Liquid crystal anti-glaring rearview mirror

An anti-glare and rearview mirror technology, which is applied in the field of automobile rearview mirrors, can solve the problems of high process complexity and achieve the effect of large visual range and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

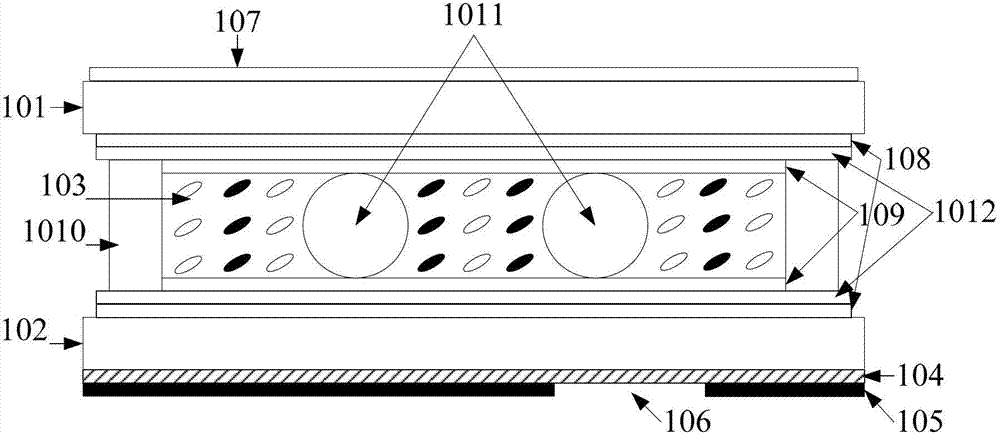

[0035] Such as figure 1 As shown, the liquid crystal anti-glare rearview mirror provided in this embodiment includes:

[0036] A first substrate 101, a second substrate 102, and a liquid crystal layer 103 encapsulated between the two substrates, the side of the first substrate 101 facing away from the liquid crystal layer 103 is a mirror surface;

[0037]The first substrate 101 and the second substrate 102 are transparent substrates, preferably glass substrates. Wherein, the side of the first substrate 101 facing away from the liquid crystal layer 103 is a mirror surface, that is, the first substrate 101 is a mirror surface for observation of a liquid crystal anti-glare rearview mirror, and is a mirror surface of a liquid crystal anti-glare rearview mirror. A surface near the driver. Correspondingly, the second substrate 102 is a reflective surface of the liquid crystal anti-glare rearview mirror, used for integrating structures such as reflective films or display modules, a...

Embodiment 2

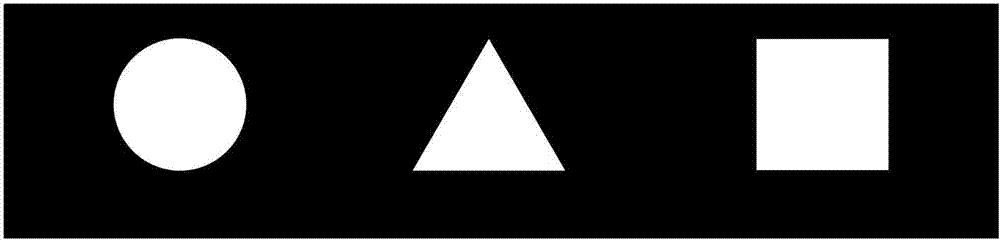

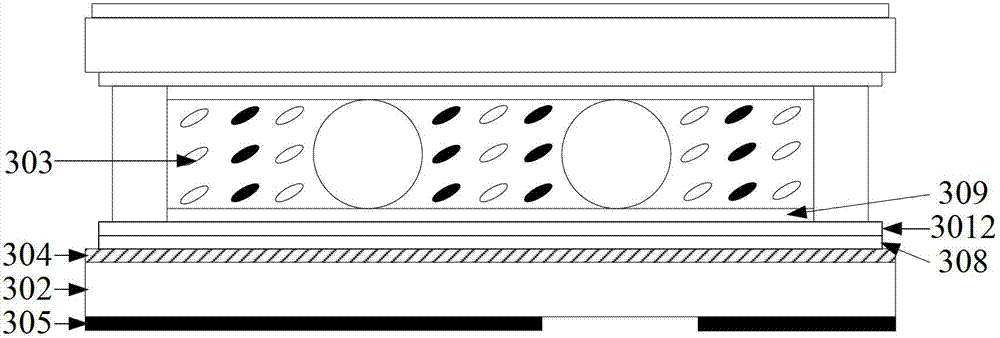

[0051] Such as Figure 4 As shown, the liquid crystal anti-glare rearview mirror provided in Embodiment 2 not only includes the various components of the liquid crystal anti-glare rearview mirror described in Embodiment 1, but also includes a display located in the window 406 area of the black film 405 407 , the shape of the display 407 is the same as the shape of the window 406 of the black film 405 . In the production process of this liquid crystal anti-glare rearview mirror, it is only necessary to integrate the display 407 and the window 406 of the black film 405 at the rear of the above-mentioned liquid crystal anti-glare rearview mirror to form the LCD anti-glare rearview mirror. A liquid crystal anti-glare rearview mirror with a display.

[0052] It should be noted that, for ease of description, this embodiment introduces this liquid crystal anti-glare rearview mirror by taking the structure in which the semi-transmissive and semi-reflective layer is arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com