A flow battery shutdown protection method and a flow battery system

A flow battery, shutdown protection technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as high load life performance and life requirements, affecting stack life, not experiencing dynamic operation, etc., to achieve battery life. The effect of long time, low investment and slow capacity decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

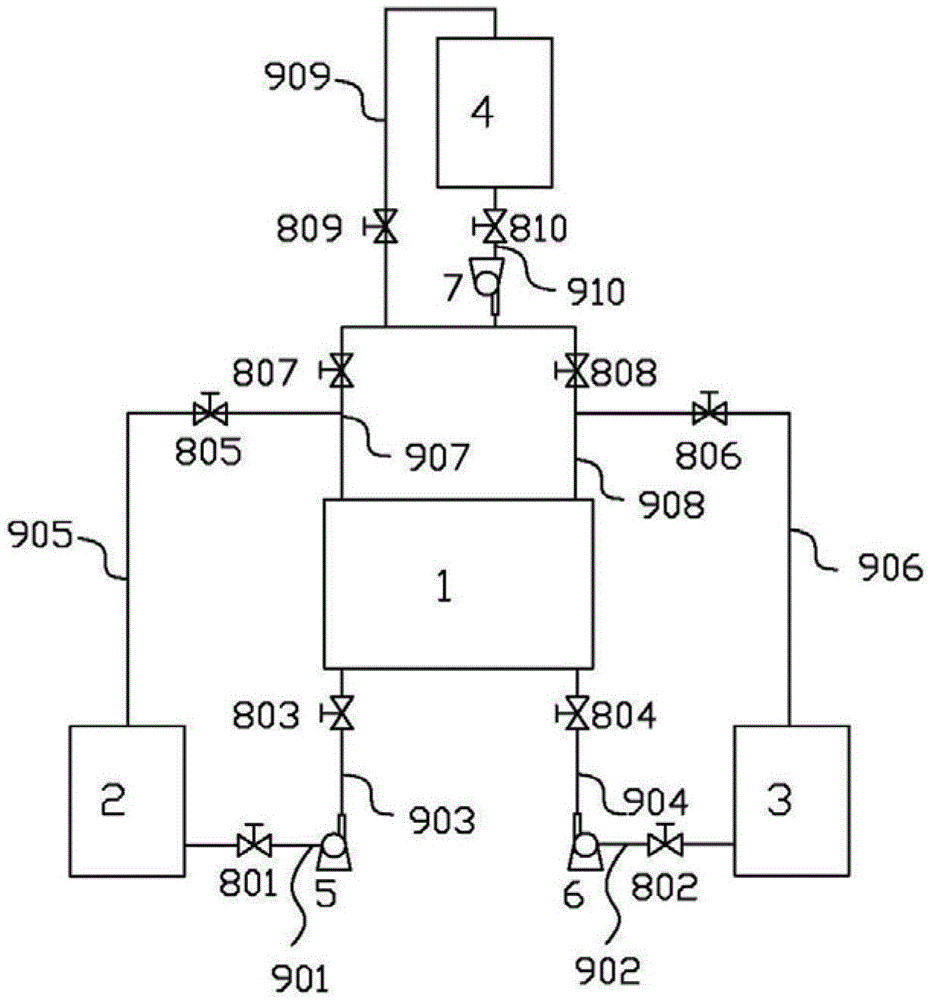

[0028] A liquid flow battery system, the battery system includes a stack 1, a positive electrolyte storage tank 2, a negative electrolyte storage tank 3, a positive electrolyte delivery pump 5, a negative electrolyte delivery pump 6, a mixed solution storage tank 4 and Mixed solution delivery pump 7.

[0029] The stack 1 is connected to the positive electrode electrolyte delivery pump 5 and the negative electrode electrolyte delivery pump 6 respectively through the pipeline III903 and the pipeline IV904, and the valve III803 and the valve IV804 are respectively set on the pipeline III903 and the pipeline IV904; the positive electrode electrolyte delivery pump 5 and the negative electrode electrolytic The liquid delivery pump 6 is connected to the positive electrode electrolyte storage tank 2 and the negative electrode electrolyte storage tank 3 through the pipeline I901 and the pipeline II902 respectively. The positive electrode electrolyte storage tank 2 and the negative elec...

Embodiment 2

[0033] Device and mode of operation are the same as embodiment 1

[0034] When the battery power is 10kw, the solution in the battery is 100L, the SOC state is 30%, the voltage across the battery is 47V, and 30L of solution is stored in the mixed solution storage tank 4 . The voltage disappears after discharge.

Embodiment 3

[0036] Device and mode of operation are the same as embodiment 1

[0037] After the stack is assembled into a battery system with a success rate of 100kw, the solution in the storage tank in the battery system is 1000L at this time. When the SOC state of the battery system is 50%, the voltage at both ends of the battery is 320V. At this time, it needs to be stored in the storage tank 4 500L solution. After the battery system was discharged, the voltage disappeared after injecting 500L of mixed solution into the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com