Laser rotating direct-exposure imaging device and method used for revolution surface

An imaging device and a technology of a rotary surface, which are applied in photolithographic exposure devices, laser welding equipment, microlithography exposure equipment, etc., can solve problems such as low repeatability, no processing means, product repeatability, and consistency deviation. Achieve the effects of reasonable mechanical structure design, convenient use and operation, and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

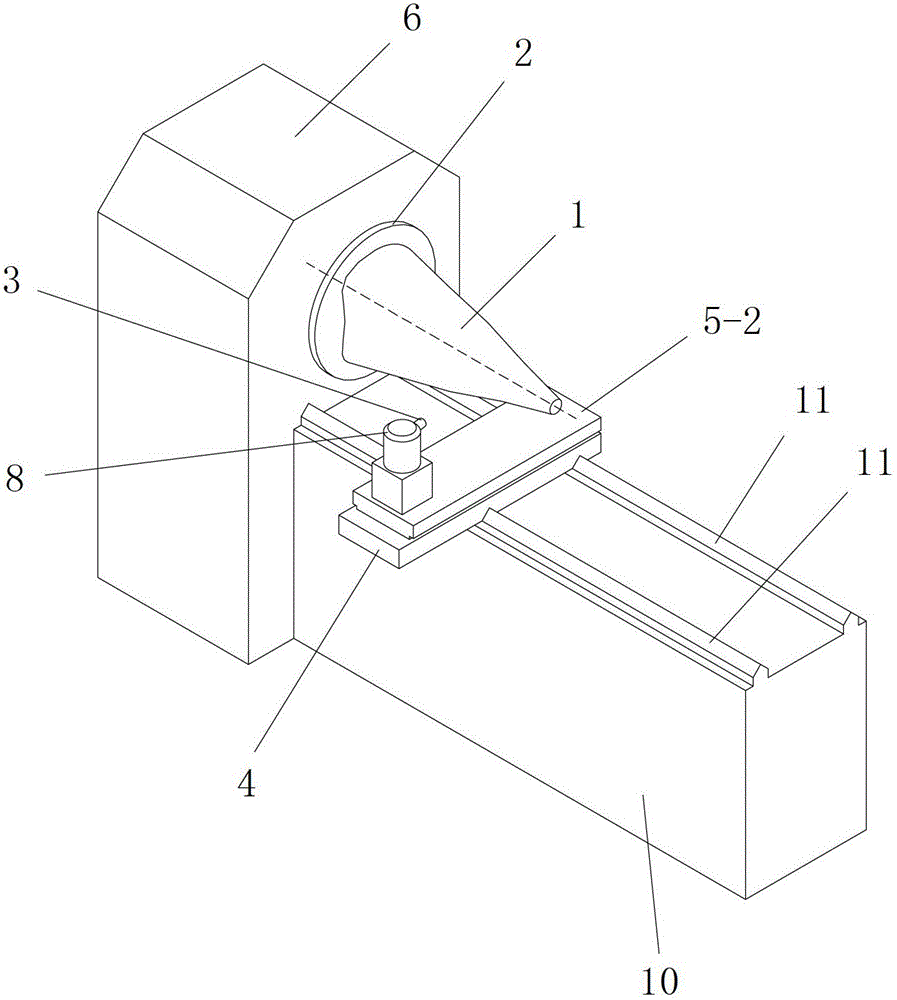

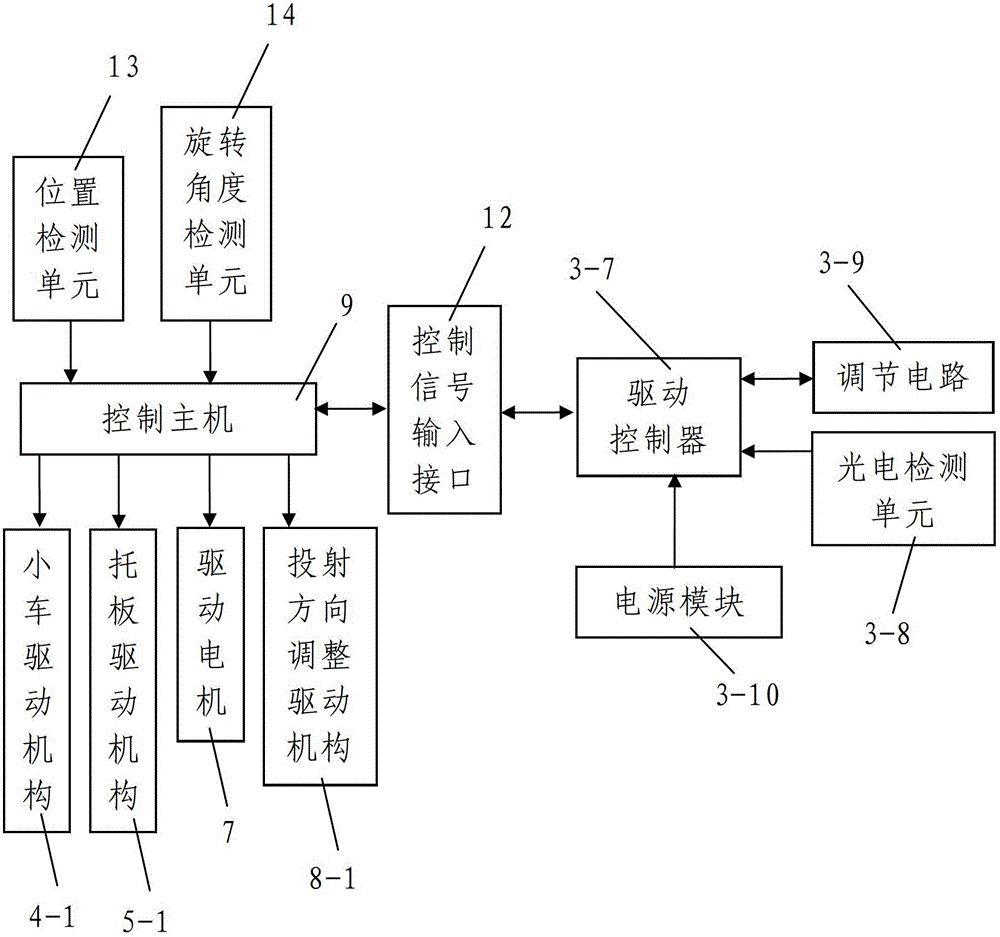

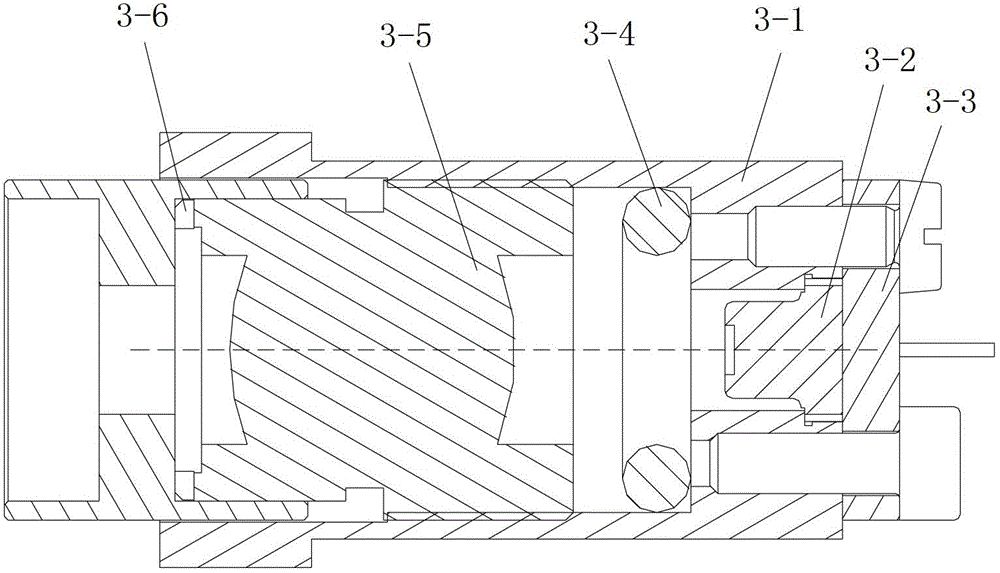

[0064] like figure 1 , figure 2Shown is a rotary surface direct exposure imaging device with laser rotation, including a rotating spindle 2 that drives the workpiece 1 to continuously rotate, and the photosensitive material coating coated on the outer surface of the workpiece 1 is rotated while performing exposure treatment And obtain the laser 3 for exposing and imaging patterns, the axial moving trolley 4 that drives the laser 3 to move back and forth along the central axis direction of the rotating spindle 2, and the vertical vehicle for adjusting the distance between the laser 3 and the corresponding exposure points on the outer surface of the workpiece 1 A moving pallet and a laser beam projection direction adjusting member installed on the vertically movable pallet and adjusting the projection direction of the laser beam emitted by the laser 3, one end of the rotating main shaft 2 and the power output shaft of the drive motor 7 transmission connection, and the workpiec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com