Small multipurpose unmanned plane with oil tank embedded into blended wing body

A technology of small unmanned aerial vehicles and fuel tanks, which is applied to the fuel tank of the power unit, the shape of the wing, and the direction of automatic control, which can solve the problems of small fuel volume, not very convenient, and low space utilization in the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

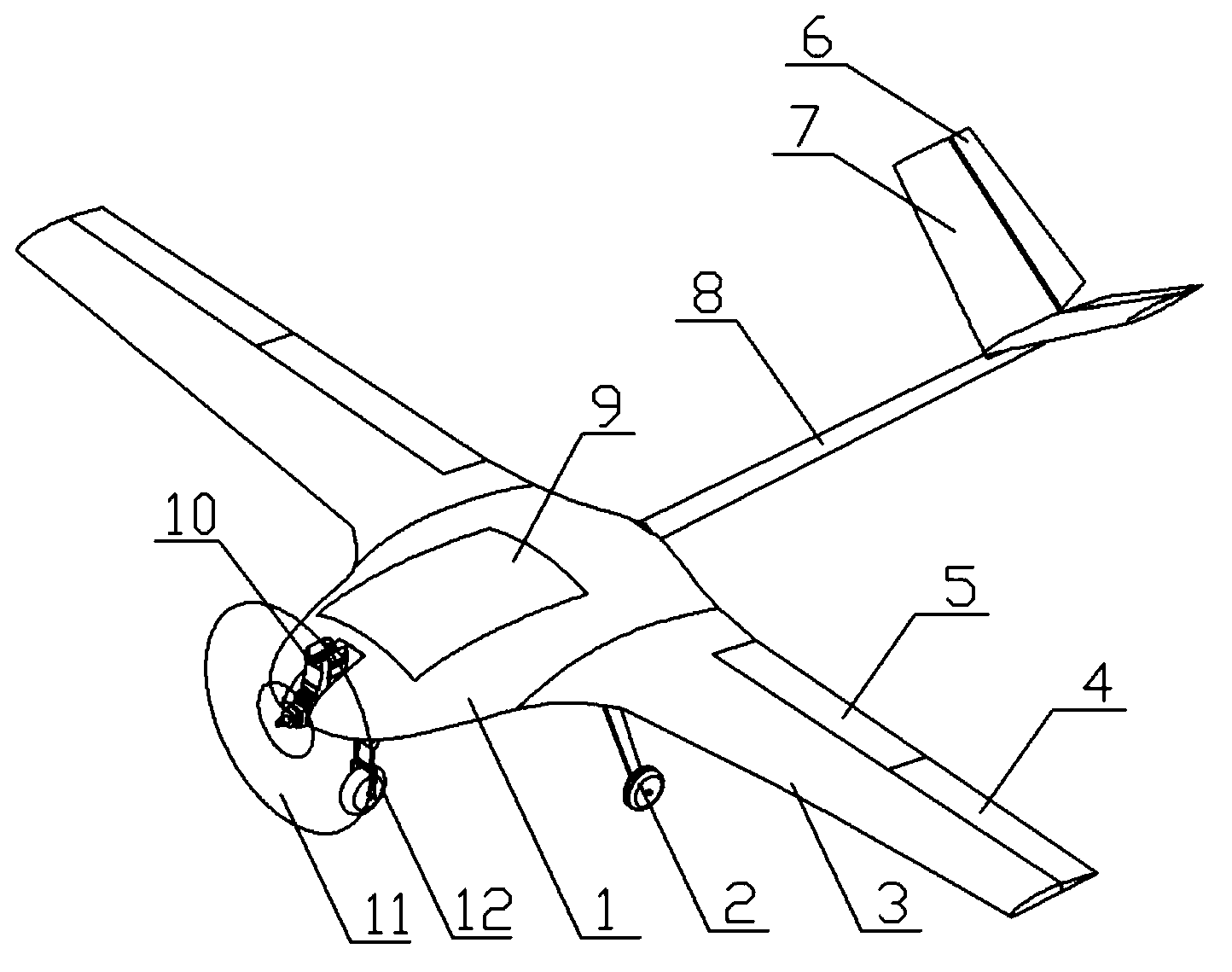

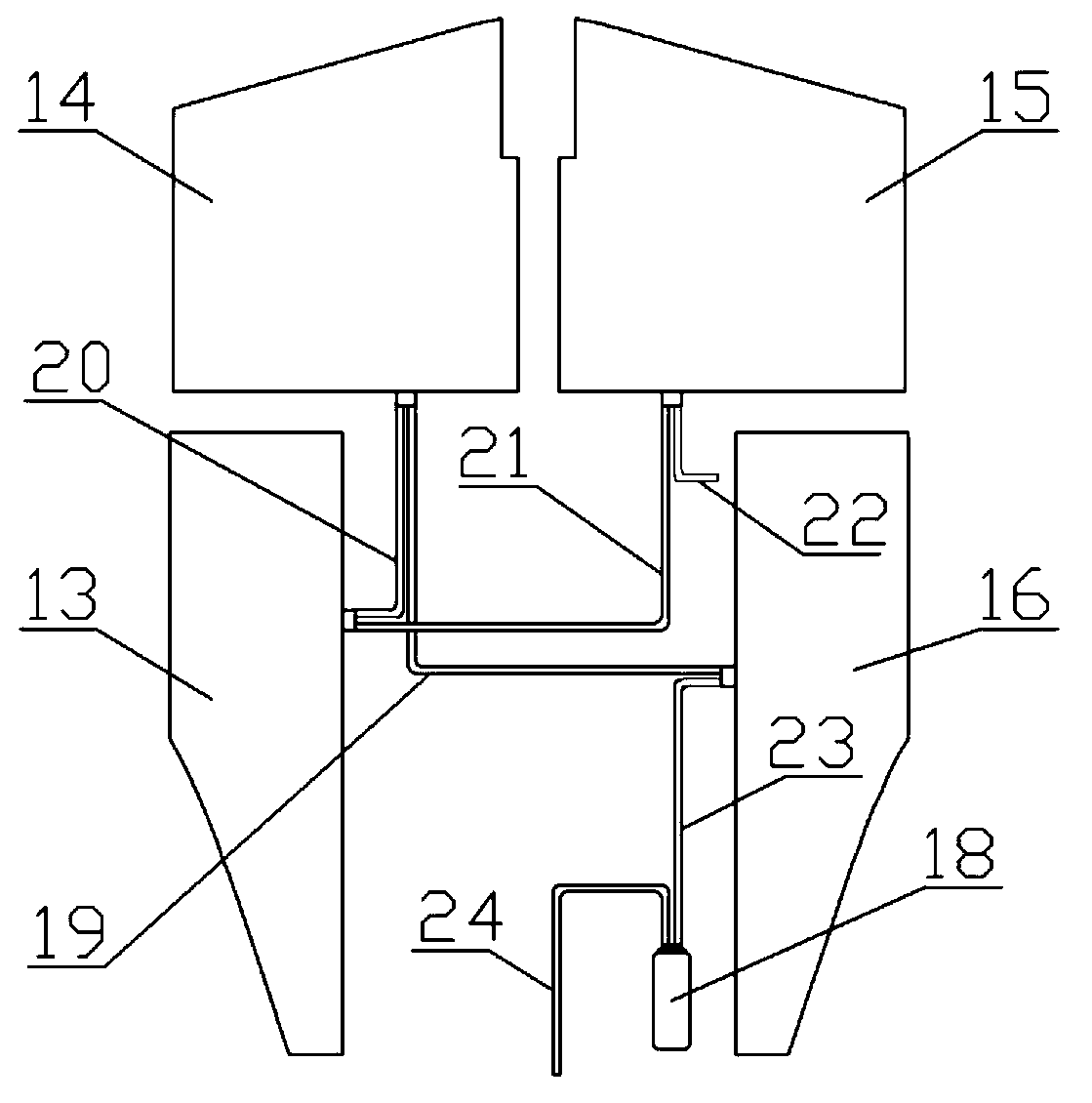

[0041] Example 1, long-endurance mission flight

[0042] The whole machine adopts wing-body fusion and "V"-shaped tail design and pull-in power plant, which has small resistance and high lift. Due to the installation of the embedded fuel tank that adopts the alternate fuel supply type, after the UAV takes off, the sequence of left rear fuel tank-right front fuel tank-right rear fuel tank-left front fuel tank is used to supply fuel to the engine in turn. During the process of fuel consumption, the whole machine The longitudinal change of the center of gravity is small, and due to the large volume of the fuel tank, a longer flight can be achieved.

