Supporting structure with combination of preheated groove-shaped piles and mixing piles

A technology of supporting structure and stirring pile, which is applied in the direction of foundation structure engineering, sheet pile wall, excavation, etc., can solve problems such as poor combination between stirring pile and supporting pile, complicated manufacturing process of I-shaped pile, and difficulty in avoiding soil leakage. , to achieve the effect of low cost, simple manufacturing process and fast manufacturing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

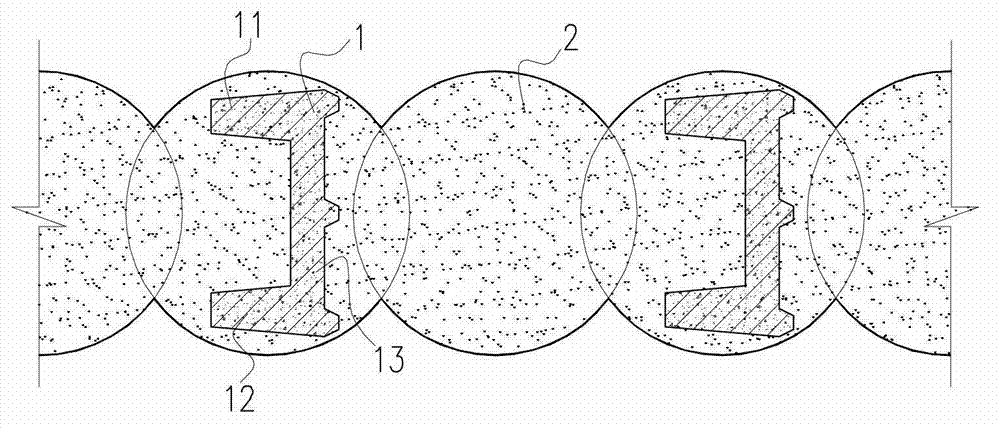

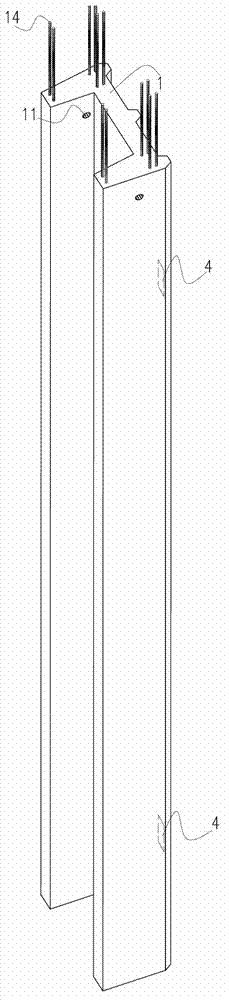

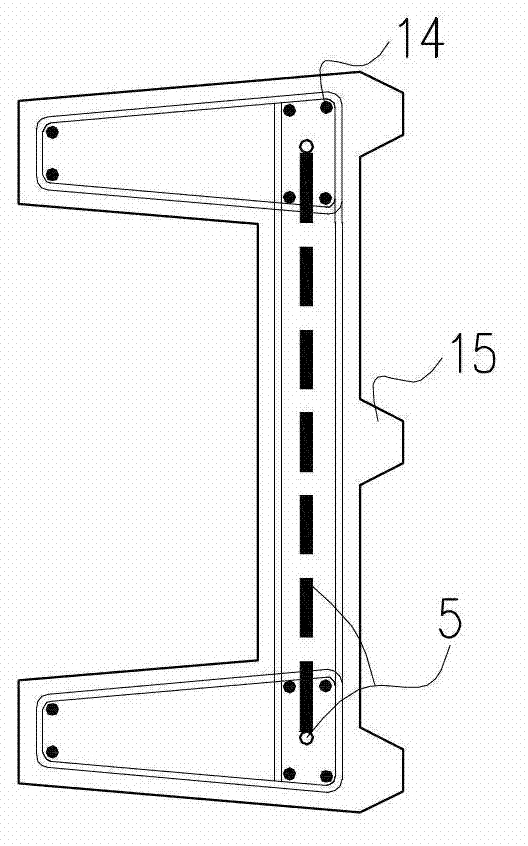

[0017] see Figure 1 to Figure 4 , a support structure combining prefabricated grooved piles and stirring piles provided by the present invention includes prefabricated grooved piles 1 and stirring piles 2, and the prefabricated grooved piles 1 are composed of an upper flange 11 and a lower flange 12 The channel section combined with the web 13, the upper flange 11 and the lower flange 12 have variable thickness, the thickness near the web end is greater than the outer end thickness, and the upper flange 11 and the lower flange 12 are longitudinally embedded with prestressed Steel strands 14, and at least every other stirring pile 2 of the prefabricated trough pile 1 is inserted into the stirring pile 2, and the stirring piles 2 are overlapped and arranged. Channel piles can be easily manufactured by tire mold long-line method, which has high work efficiency and low manufacturing cost. The variable thickness of the flange is used to facilitate mold removal, but it will not aff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com