Cushion block assembly structure for jacking structure and jacking implementation method of cushion block assembly structure

A technology for structures and pads, which is applied to the assembly structure of pads for structure jacking and its jacking implementation field, can solve the problems of difficulty in transporting and installing pads, limited on-site operating space for large bridges, and bulkiness, etc. The method is simple, convenient and reliable, overcomes the difficulty of production, and has good construction safety effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

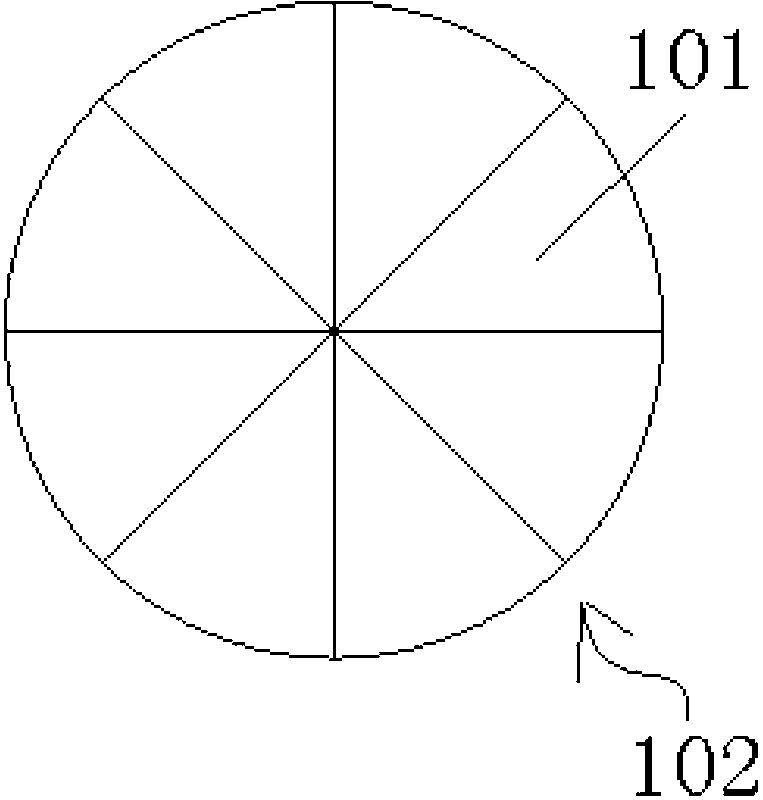

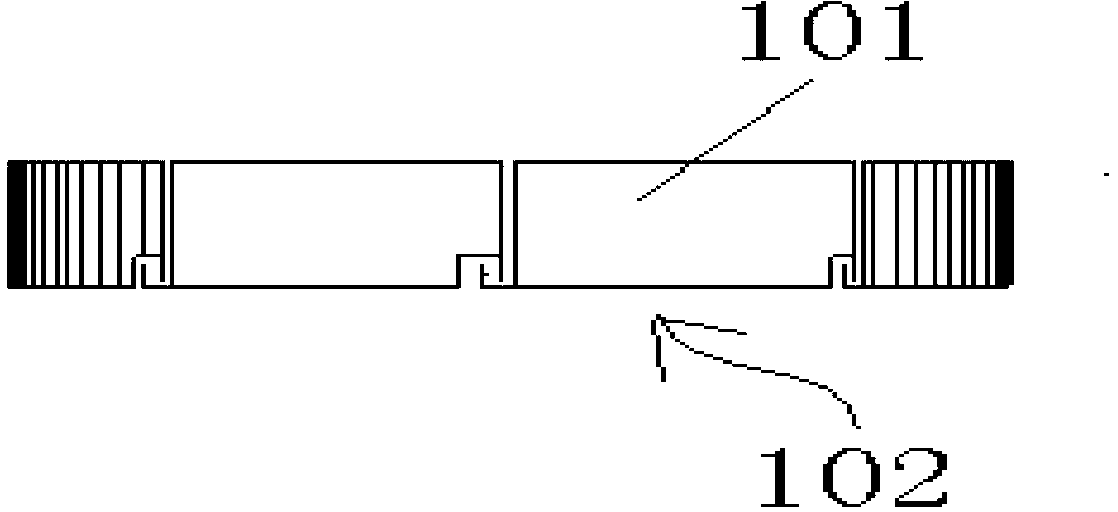

[0037] As shown in the figure, this embodiment proposes a pad assembly structure for structure jacking, including: a pad layer formed by assembling a number of special-shaped pads, and a number of pad layers are stacked vertically to form the lifting structure of the structure. Assemble the structure with pads; the special-shaped pad includes an enclosure plate for enclosing and constructing the shape of the special-shaped pad, the enclosure plate is filled with concrete, and the splicing surface of the enclosure plate is provided with a tongue and groove, A groove-and-groove connection is provided between adjacent special-shaped pads on the same pad layer.

