One-dose one-bath low-temperature type pre-treatment compound preparation

A compound preparation and low-temperature technology, which can be used in fiber treatment, bleaching products, textiles and papermaking, etc. It can solve the problems of affecting scouring and bleaching effects, high dosage of bleaching activators, and affecting process reproducibility, etc., and achieves good application. Effects of foreground, temperature reduction, and avoidance of inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

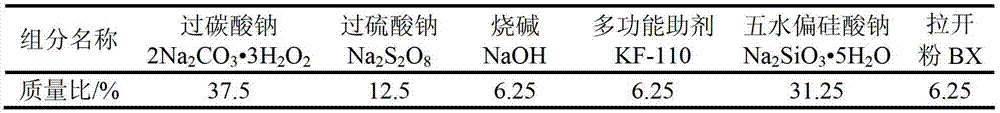

[0021] According to the proportions in Table 1, prepare one dose, one bath low-temperature pretreatment compound preparation:

[0022] Table 1

[0023]

Embodiment 2

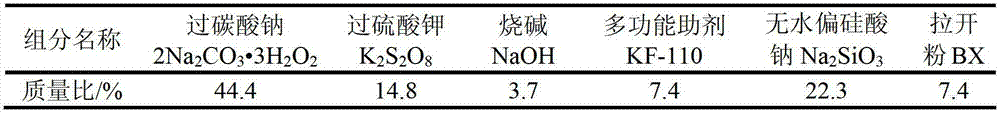

[0025] Prepare one potion one bath low temperature type pretreatment composite preparation according to the ratio in Table 2:

[0026] Table 2

[0027]

Embodiment 3

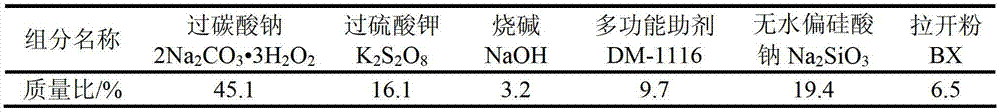

[0029] Prepare one dose, one bath low temperature pretreatment compound preparation according to the ratio in Table 3 below:

[0030] table 3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com