A kind of preparation method of cast copper squirrel cage rotor

A squirrel-cage rotor and copper casting technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of broken bars, easy oxidation, poor fluidity, and easy existence of air bubbles in rotor guide bars, and achieve detachment The effect of convenient mold, high production efficiency and fast casting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

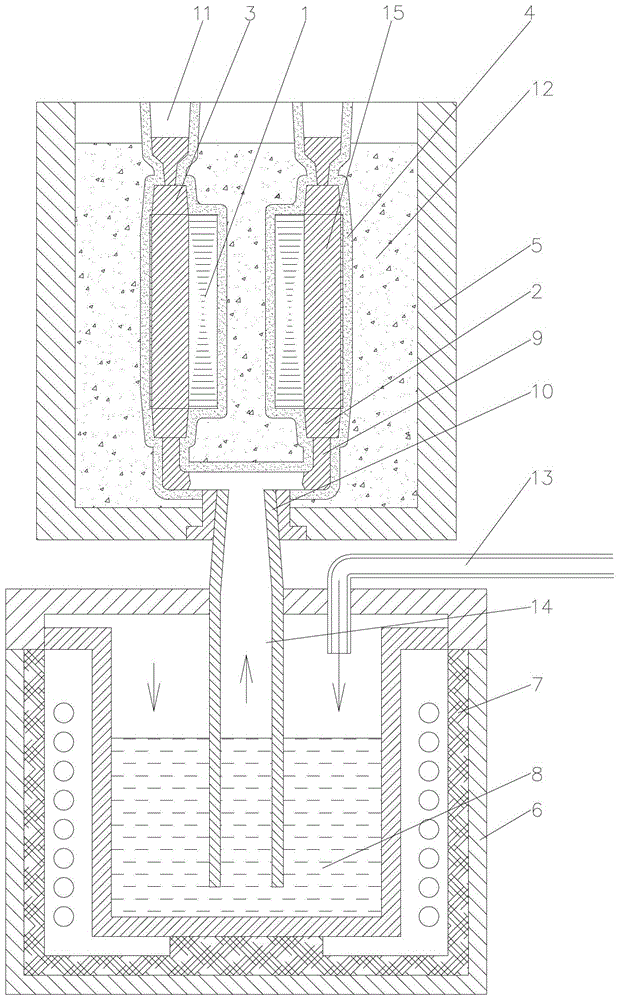

[0023] Such as figure 1 As shown, the technical solution of the present invention is: a method for preparing a cast copper squirrel cage rotor. The preparation method first adopts the lost wax investment process to prepare the pouring cavity, and then places the pouring cavity on a low-pressure casting machine for rapid casting molding, which includes the following steps:

[0024] 1) First coat a layer of high temperature resistant insulating coating on the rotor core 1;

[0025] 2) Then set the rubber casting wax mold of the squirrel cage rotor on the rotor core 1 processed in step 1), and cast a wax pattern with the same shape as the preset squirrel cage rotor; after removing the wax casting mold, the wax pattern The gate wax pattern made of wax in advance is welded at the end ring on the lower side, and the riser (and exhaust port) wax pattern made of wax in advance is welded at the end ring on the upper side of the wax pattern at 3;

[0026] 3) Make a sand mold shell 4 o...

Embodiment 1

[0031] A method for preparing a cast copper squirrel cage rotor. The preparation method first adopts a lost-wax investment process to prepare a pouring cavity, and then places the pouring cavity on a low-pressure casting machine for rapid casting. It includes the following steps:

[0032] 1) First coat a layer of high temperature resistant insulating coating made of water glass on the rotor core 1;

[0033] 2) Then set the rubber casting wax mold of the squirrel cage rotor on the rotor core 1 processed in step 1), and cast a wax pattern with the same shape as the preset squirrel cage rotor; after removing the wax casting mold, the wax pattern The gate wax pattern made of wax in advance is welded at the end ring place 2 on the lower side, and the riser wax pattern made with wax in advance is welded at the end ring place 3 on the wax pattern upper side;

[0034] 3) Make a sand mold shell 4 with quartz sand and water glass as raw materials outside the rotor core 1 and the wax pat...

Embodiment 2

[0039] A method for preparing a cast copper squirrel cage rotor. The preparation method first adopts a lost-wax investment process to prepare a pouring cavity, and then places the pouring cavity on a low-pressure casting machine for rapid casting. It includes the following steps:

[0040]1) First coat a layer of high temperature resistant insulating coating made of fine ceramic powder on the rotor core 1;

[0041] 2) Then set the rubber casting wax mold of the squirrel cage rotor on the rotor core 1 processed in step 1), and cast a wax pattern with the same shape as the preset squirrel cage rotor; after removing the wax casting mold, the wax pattern The gate wax pattern made of wax in advance is welded at the end ring place 2 on the lower side, and the riser wax pattern made with wax in advance is welded at the end ring place 3 on the wax pattern upper side;

[0042] 3) Make sand mold shell 4 with resin sand as raw material outside the rotor core 1 and the wax pattern, and inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com