Low-temperature less-alkali pretreatment method for modified polyester/cotton blended knitted fabric

A modified polyester and cotton blending technology, applied in fiber processing, textile and papermaking, plant fibers, etc., can solve the problems of high production cost, environmental pollution, and large damage to modified polyester, and achieve the goal of reducing dosage and high efficiency. Effects of treatment, dosage reduction and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Fabric Variety: Modified polyester / cotton blend (80 / 20) knitted jersey

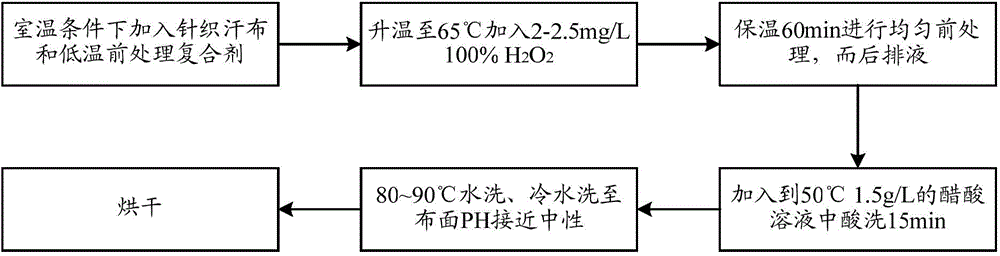

[0058] New process: short-process process of low-temperature and less-alkali hot soaking method

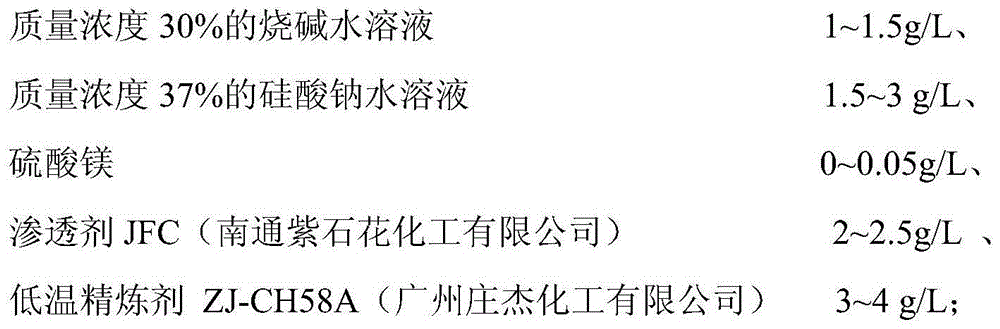

[0059] (1) Add the above-mentioned one-dose, one-bath low-temperature pretreatment compound preparation (30% caustic soda 1g / L, 37% sodium silicate 1.5g / L, magnesium sulfate 0.05g / L, infiltration Refining agent JFC 2g / L, low-temperature refining agent ZJ-CH58A 3g / L) and knitted gray fabric, the bath ratio is 1:10, heat up to 65°C, add 100% hydrogen peroxide 2g / L, keep warm for 60min, and obtain the bleached fabric;

[0060] (2) Put the above-mentioned bleached fabric into the glacial acetic acid solution, raise the temperature to 50°C, keep it warm for 10-15 minutes, drain the liquid after neutralizing the acid, and then use hot water at 80-90°C and warm water at 50-60°C in sequence. Wash with cold water (20-25°C) and dry at last. Test properties such as whiteness, capillary effect, and whiteness, an...

Embodiment 2

[0065] Fabric Variety: Modified polyester / cotton blend (65 / 35) knitted single jersey

[0066] New process: short-process process of low-temperature and less-alkali hot soaking method

[0067] (1) Add the above-mentioned one-dose, one-bath low-temperature pretreatment compound preparation (30% caustic soda 1g / L, 37% sodium silicate 1.5g / L, magnesium sulfate 0.05g / L, infiltration Refining agent JFC 2g / L, low-temperature refining agent ZJ-CH58A 3g / L) and knitted gray fabric, the bath ratio is 1:10, heat up to 65°C, add 100% hydrogen peroxide 2g / L, keep warm for 60min, and obtain the bleached fabric;

[0068] (2) Put the above-mentioned bleached fabric into the glacial acetic acid solution, raise the temperature to 50°C, keep it warm for 10-15 minutes, drain the liquid after neutralizing the acid, and then use hot water at 80-90°C and warm water at 50-60°C in sequence. Wash with cold water (20-25°C) and dry at last. Test properties such as whiteness, capillary effect, and whitenes...

Embodiment 3

[0073] Fabric Variety: Modified polyester / cotton blend (35 / 65) knitted single jersey

[0074] New process: short-process process of low-temperature and less-alkali hot soaking method

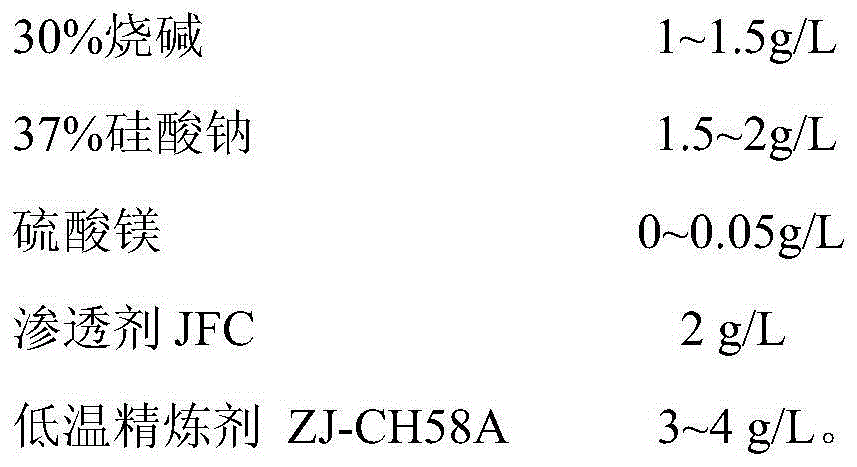

[0075] (1) Add the above-mentioned one-dose, one-bath low-temperature pretreatment compound preparation (30% caustic soda 1.5g / L, 37% sodium silicate 2g / L, magnesium sulfate 0.05g / L, infiltration Refining agent JFC2g / L, low-temperature refining agent ZJ-CH58A4g / L) and knitted gray fabric, the bath ratio is 1:10, heat up to 65°C, add 100% hydrogen peroxide 2.5g / L, keep warm for 60min, and obtain the bleached fabric;

[0076] (2) Put the above-mentioned bleached fabric into the glacial acetic acid solution, raise the temperature to 50°C, keep it warm for 10-15 minutes, drain the liquid after neutralizing the acid, and then use hot water at 80-90°C and warm water at 50-60°C in sequence. Wash with cold water (20-25°C) and dry at last. Test properties such as whiteness, capillary effect, and whiten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com