[0038] As a further specific implementation of this embodiment, tunnels for penetrating prestressed tendons are pre-embedded in the pad layer, and prestressed tendons for enhancing the tightness between the special-shaped pads are arranged in the tunnels. The upper and lower ends of the enclosure plate are arranged with r...

Embodiment approach

[0040] The jacking implementation method of the structure jacking pad assembly structure of the present embodiment comprises the following steps:

[0041] Step 1: Assembling several of the special-shaped pads into a pad layer suitable for the cross-section of the installation pier column; wherein, the adjacent special-shaped pads are tightly lapped and fixed through the tongue and groove between the enclosure plates position, and the pre-stressed tendons are stretched and anchored in the channels pre-embedded in the pads, so as to realize the pre-compression between the pads.

[0042] Step 2: superimposing the spacer layer on the jacking installation surface of the installation pier to complete the lifting of the installation pier.

[0043] As a further specific implementation of this embodiment, after step 2 is completed, it also includes: if the section of the assembled pad layer is smaller than the section of the original pier column, when it needs to be determined that the...

Embodiment 2

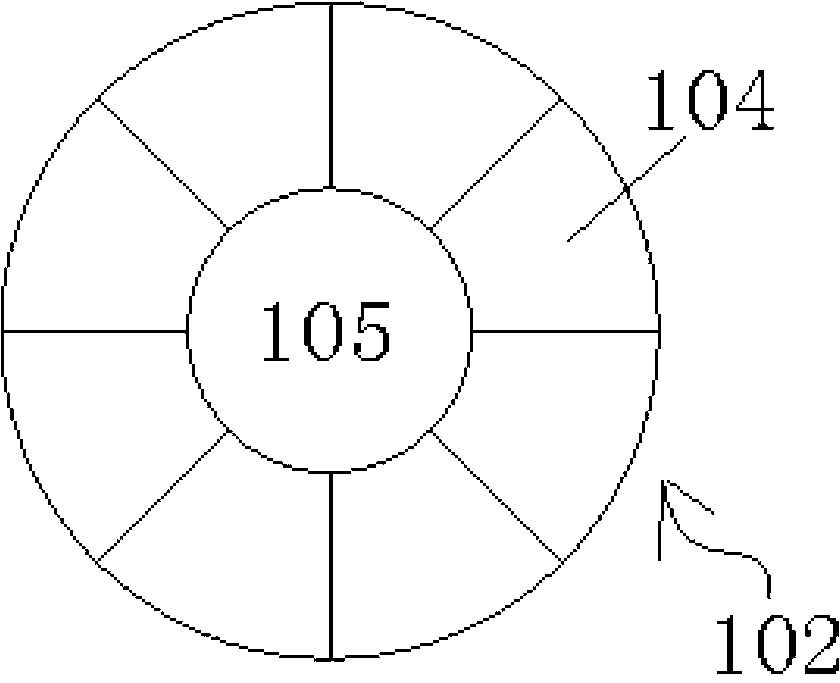

[0052] Figure 2a It is the attached view of the assembled structure of the cushion blocks for structure jacking in the second embodiment. Figure 2b It is the elevation view of the assembled structure of the cushion block used for lifting the structure of the second embodiment. In order to better adapt to the non-circular cross-section of the installation pier column, the difference from the first embodiment is that the structure jacking pad assembly structure of the present embodiment The special-shaped pads include: Figure 2a The L-shaped spacer 201 and the T-shaped spacer 202 are matched with each other, and the L-shaped spacer 201 and the T-shaped spacer 202 are interlocked and assembled to form a spacer layer 203 with a rectangular cross-section. Specifically, two L-shaped spacers 201 and one T-shaped spacer 202 are buckled together, and the L-shaped spacer 201 is fastened to the left and right sides of the T-shaped spacer 202 .

[0053] In addition, the channel 204 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com