Self-checking circuit of preventing misoperation of wiring and working method thereof

A technology of self-test circuit and misoperation, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of ineffective safety circuit, inability to transmit real signals, endangering personnel safety, etc., to ensure Correctness, improved reliability, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

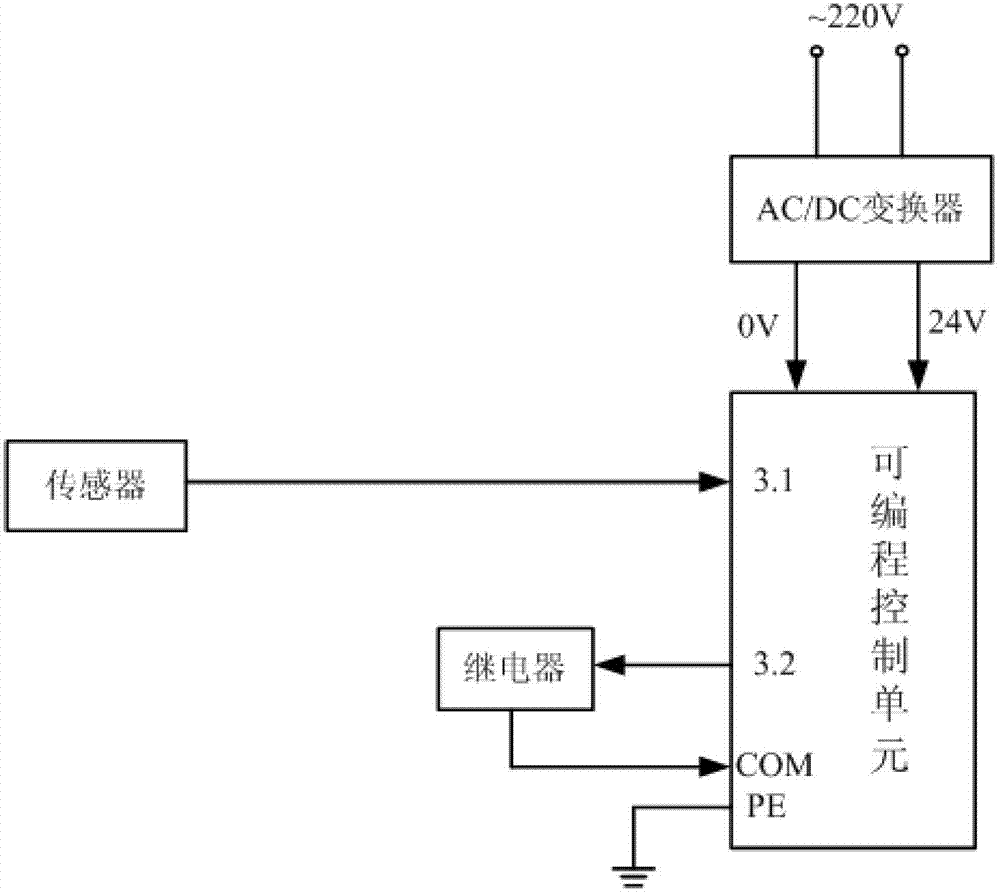

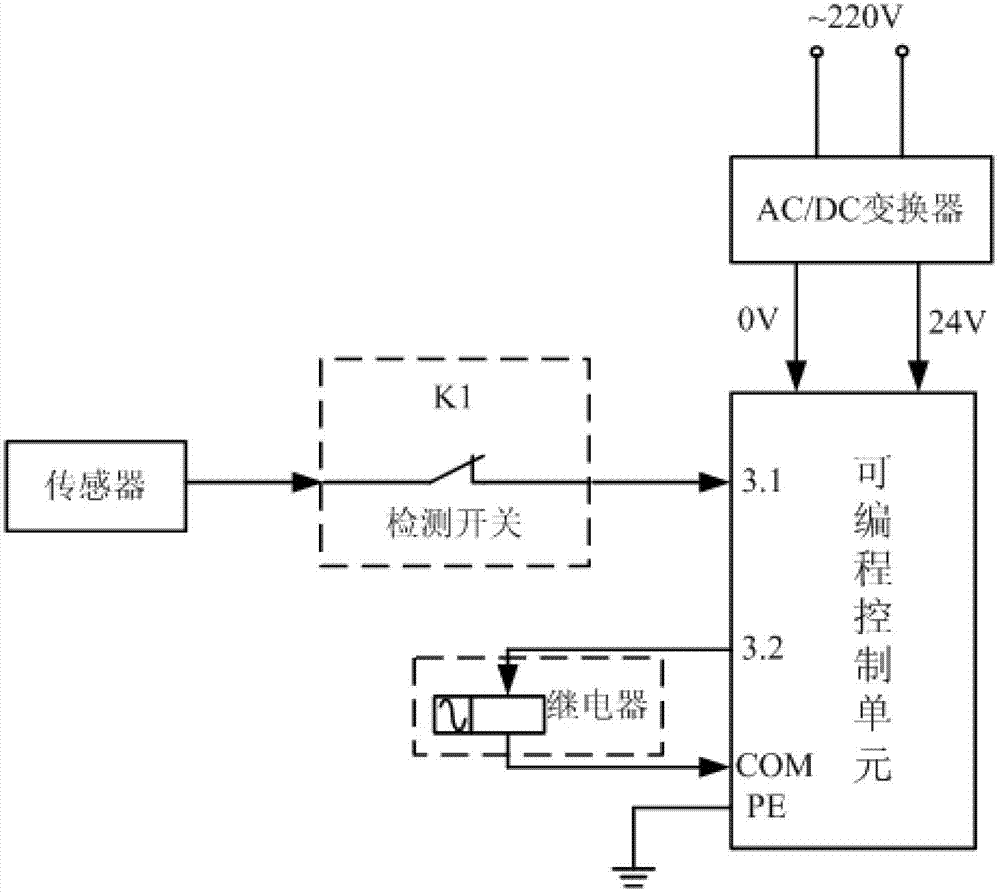

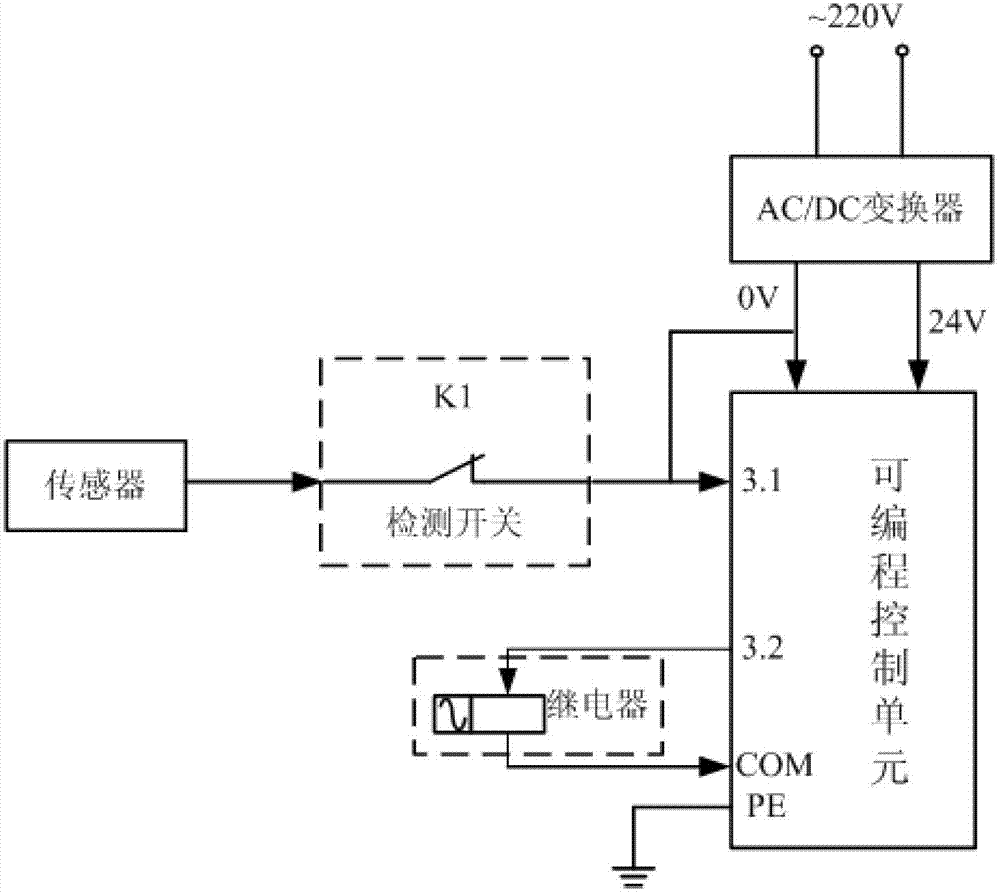

[0027] Embodiment: a kind of self-inspection circuit (see figure 2 ), including an AC power supply, an AC / DC converter, a sensor, a relay and a programmable control unit, wherein the AC / DC converter converts the AC power of the AC power supply into a direct current and is connected to the power supply terminal of the programmable control unit; the sensor The output terminal of the programmable control unit is connected to the level input terminal 3.1 of the programmable control unit; the output terminal 3.2 of the programmable control unit is connected to the COM port of the programmable control unit through a relay; it is characterized in that it also includes a detection switch K1, and is connected to Between the sensor and the programmable control unit level input 3.1.

[0028] The programmable control unit is PLC.

[0029] The sensors are industrial sensors.

[0030] The relays are Omron MY-D2 series.

[0031] The detection switch K1 is a normally closed switch that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com