Column chromatography device with warning function

A column chromatography and functional technology, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve problems such as failure to alarm, excessive liquid material, etc., to achieve convenient operation, increase utilization rate, and equipment cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

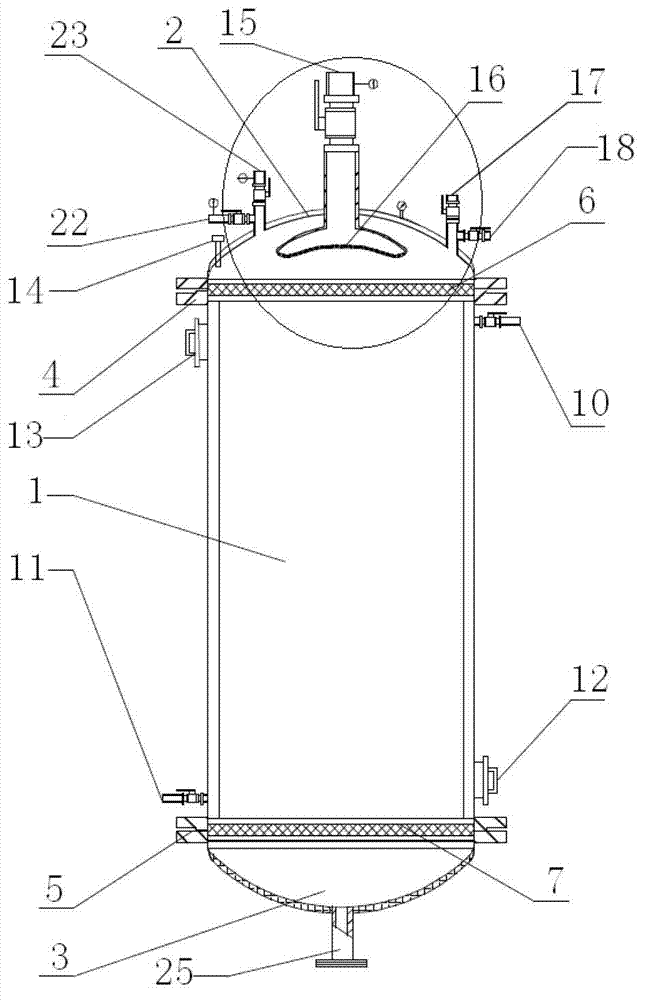

[0039] The column chromatography device proposed by the present invention is used in conjunction with a feed liquid storage tank, a heat exchanger, and a heat preservation and heating storage tank.

