Covering materials for insulating substrates

A technology of insulating substrates and coating materials, which is applied in welding/cutting media/materials, applications, household appliances, etc., and can solve problems such as inability to achieve semiconductor component installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

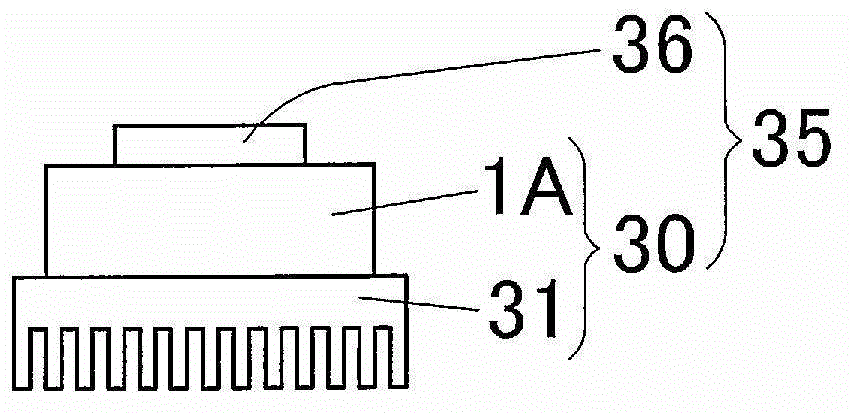

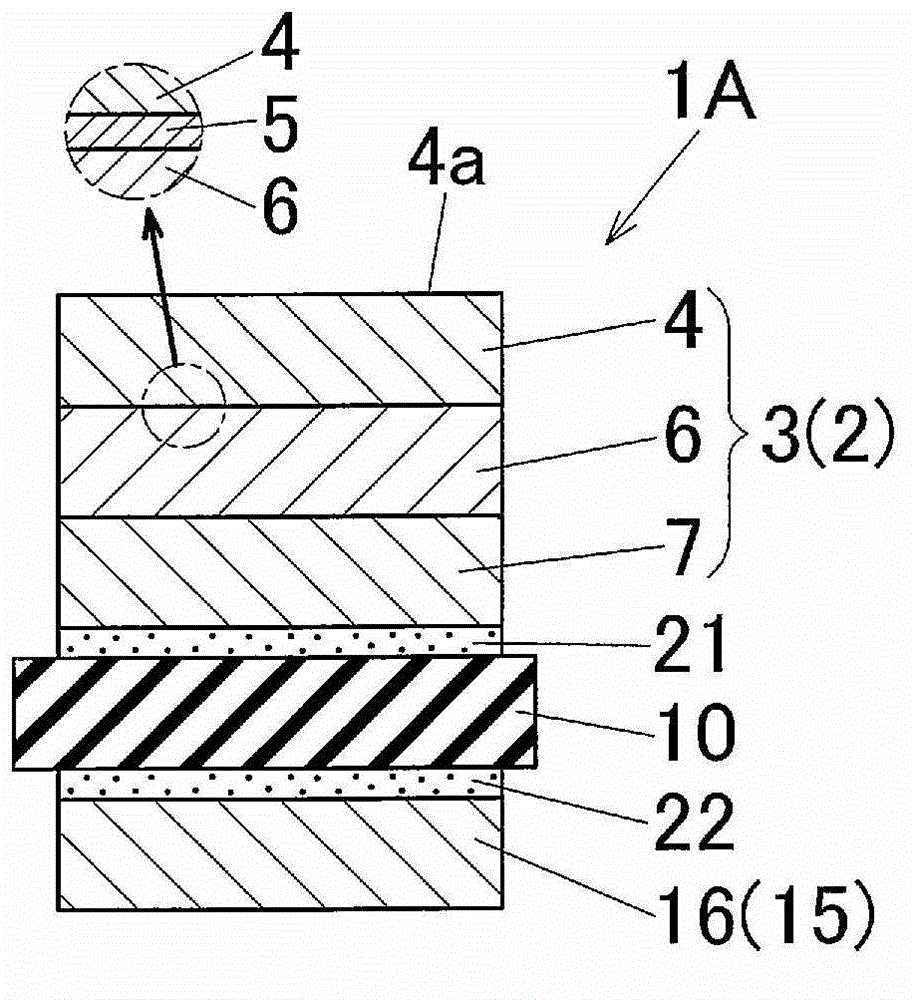

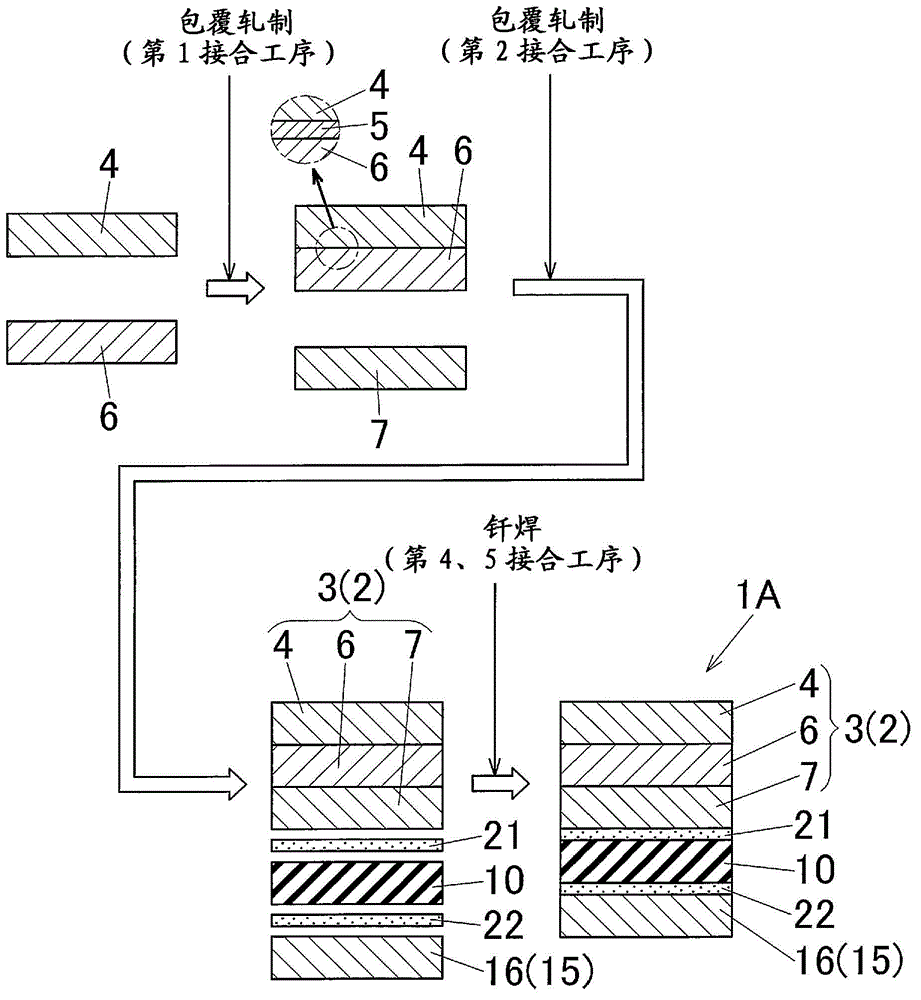

[0198] In this Example 1, a figure 2 and the insulating substrate 1A of the above-mentioned first embodiment shown in 3. Its production method is as follows.

[0199] The lower plate is prepared as the Ni layer 4, the Ti layer 6, the first Al layer 7, the ceramic layer 10, and the third Al layer 16, respectively.

[0200] Ni layer 4: a pure Ni plate with a length of 25 mm x a width of 25 mm x a thickness of 50 μm

[0201] Ti layer 6: a pure Ti plate with a length of 25 mm x a width of 25 mm x a thickness of 200 μm

[0202] The first Al layer 7: a pure Al plate with a length of 25 mm x a width of 25 mm x a thickness of 600 μm

[0203] Ceramic layer 10: AlN plate of 25 mm in length x 25 mm in width x 600 μm in thickness

[0204] The third Al layer 16: a pure Al plate with a length of 25 mm x a width of 25 mm x a thickness of 600 μm.

[0205] The purity of the Ni plate forming the Ni layer 4 is JIS (Japanese Industrial Standard) Class 1. The purity of the Ti plate forming ...

Embodiment 2

[0211] In this Example 2, a Figure 5 The insulating substrate 1B of the above-mentioned second embodiment is shown. Its production method is as follows.

[0212] Lower plates were prepared as Ni layer 4 , Ti layer 6 , first Al layer 7 , second Al layer 8 , ceramic layer 10 , and third Al layer 16 .

