Plastic thickness measuring device based on plane capacitive sensor and method thereof

A capacitive sensor and sensor technology, applied in the field of capacitive sensing, can solve the problems of high price, large fragmentation, slow response speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

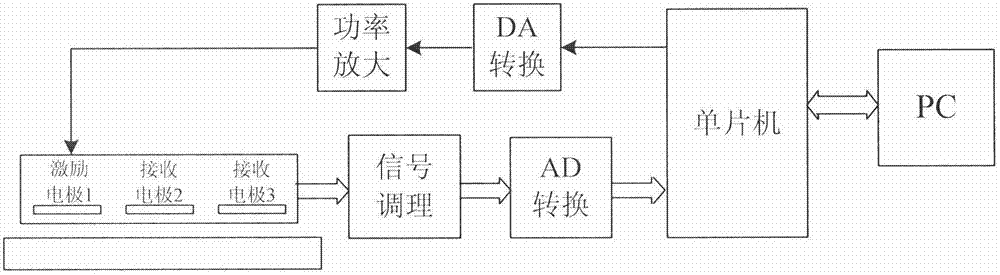

[0014] figure 1 It is a structural block diagram of a detection device drawn according to an embodiment of the present invention. Including capacitive sensor, D / A and A / D conversion circuit, power amplification and signal conditioning circuit, single chip microcomputer, upper computer 5 parts.

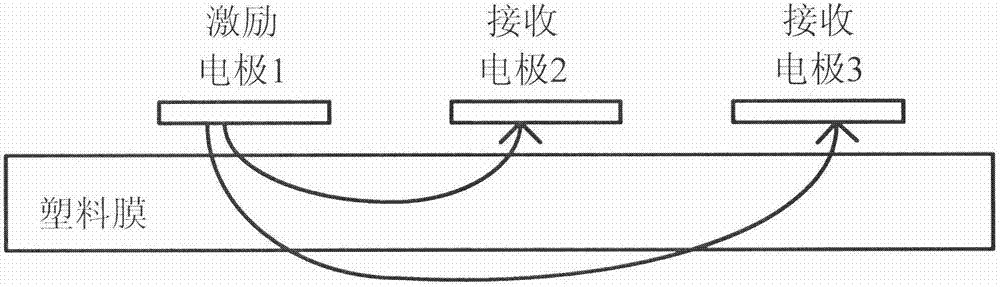

[0015] The capacitive sensor is composed of 3 sets of identical electrode plates. The electrodes are made of metal light foil with a thickness of 0.001-1mm. The electrode size and spacing can be adjusted according to the thickness of the measured plastic film. Three sets of electrodes are located above the plastic film to be tested, and the electrode plane is parallel to the plastic film. One of the electrode plates is used as excitation, and the other two electrode plates are used as detection electrodes, such as figure 2 shown.

[0016] Assume figure 1 and figure 2 The capacitance value formed by electrode 1 and electrode 2 is C12, and the capacitance value formed by electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com