Reversible thermochromic material and application thereof

A color-changing material and heat-sensitive technology, applied in color-changing fluorescent materials, applications, household appliances, etc., can solve the problems of high color-changing range, short service life, and high price, and achieve clear high-temperature areas, simple temperature measurement, and high cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

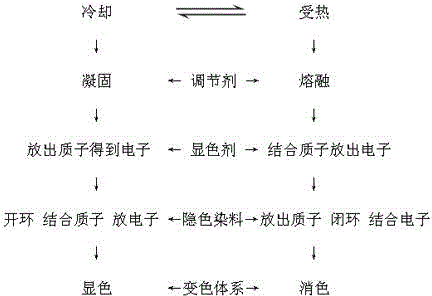

Method used

Image

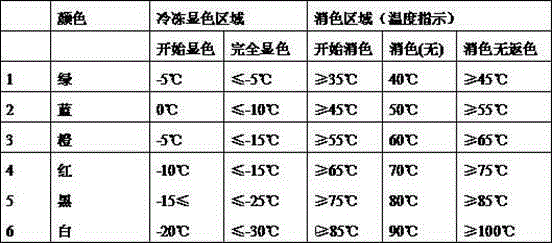

Examples

Embodiment 1

[0031] 1. Prepare the heat-sensitive reversible color material according to the above formula, and dry it into powder.

[0032] 2. Preparation of heat-sensitive reversible color water-based ink.

[0033] Take 15% heat-sensitive reversible color material powder, 30% water-based acrylic resin, 1% surfactant Tween 61, 10% polyol, 0.5% anti-ultraviolet agent Tinuvin 1130, 0.2 % Bactericidal preservative G1, 0.1% defoamer DF-58, and 0.01% pH adjustment stabilizer AMP-95, the balance is deionized water, stir and disperse at room temperature to mix evenly, and then filter through 100 stainless steel The heat-sensitive reversible color water-based ink is obtained by sieve filtration. During the preparation process, it cannot be heated to the temperature at which the color disappears, and the pH needs to be strictly controlled between 6.0 and 7.0.

[0034] The heat-sensitive reversible water-based ink was frozen at -25°C for 48 hours.

[0035] 3. Prepare thermal and reversible color temperat...

Embodiment 2

[0038] 1. Prepare heat-sensitive reversible color material color paste, and freeze the color paste at -25°C for 24 hours and then thaw it for use.

[0039] 2. Preparation of thermal reversible color water-based ink.

[0040] Take 40% by weight of thawed thermal reversible color material slurry, 20% water-based acrylic resin, 3% surfactant Span 80, 15% polyol, 1% anti-ultraviolet agent Tinuvin 292, 0.4% germicidal preservative G2, 0.2% defoamer Defom W-090, and 0.05% pH adjustment stabilizer AMP-95, the balance is deionized water, stir and disperse and mix well at room temperature, then The heat-sensitive reversible color water-based ink is filtered through 100 stainless steel filter sieve. During the preparation process, it cannot be heated to the temperature at which the color disappears, and the pH needs to be strictly controlled between 6.0 and 7.0.

[0041] 3. Prepare thermal and reversible color temperature indicator stickers.

[0042] The heat-sensitive reversible color water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com