example 2

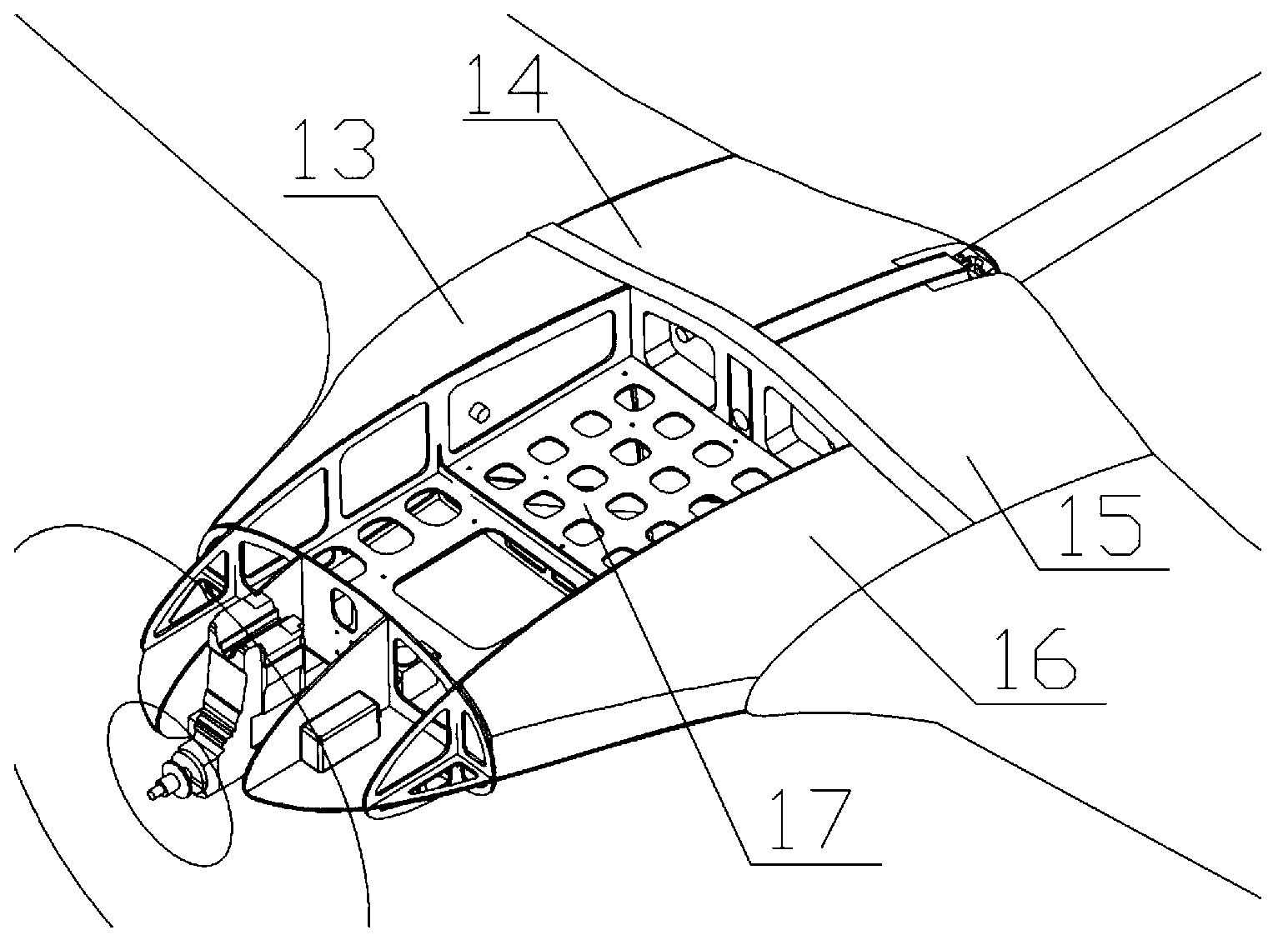

[0043] Example 2, rapid replacement of airborne equipment in routine tasks

[0044] Due to the low cost of the modular design of the airborne equipment base plate, multiple base plates can be manufactured, and various required airborne equipment can be installed on the base plate before the field test. During the field flight test, the bottom plate screws can be removed, and the “airborne equipment-bottom plate” module can be replaced to quickly change the configuration of the drone’s airborne equipment.

[0045] Beneficial effect

[0046] The advantages of the present invention are:

[0047]1) The small UAV adopts the layout type of wing-body fusion, single tail brace, V-shaped tail and pull-in power, which has excellent aerodynamic characteristics, especially the design of wing-body fusion increases the lift of the whole aircraft, Reduce wing-body interference resistance;

[0048] 2) Embedded fuel tank design is adopted to make full use of the internal space of the fusela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com