Manual and automatic control system for realizing single-action control through pneumatic double-action executing mechanism with gas storage tank

An automatic control system and actuator technology, which is applied to the safety of fluid pressure actuation systems, components of fluid pressure actuation systems, and mechanical equipment. Easy operation, simple control, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

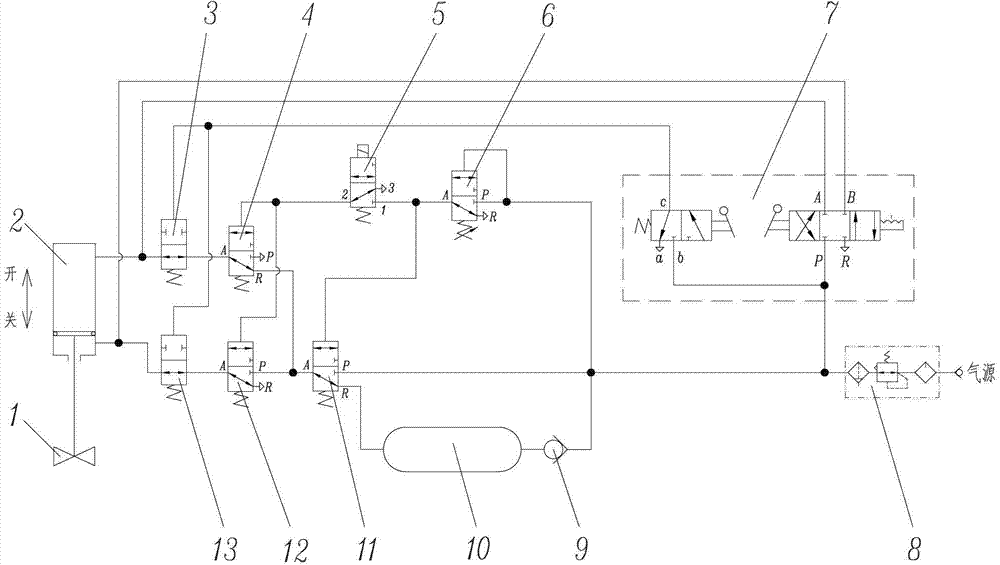

Embodiment 1

[0023] refer to figure 1, the pneumatic double-acting control valve of the present invention realizes the F.C manual automatic control system, including a valve 1, a pneumatic double-acting actuator 2, a first air control valve 3, a second air control valve 4, a solenoid valve 5, and a pressure switch 6 (for possible adjustable pressure switch), on-site manual control panel 7, air filter decompression assembly 8, one-way valve 9, air storage tank 10, third air control valve 11, fourth air control valve 12, fifth air control valve 13. The valve 1 and the pneumatic double-acting actuator 2 form a pneumatic control valve, the first air control valve 3, the second air control valve 4, the solenoid valve 5, the pressure switch 6, the on-site manual control panel 7, the air filter decompression Assembly 8, one-way valve 9, gas storage tank 10, third air control valve 11, fourth air control valve 12, fifth air control valve 13, and several air pipelines and ferrule joints form a manu...

Embodiment 2

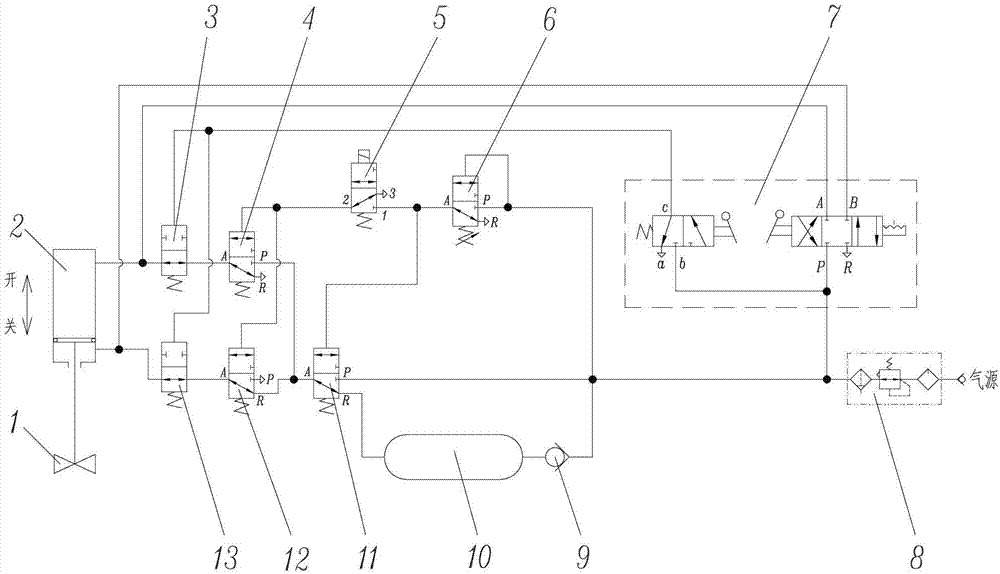

[0026] refer to figure 2 , the pneumatic double-acting control valve of the present invention realizes the F.O manual automatic control system, including a valve 1, a pneumatic double-acting actuator 2, a first air control valve 3, a second air control valve 4, a solenoid valve 5, and a pressure switch 6 (for possible adjustable pressure switch), on-site manual control panel 7, air filter decompression assembly 8, one-way valve 9, air storage tank 10, third air control valve 11, fourth air control valve 12, fifth air control valve 13. its connection with figure 1 Similarly, the difference is that the normally closed port P of the second air control valve 4 is connected to the branch of the three-way ferrule joint between the fourth air control valve 12 and the third air control valve 11, and the normally open port P of the second air control valve 4 Port R is equipped with a silencer and communicates with the atmosphere. The normally open port R of the fourth air control va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com