Calibration system and calibration method of alternating large current of current transformer

A current transformer, high current technology, applied in the field of current transformer AC high current verification system, can solve the problems of increasing the internal resistance of the hollow coil, output error, difficulty in ensuring the current measurement accuracy of the standard current channel, etc., to ensure the output Accuracy, high-precision AC high-current calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

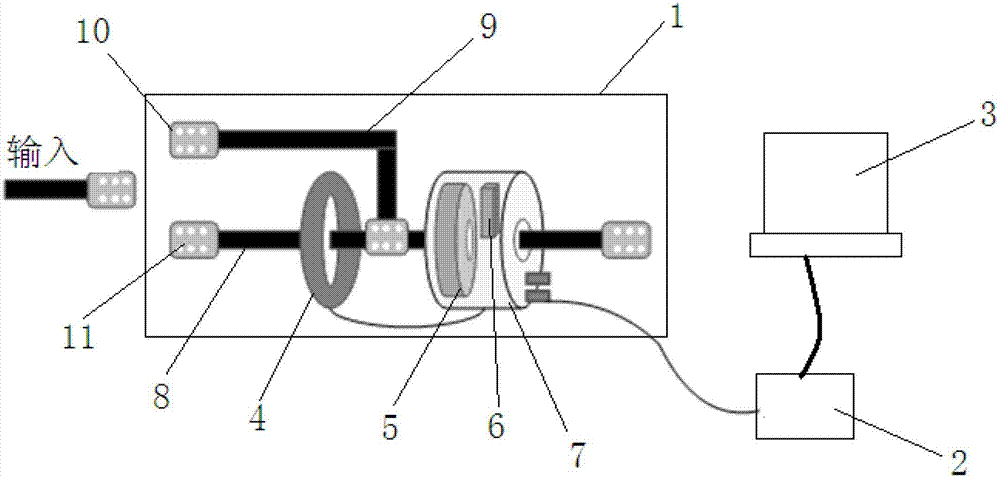

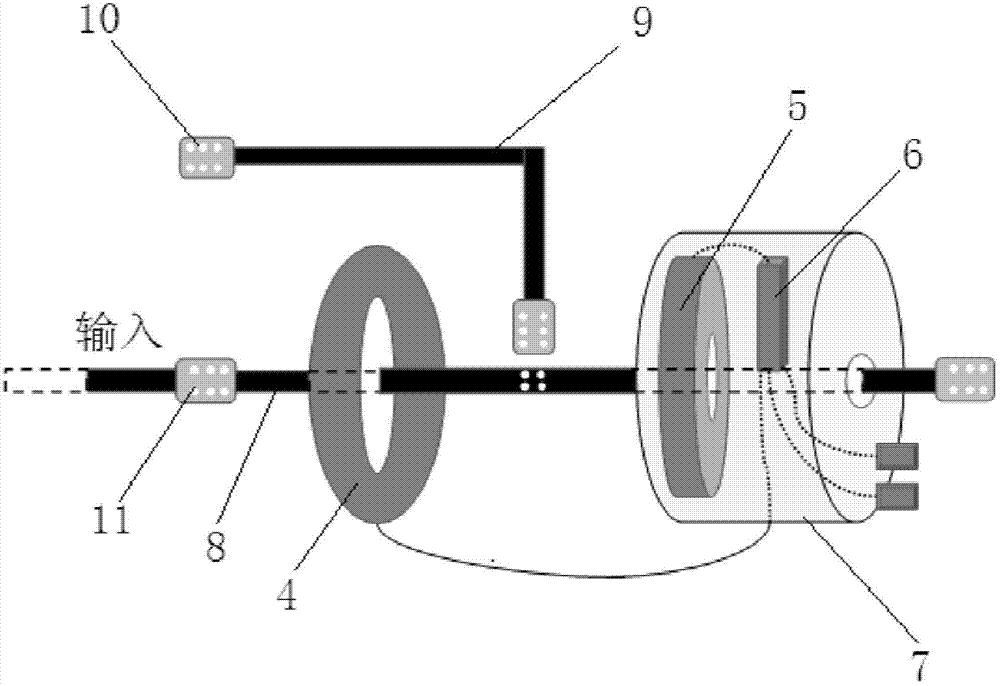

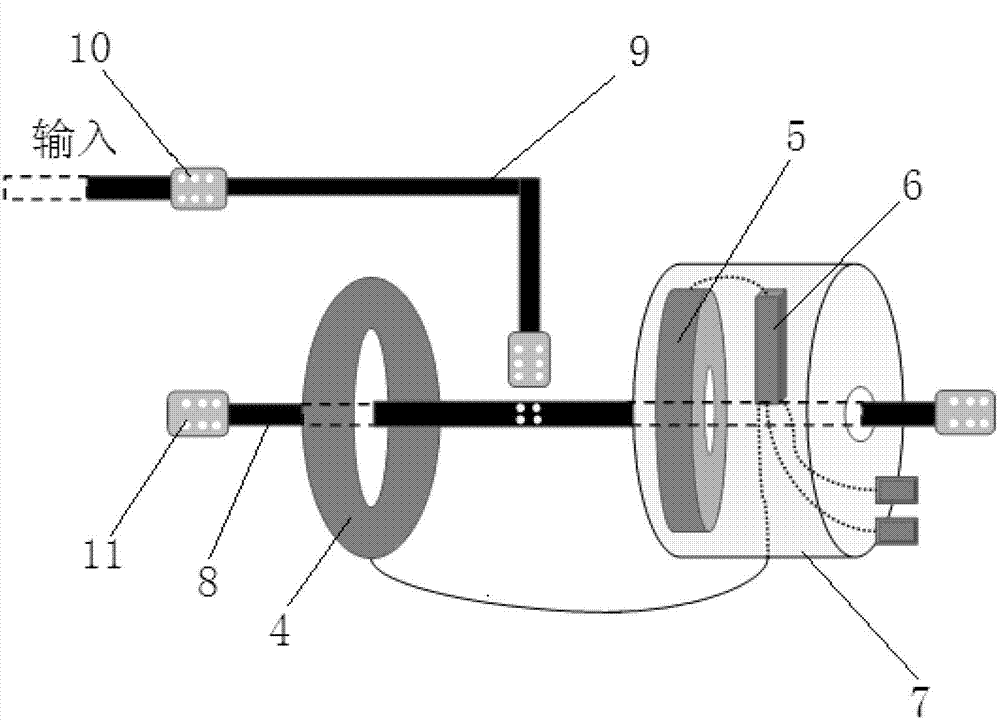

[0033] The current transformer AC large current verification system and method based on the verification of the air-core coil mutual inductance coefficient of the present invention uses the iron core coil to correct the mutual inductance coefficient of the installed air-core coil, judges whether the state of the air-core coil meets the verification conditions, and then passes The feedback of the mutual inductance coefficient of the air-core coil completes the closed-loop control during the calibration, realizes high-precision AC high-current calibration, and ensures the output accuracy of the air-core coil current transformer, such as figure 1 As shown, the AC large current calibration system of the current transformer of the present invention includes a large current sensing unit 1, a data acquisition unit 2 and a PC 3, and the large current sensing unit includes an ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com