Processing method for crankshaft of compressor

A processing method and crankshaft technology are applied in the field of crankshafts, which can solve the problems of increased eccentricity of the crankshaft and insufficient torque transmission capacity, and achieve the effects of improving air tightness and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

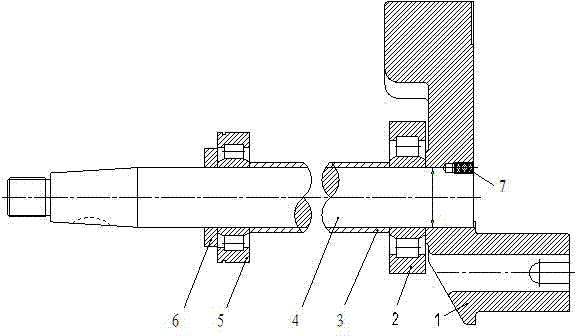

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail:

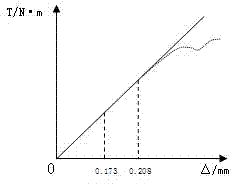

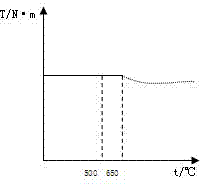

[0022] The structure of crankshaft of the present invention is as figure 1 As shown, it includes a crank 1 and a crankshaft 4, wherein the crank 1 and the crankshaft 4 are interference fit. The specific processing steps are: first, design the outer diameter of the crankshaft as Φ55, the deviation is (+0.018 +0.008), the design size of the crank aperture is Φ55, the deviation is (-0.165 -0.190), and the interference is △min =0.173, △max=0.208; then the aperture of the crank is heated to 500-600°C by induction heating, preferably in the range of 540-550°C. In this embodiment, the heating temperature is 550°C. The crank hole is increased by 0.1-0.2mm after heating, and the crankshaft can be easily inserted into the crank hole vertically as required in this case, and finally cooled and shaped.

[0023] In the present invention, after the crankshaft and crank are assembled by me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com