Device and method for drive control of servo direct current motor

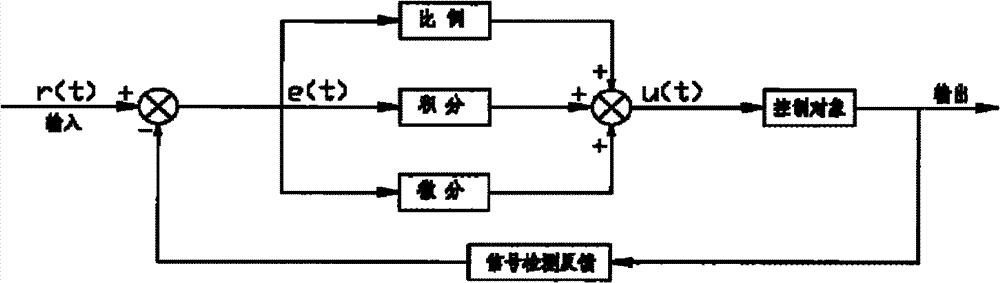

A technology of DC motor and control method, applied in the direction of speed/torque control of a single motor, can solve problems such as poor control performance and inability to meet the high precision requirements of servo drives, achieve low cost, increase safety factor, and reduce control effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

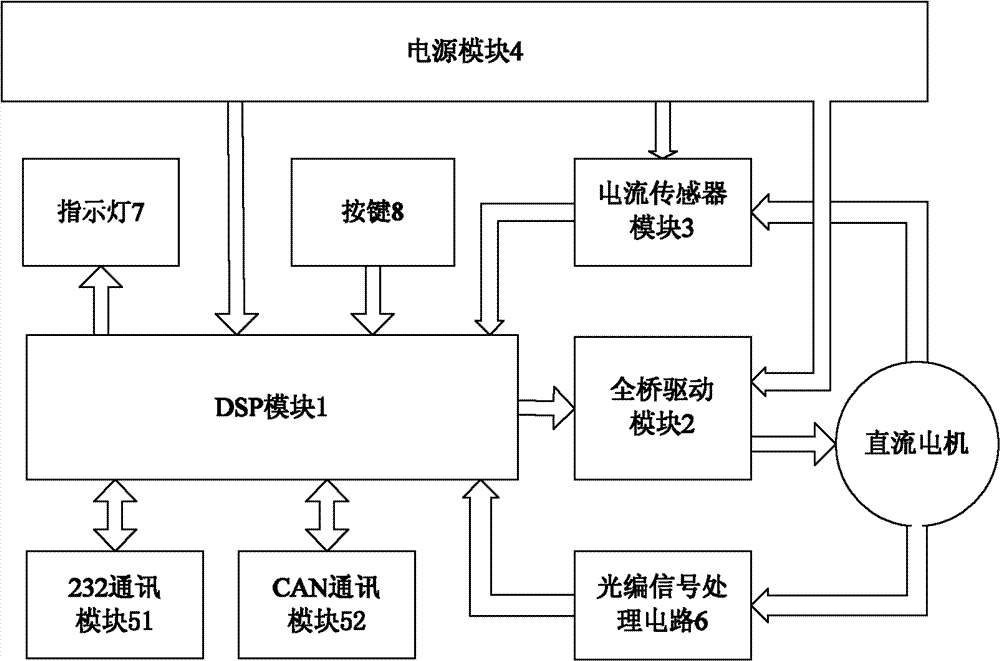

[0035] refer to figure 2 As shown, the present invention discloses a servo DC motor drive control device, which includes: DSP module 1, full bridge drive module 2, current sensor module 3, power supply module 4, communication module, optical encoder signal processing circuit 6, indicator light 7 and button 8, where:

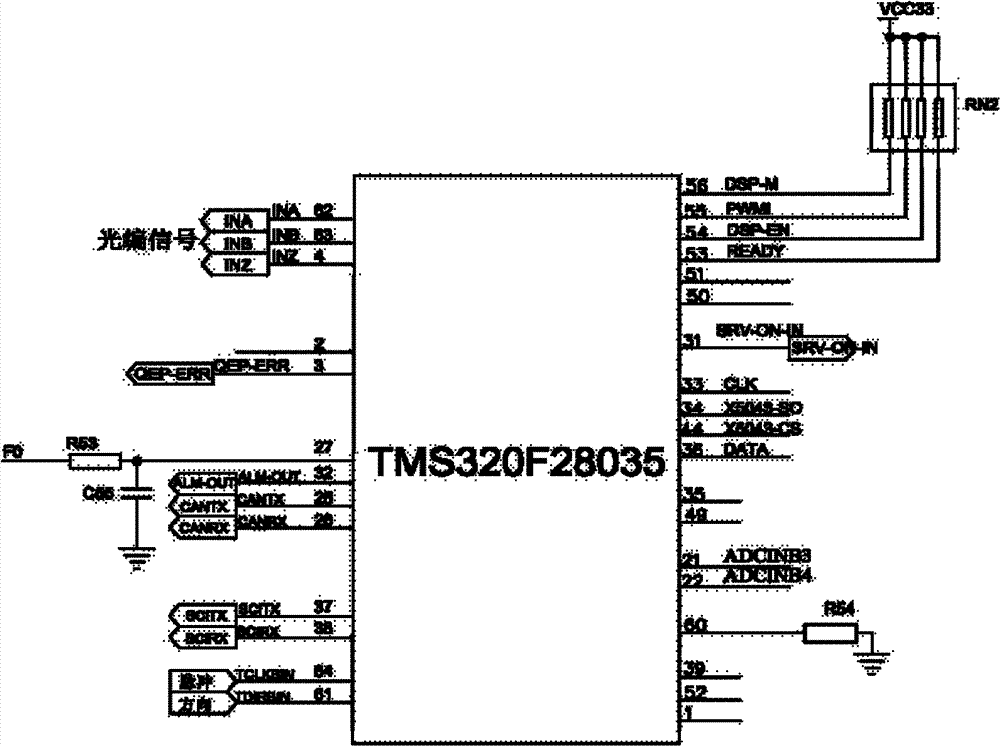

[0036] DSP module 1 is designed with the latest 32-bit Piccolo series TMS320F28035 from TI. This DSP is small in size, with a maximum frequency of 60MHz, 64K Flash, 14 channels of 12-bit AD, 12 channels of PWM, 1 Group QEP, 1 group CAP, 33 general-purpose IO, SPI, SCI, and CAN inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com