Bi2Fe4O9 multiferroic ceramic material and preparation method thereof

A technology of multiferroic ceramics and ferric nitrate, which is applied in the field of information functional materials, can solve the problems that there are no reports on multiferroic ceramics, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

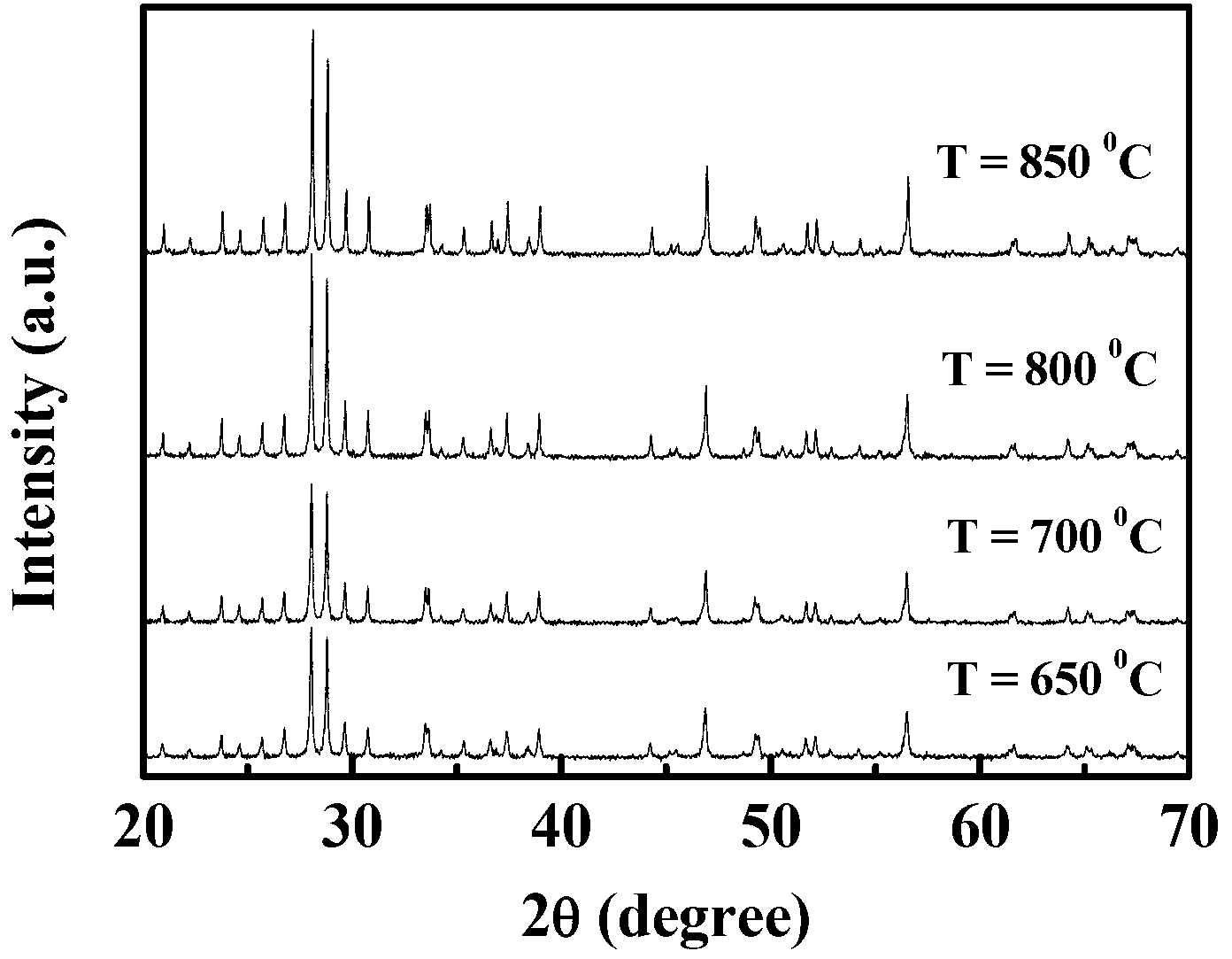

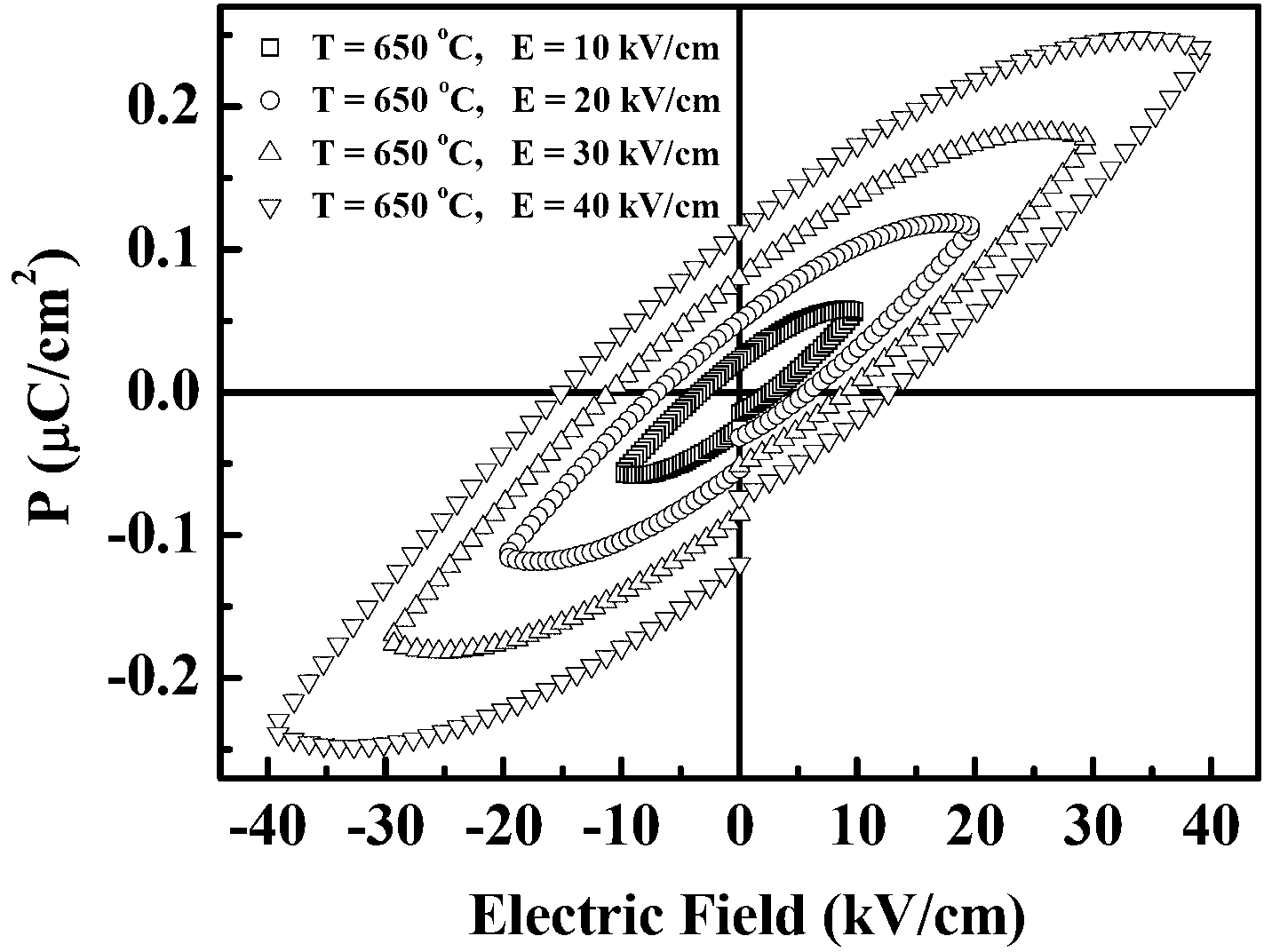

Embodiment 1

[0025] Prepared by the citric acid-nitrate sol-gel self-propagating combustion reaction method, after the 0.35T magnetic field treatment, the annealing temperature is 650 ℃ Bi sintered in the air 2 Fe 4 o 9 multiferroic ceramics. In the first step, weigh 0.12mol of citric acid and put it into a 100mL beaker, add 30mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of ferric nitrate and add it to the above solution to dissolve under constant stirring. After being dissolved, weigh 0.02mol of bismuth nitrate and add to the above solution and dissolve; under ultrasonic dispersion, add 8ml of ethylene glycol to form a transparent solution; wherein, the molar ratio of citric acid to the sum of the above two metals is 1.5 :1. In the second step, under the condition of constant stirring, the pH value was adjusted to 7 with ammonia water, and the mixed solution was aged in a water bath for 10 hours. Then, evaporate ...

