Photochromic film material and preparation method thereof

A thin-film material and photochromic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, coatings, etc., can solve the problems of not being able to indicate the results of continuous cumulative irradiation of ultraviolet rays, and achieve low cost, easy promotion and application, and skin protection prevent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

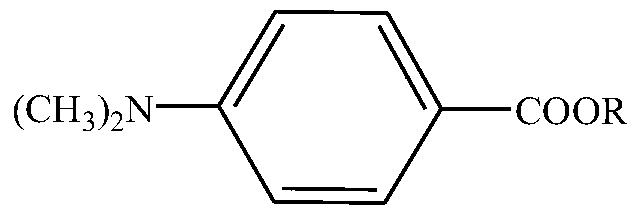

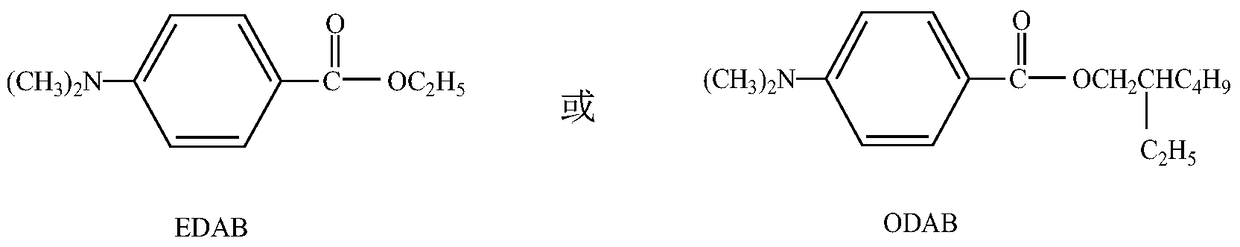

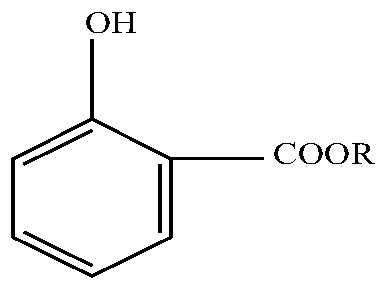

[0030] 1. Proportioning components according to mass percentage:

[0031]

[0032] 2. Preparation method:

[0033] Weigh 10g of EDAB, 5g of methyl salicylate, 2.5g of benzotriazole, 25g of silicone resin, 5g of phosphomolybdic acid, mix in a mixer for 0.5h, the stirring speed is 300r / min, mix well and add isocyanate group 2.5 g of the silane coupling agent was stirred at a speed of 300 r / min for 0.5 h, and the obtained composition was ink-jet printed on a polyurethane film, and cured at room temperature at 25° C. to obtain a film material.

[0034] Three, the effect of this embodiment:

[0035] After testing, the mechanical hardness is 2H, the flexibility is ≤1mm, and the color difference does not change significantly after 72 hours under sunlight.

Embodiment 2

[0037] 1. Proportioning components according to mass percentage:

[0038]

[0039] 2. Preparation method:

[0040] Weigh 25g of ODAB, 7.5g of phenyl salicylate, 2.25g of benzotriazole, 2.5g of silicone resin, and 12.5g of phosphomolybdic acid, and mix them in a mixer for 0.5h at a stirring speed of 300r / min. Add 0.25 g of isocyanate silane coupling agent, continue to stir at 300 r / min for 0.5 h, screen-print the obtained composition on a polyurethane film, and cure at 125° C. to obtain a film material.

[0041] Three, the effect of this embodiment:

[0042] After testing, the mechanical hardness is 2H, the flexibility is ≤1mm, the color difference reaches the maximum in 24 hours under sunlight, the indication is not obvious in the dark, and the experimental effect is not good.

Embodiment 3

[0044] 1. Proportioning components according to mass percentage:

[0045]

[0046] 2. Preparation method:

[0047] Weigh 15g of ODAB, 2.25g of methyl salicylate, 0.5g of benzotriazole, 22.5g of silicone resin, 7.5g of phosphomolybdic acid, and mix them in a mixer for 0.5h at a stirring speed of 300r / min. Add 2.25 g of isocyanatosilane coupling agent, continue to stir at 300 r / min for 0.5 h, screen-print the obtained composition on a polyurethane film, and cure at 100° C. to obtain a film material.

[0048] Three, the effect of this embodiment:

[0049] After testing, the mechanical hardness is 2H, the flexibility is ≤2mm, the color difference is obvious after 72 hours under sunlight, and the continuity of the change is not good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com