[0213] Ni layer 4: a pure Ni plate with a length of 25 mm x a width of 25 mm x a thickness of 20 μm

[0214] Ti layer 6: a pure Ti plate with a length of 25 mm x a width of 25 mm x a thickness of 20 μm

[0215] The first Al layer 7: a pure Al plate with a length of 25 mm x a width of 25 mm x a thickness of 40 μm

[0216] The second Al layer 8: a pure Al plate with a length of 25 mm x a width of 25 mm x a thickness of 600 μm

[0217] Ceramic layer 10: AlN plate of 25 mm in length x 25 mm in width x 600 μm in thickness

[0218] The third Al layer 16: a pure Al plate with a length of 25 mm x a width of 25 mm x a thickness of 600 μm.

[0219] The purity of the Ni plate forming ...

Embodiment 3

[0225] In this Example 3, the same method as in Example 2 above was produced Figure 5 The insulating substrate 1B of the above-mentioned second embodiment is shown. Its production method is as follows.

[0226] Lower plates were prepared as Ni layer 4 , Ti layer 6 , first Al layer 7 , second Al layer 8 , ceramic layer 10 , and third Al layer 16 .

[0227] Ni layer 4: a pure Ni plate with a length of 25 mm x a width of 25 mm x a thickness of 15 μm

[0228] Ti layer 6: a pure Ti plate with a length of 25 mm x a width of 25 mm x a thickness of 15 μm

[0229] The first Al layer 7: an Al plate with a length of 25 mm x a width of 25 mm x a thickness of 100 μm

[0230] The second Al layer 8: a pure Al plate with a length of 25 mm x a width of 25 mm x a thickness of 600 μm

[0231] Ceramic layer 10: AlN plate of 25 mm in length x 25 mm in width x 600 μm in thickness

[0232] The third Al layer 16: a pure Al plate with a length of 25 mm x a width of 25 mm x a thickness of 600 μm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com