Light-emitting diode (LED) drive power supply and adhesive pouring method thereof

A LED drive and power supply technology, applied in the field of power supply, can solve the problems of poor sealing performance of the drive power supply and high product defect rate, and achieve the effects of reducing material consumption, excellent waterproof performance, and preventing violent disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

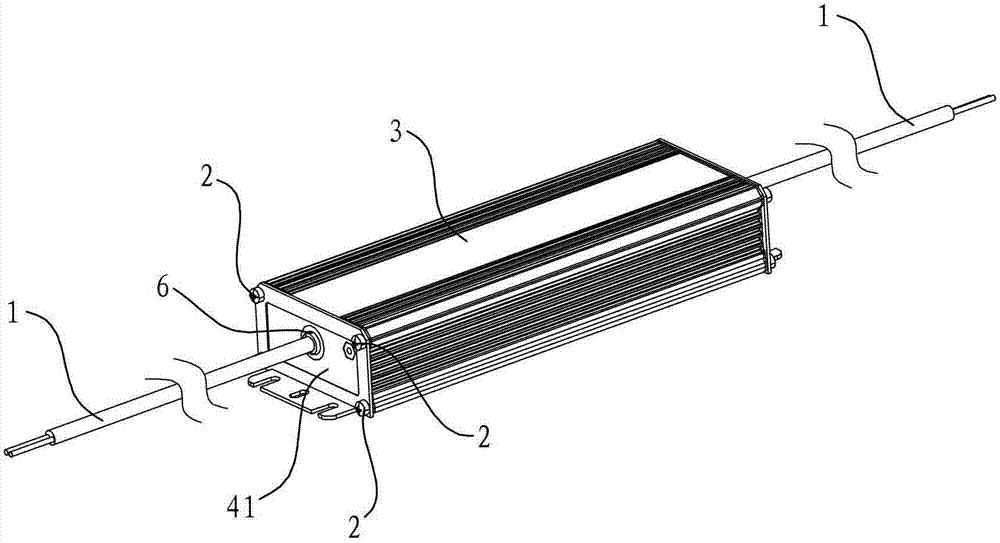

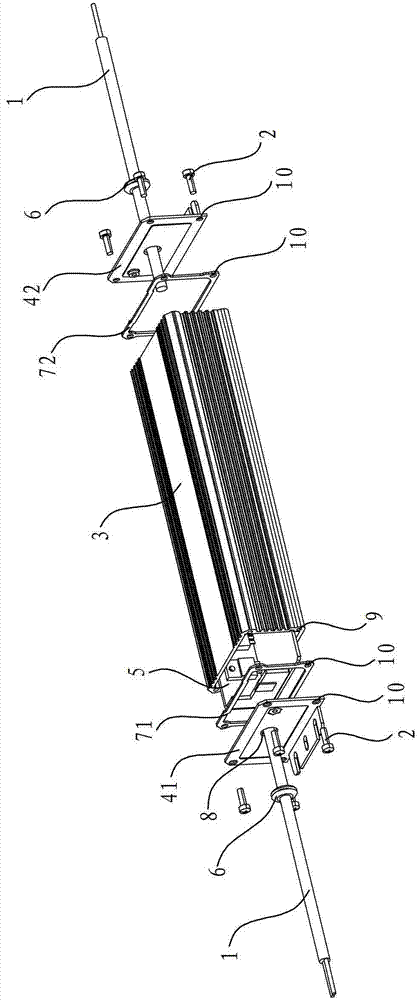

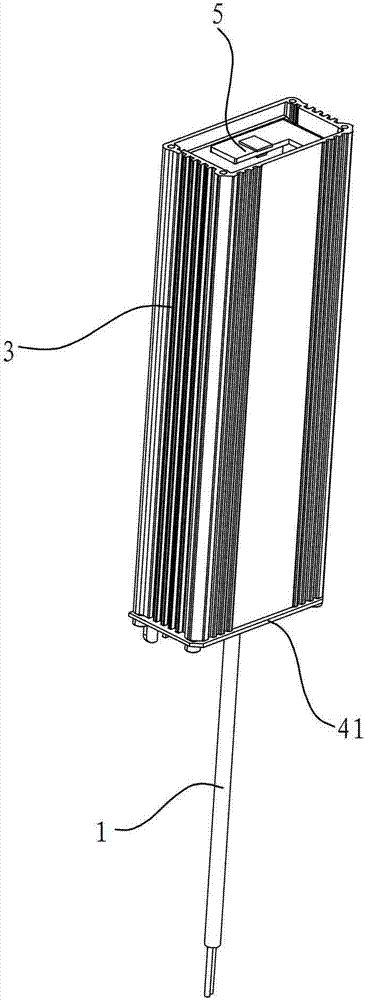

[0026] Such as Figure 1 to Figure 3 As shown, the LED driving power supply in this embodiment includes a rectangular parallelepiped box-shaped casing 3, and a PCBA assembly 5 is arranged inside the casing 3, and both ends of the casing 3, that is, the first end and the second end of the casing 3 are formed Opening, and the first end cover 41 is installed at the opening of one end of the housing 3, and the first end cover 41 and the housing 3 are sealed by the first gasket 71; the opening of the other end of the housing 3 is installed with the second The end cover 42 , and the second end cover 42 and the casing 3 are sealed by the second gasket 72 . A threading hole 8 is opened at the center of the first end cover 41 and the second end cover 42 , and the wire 1 passes through the threading hole 8 from the inside of the housing 3 to the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com