Orthotropic piezoelectric sensor for monitoring/detection of civil engineering structure, preparation method thereof and application thereof

A piezoelectric sensor, orthotropic technology, application in material selection for piezoelectric or electrostrictive devices, fabrication/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive Devices, etc., can solve the problems of measuring stress and stress waves, etc., and achieve obvious orthotropic characteristics, improve signal-to-noise ratio, and good orthotropic characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

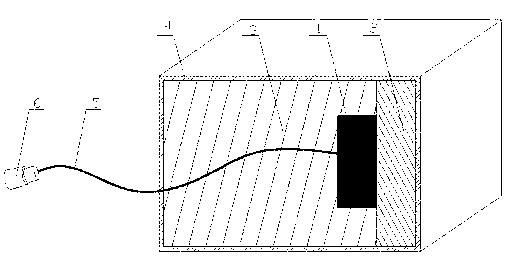

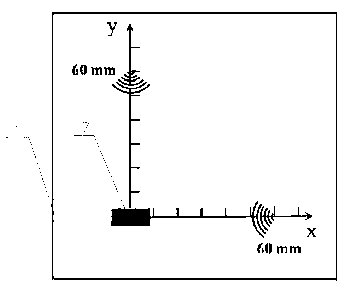

[0032] The manufacturing process of the present invention is divided into the following parts: (1) preparation of 1-3 type orthotropic piezoelectric composite materials; (2) preparation of matching layer; (3) preparation of backing layer (also called package); (4) shielding treatment.

[0033] (1) Preparation of type 1-3 orthotropic piezoelectric composites

[0034] Prepare 1-3 type orthotropic polymer / cement-based piezoelectric composites or 1-3 type orthotropic cement-based piezoelectric composites by combining cutting-casting and alignment-casting methods, with PZT-5 piezoelectric Ceramic is the piezoelectric phase, a mixture of epoxy resin (AB-grouting resin) and cement (sulfoaluminate cement) or cement (sulfoaluminate cement) as a matrix, using conductive glue to form interdigitates inside the piezoelectric composite type electrodes, forming an interdigitated structure. The structural parameters and component parameters of the obtained piezoelectric composite material a...

Embodiment 2

[0071] 1. Preparation of Type 1-3 orthotropic polymer / cement-based piezoelectric composite material according to the method of Example 1;

[0072] 2、 Connecting the orthotropic piezoelectric element to the wire, the positive and negative poles of the piezoelectric element are respectively connected to the wire, and a part of the wire is drawn from the wire connected to the negative electrode of the orthotropic piezoelectric element as a shielding wire;

[0073] 3. Prepare the matching layer according to the method in Example 1, except that the mass ratio of cement, epoxy resin and tungsten powder is 3:3:1, and the mass ratio of curing agent to epoxy resin is 4:1;

[0074] 4. Prepare a backing layer according to the method of Example 1.

[0075] 5. Prepare the shielding layer according to the method in Example 1.

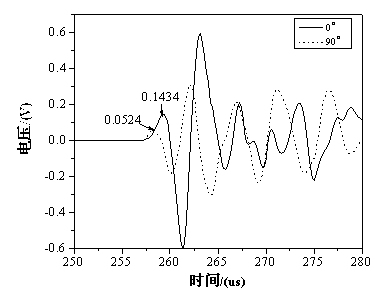

[0076] Performance tests were performed on the obtained sensor, and its orthotropic characteristics, sensitivity, bandwidth and other performances were similar to ...

Embodiment 3

[0078] Orthotropic piezoelectric sensors are prepared according to the method of Example 1, the difference is that when preparing the matching layer, the mass ratio of cement, epoxy resin and tungsten powder is 1:1:3, and the mass ratio of curing agent to epoxy resin The ratio is 4:1.

[0079] Performance tests were performed on the obtained sensor, and its orthotropic characteristics, sensitivity, bandwidth and other performances were similar to those of the sensor in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com