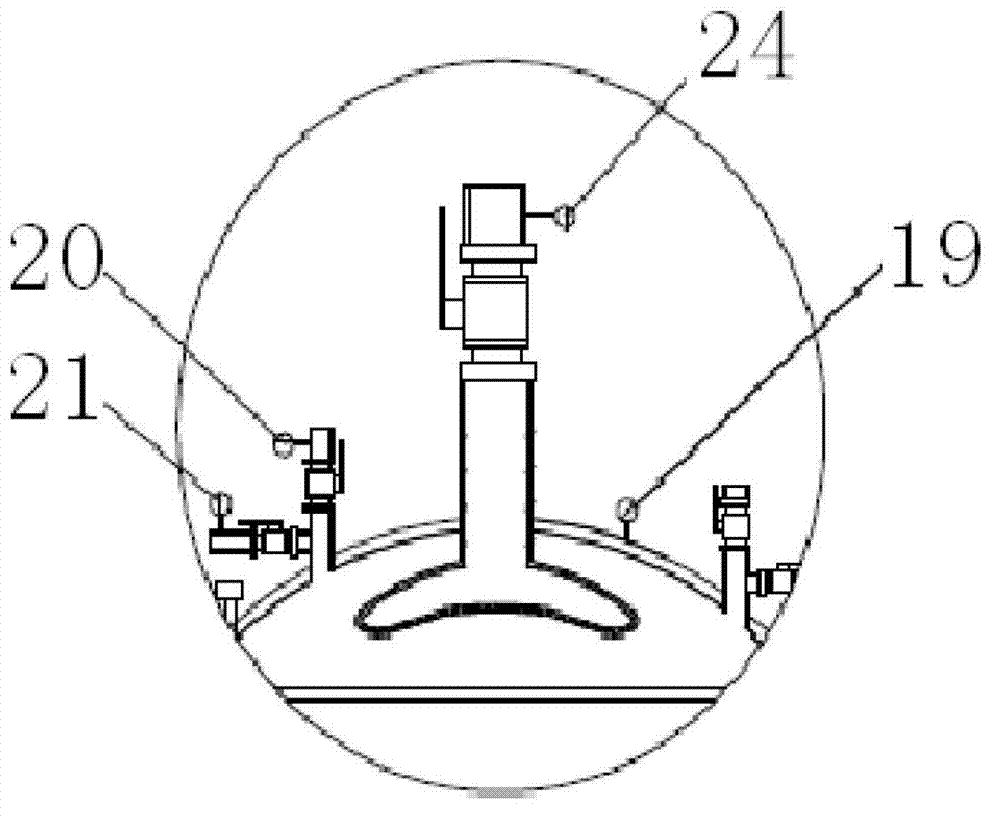

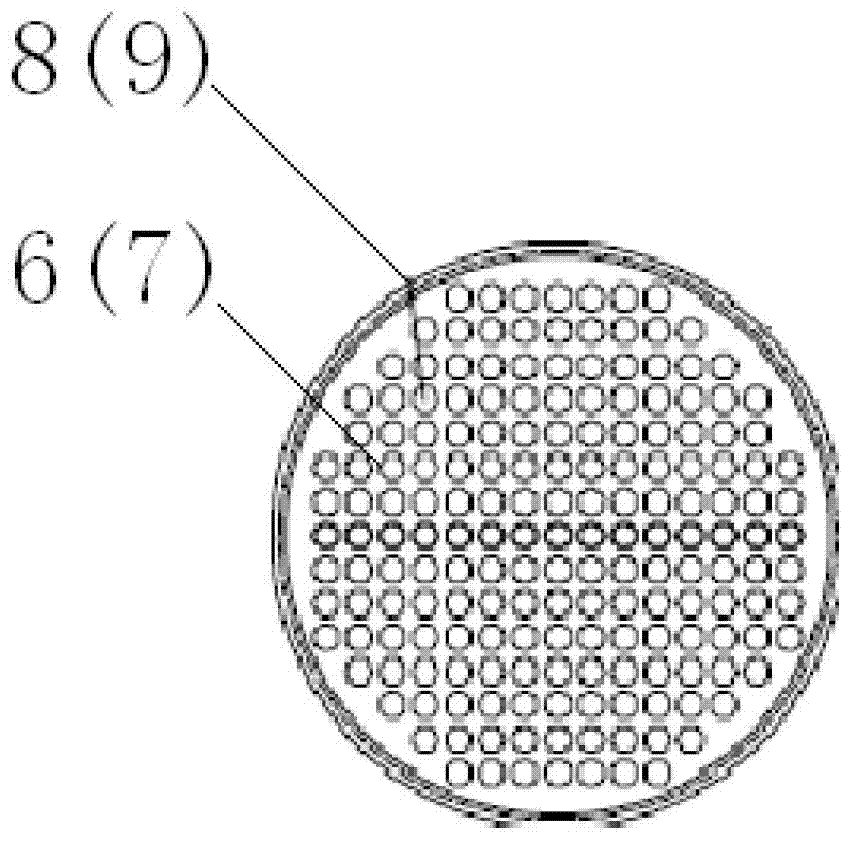

[0040] When washing liquid: firstly, the feed liquid is put into the heat exchanger from the feed liquid storage tank for preheating, and the feed liquid after preheating is stored in the heat preservation and heating storage tank; Port 15 and nozzle-type liquid distributor 16 enter the column chromatography device. Before feeding, the decompression port 23 in the column chromatography device should be connected to the vacuum pipeline; The redistribution of the first punching sieve plate 6 evenly passes through the macroporous resin, and the separated objects are absorbed and analyzed on the macroporous resin, and the impurities and eluents of different components move downward respectively, and flow into them through the second punching sieve plate 7. The lower head 3 flows out o...

Embodiment 2

[0045] The column chromatography device proposed by the present invention is used in conjunction with a feed liquid storage tank, a heat exchanger, and a heat preservation and heating storage tank.

[0046] When washing liquid: firstly, the feed liquid is put into the heat exchanger from the feed liquid storage tank for preheating, and the feed liquid after preheating is stored in the heat preservation and heating storage tank; Port 15 and nozzle-type liquid distributor 16 enter the column chromatography device, and the pressurization port 22 in the column chromatography device should be connected with the pressurization equipment before feeding; the feed liquid dispersed by nozzle-type liquid distributor 16 is passed through The redistribution of the first punched sieve plate 6 evenly passes through the ion resin, and the separated objects are absorbed and analyzed on the ion resin, and the impurities and eluents of different components move downward respectively, and flow dow...

Embodiment 3

[0051] The column chromatography device proposed by the present invention is used in conjunction with a feed liquid storage tank, a heat exchanger, and a heat preservation and heating storage tank.

[0052] When washing liquid: firstly, the feed liquid is put into the heat exchanger from the feed liquid storage tank for preheating, and the feed liquid after preheating is stored in the heat preservation and heating storage tank; Port 15 and nozzle-type liquid distributor 16 enter the column chromatography device. Before feeding, the decompression port 23 in the column chromatography device should be connected to the vacuum pipeline; The redistribution of the first punched sieve plate 6 evenly passes through the polyamide resin, and the separated objects are absorbed and analyzed on the polyamide resin, and the impurities and eluents of different components move downward respectively, and flow into The lower head 3 flows out of the column chromatography device through the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com