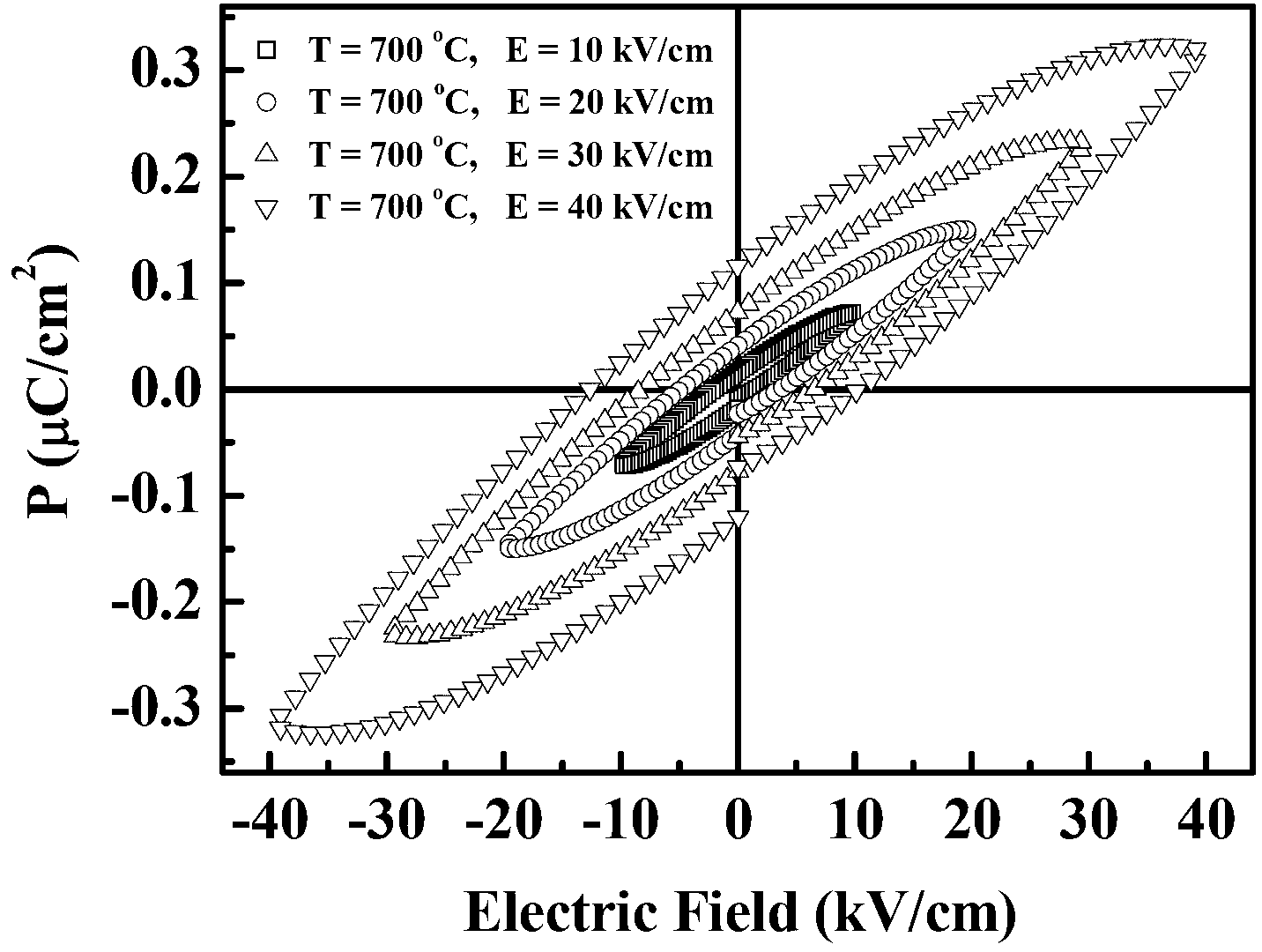

Embodiment 2

[0028] Prepared by citric acid-nitrate sol-gel self-propagating combustion reaction method, after 0.4T magnetic field treatment, the annealing temperature is 700 ℃ Bi sintered in air 2 Fe 4 o 9 multiferroic ceramics. In the first step, weigh 0.12mol of citric acid and put it into a 100mL beaker, add 30mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of ferric nitrate and add it to the above solution to dissolve under constant stirring. After being dissolved, weigh 0.02mol of bismuth nitrate and add to the above solution and dissolve; under ultrasonic dispersion, add 8ml of ethylene glycol to form a transparent solution; wherein, the molar ratio of citric acid to the sum of the above two metals is 2 :1. In the second step, under constant stirring, the pH value was adjusted to 7 with ammonia water, and the mixed solution was aged in a water bath for 11 hours. Then, evaporate the solution to dryness in a wat...

Embodiment 3

[0031] Prepared by citric acid-nitrate sol-gel self-propagating combustion reaction method, after 0.4T magnetic field treatment, the annealing temperature is 800 ℃ Bi sintered in air 2 Fe 4 o 9 multiferroic ceramics. In the first step, weigh 0.12mol of citric acid and put it into a 100mL beaker, add 30mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of ferric nitrate and add it to the above solution to dissolve under constant stirring. After being dissolved, weigh 0.02mol of bismuth nitrate and add to the above solution and dissolve; under ultrasonic dispersion, add 8ml of ethylene glycol to form a transparent solution; wherein, the molar ratio of citric acid to the sum of the above two metals is 2 :1. In the second step, under constant stirring, the pH value was adjusted to 7 with ammonia water, and the mixed solution was aged in a water bath for 11 hours. Then, evaporate the solution to dryness in a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com