Fischer-Tropsch synthesis catalyst, its preparation and application

A Fischer-Tropsch synthesis and catalyst technology, which is applied in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high selectivity and low activity of methane, Achieve the effect of high activity and selectivity, high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

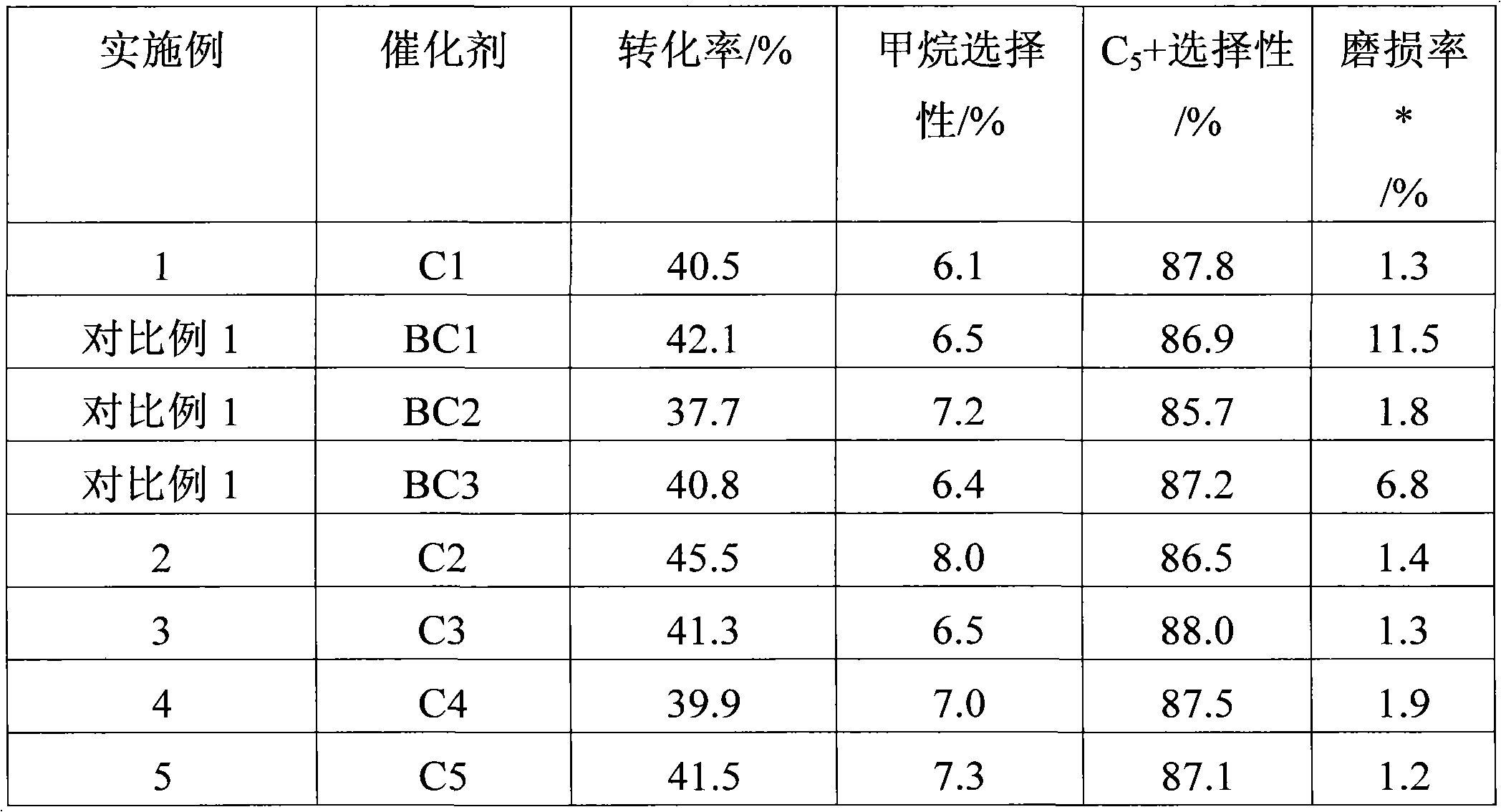

Examples

Embodiment 1

[0066] This example illustrates the catalyst provided by the present invention, its preparation and its performance.

[0067] (1) Silicon and divalent metal component surface modification carrier and its preparation

[0068] Add 14.8 g of ethyl orthosilicate to 150 mL of cyclohexane, and dissolve to obtain a Si solution. With 100g gamma-alumina (Sasol product, average particle diameter 55 microns, specific surface area 150 meters 2 / g, pore volume 0.45 ml / g) was added to the above solution and stirred continuously for 1h. After filtering, the filter cake was dried in an oven at 140° C. for 6 hours.

[0069] Add 15.62g of zinc nitrate hexahydrate into 100mL of water, and dissolve to obtain a Zn solution. Add 100 g of the above Si-modified alumina into the Zn solution and stir continuously for 1 h, then filter, put the filter cake in an oven at 140° C. for 6 hours, and bake at 600° C. for 2 h. A silicon- and zinc-modified alumina support was obtained, calculated as elements ...

Embodiment 2

[0098] This example illustrates the catalyst, preparation and performance of the catalyst supported by silicon and cobalt surface-modified alumina.

[0099] (1) Carrier and its preparation

[0100] Add 9.9 g of ethyl orthosilicate to 150 mL of cyclohexane, and dissolve to obtain a Si solution. 100g gamma-alumina (Sasol product, average particle size 55 microns, specific surface area 150 m 2 / g, pore volume 0.45 ml / g) was added to the above solution and stirred continuously for 1h. After filtering, the filter cake was dried in an oven at 180° C. for 1 hour.

[0101] Add 15.28 g of cobalt nitrate hexahydrate into 100 mL of water, and dissolve to obtain a Co solution. Add 100 g of the above-mentioned Si-modified alumina into the Co solution and stir continuously for 1 h, then filter, put the filter cake in an oven at 180° C. for 2 hours, and bake at 800° C. for 2 h. A silica- and cobalt-modified alumina support is obtained, calculated as elements and based on the support, the...

Embodiment 3

[0107]This example illustrates the catalyst, preparation and performance of the catalyst with silicon and Ni surface-modified alumina as the carrier.

[0108] (1) Carrier and its preparation

[0109] Add 19.8 g of ethyl orthosilicate to 150 mL of cyclohexane, and dissolve to obtain a Si solution. 100g gamma-alumina (Sasol product, average particle size 55 microns, specific surface area 150 m 2 / g, pore volume 0.45 ml / g) was added to the above solution and stirred continuously for 1h. After filtering, the filter cake was dried in an oven at 180° C. for 1 hour.

[0110] Add 15.27 g of nickel nitrate hexahydrate into 100 mL of water, and dissolve to obtain a Ni solution. Add 100 g of the above-mentioned Si-modified alumina to the Ni solution and stir continuously for 1 h, then filter, put the filter cake in an oven at 160° C. for 2 hours, and bake at 700° C. for 2 h. A silicon and nickel-modified alumina support was obtained. In terms of elements and based on the support, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com