A bidirectional rotating ultrasonic motor driven by a single electrical signal

A bidirectional rotating, ultrasonic motor technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Torque and speed stability, complex structure of rotating ultrasonic motor, etc., to achieve the effect of light weight, low assembly difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

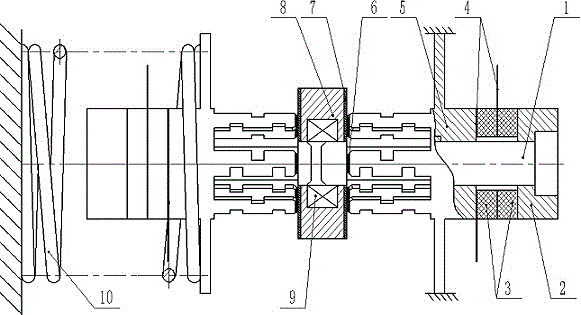

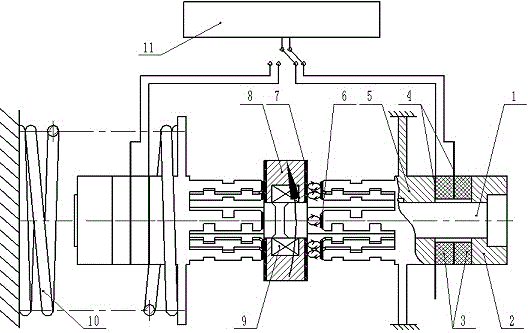

[0020] combine figure 1 , 2 As shown, a single electric signal driven bidirectional rotary ultrasonic motor of the present invention includes two identical stators, a rotor and a set of positive pressure preload adjustment mechanism. The cover plate, piezoelectric ceramic sheet, electrode sheet, elliptical vibration mode converter, the mandrel and the elliptical vibration mode converter are connected by threads, and then the rear cover plate, piezoelectric ceramic sheet, electrode sheet and elliptical vibration mode converter are connected Pressing and fixing, the rear cover 2 and the mandrel 1 are of a split structure.

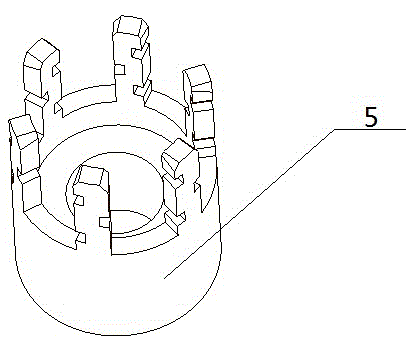

[0021] The elliptical vibration mode converter 5 is an integrated structure, including a lower cylindrical part and an upper driving tooth part, and the driving tooth part is uniformly arranged on the upper end of the cylindrical part in the circumferential direction, and each driving tooth It is a strip structure with three misaligned rectangular notches o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com