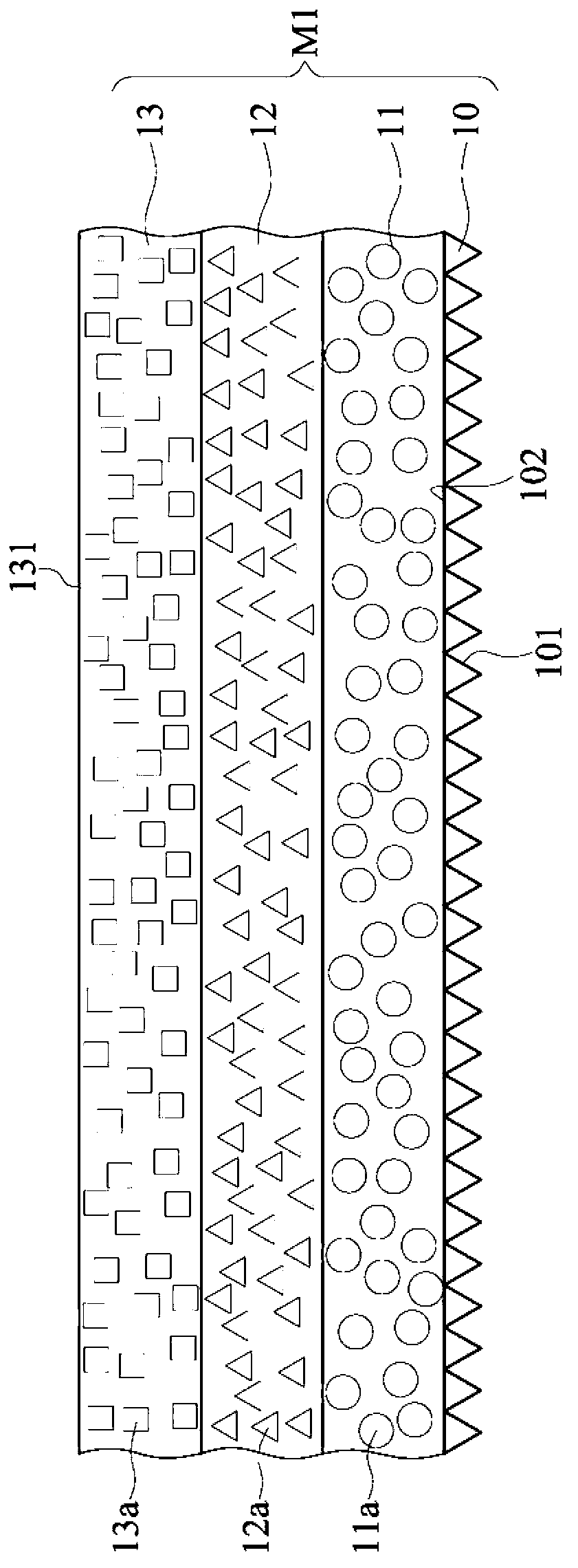

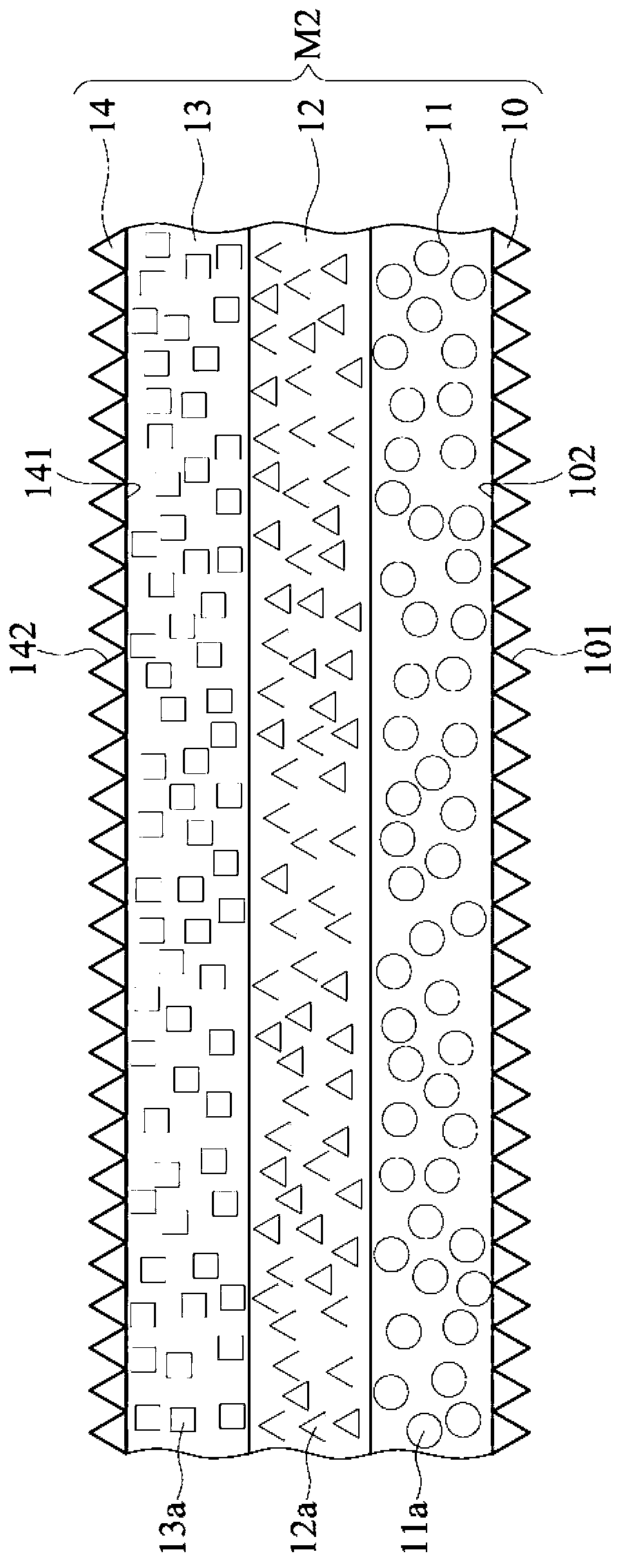

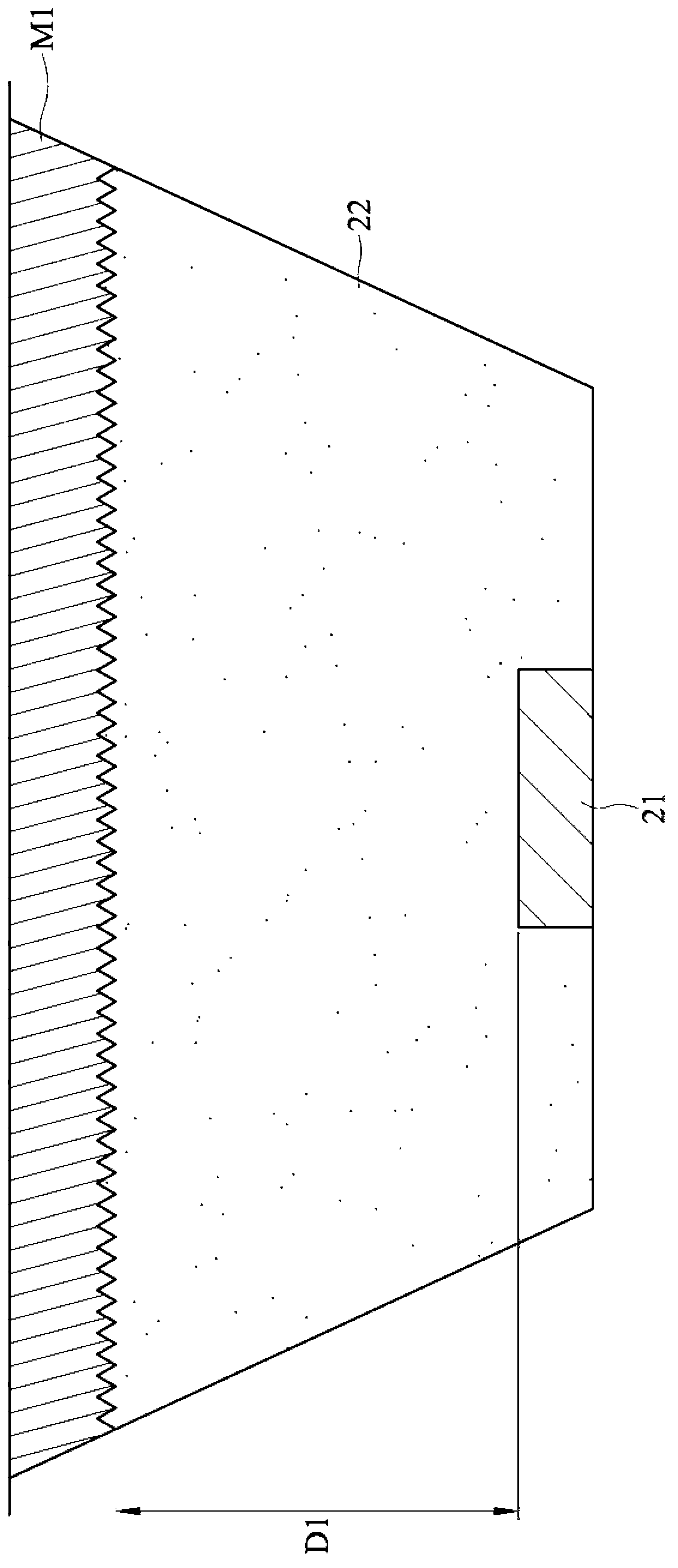

[0032] Please refer to Figure 1A , which is a schematic cross-sectional view of a light conversion structure according to an embodiment of the present invention. The light conversion structure M1 of this embodiment includes a first microstructure layer 10 and a plurality of phosphor layers (shown as phosphor layers 11 to 13 , but not limited to the present invention). The phosphor layers 11 to 13 are stacked to form a stacked structure. The first microstructure layer 10 includes a first flat surface 102 and a first rough surface 101 . The stack structure is disposed on the first flat surface 102 of the first microstructure layer 10 .

[0033] When light enters the first microstructure layer 10 from the first rough surface 101 of the first microstructure layer 10, since the refractive index inside the light conversion structure M1 is different from that outside the light conversion structure M1, and the first rough The surface 101 can change the incident angle of the light, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com