an aircraft

A technology for aircraft and fuselage, which is applied in the field of aircraft, can solve problems such as blade occupancy, fuselage strengthening strength, applicability, and reduced flexibility, and achieve the effects of reducing air resistance, strengthening stability, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

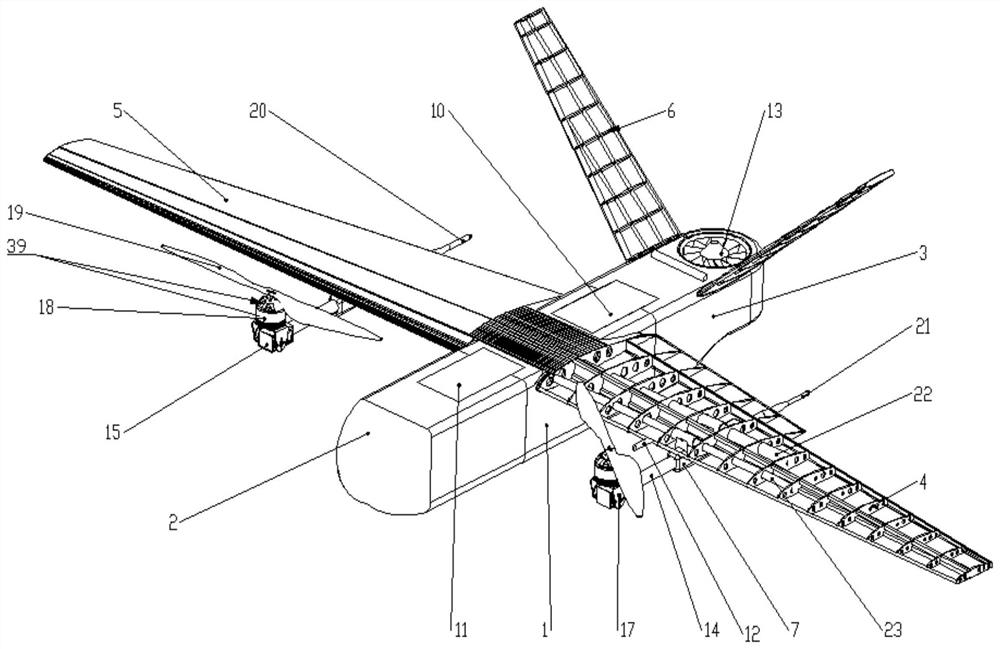

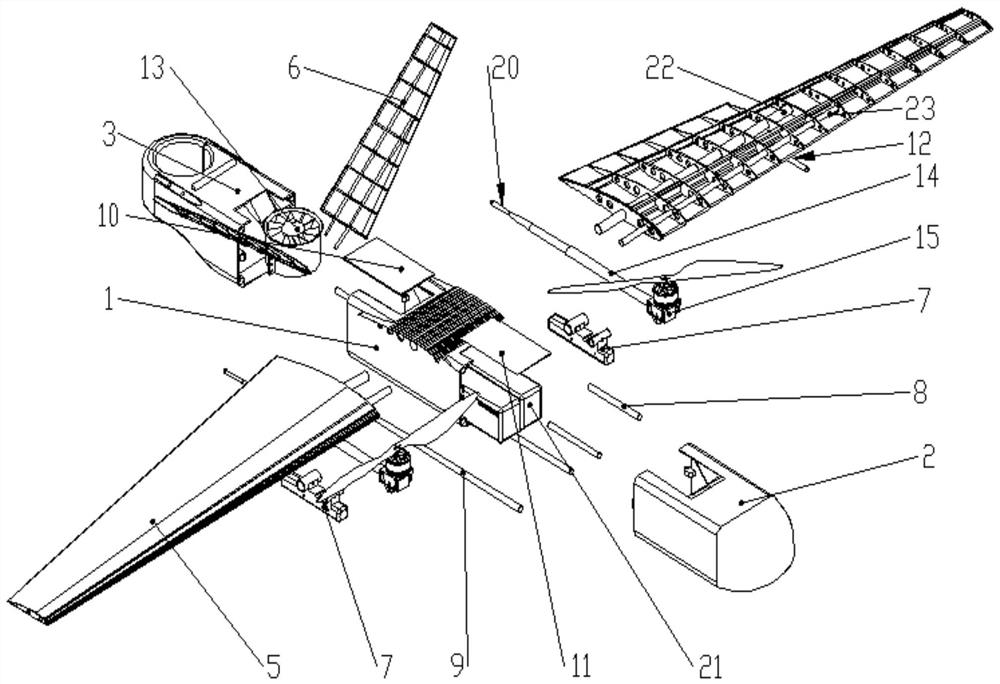

[0054] This embodiment provides an aircraft, comprising a fuselage, and wing assemblies arranged on both sides of the fuselage. The wing assembly includes the wing 5 and the tilting power assembly 39 arranged on the wing 5, and the wing assembly also includes a V-shaped empennage 6 arranged on the rear section 3 of the fuselage; the rear section 3 of the fuselage is set There is a detachable tail duct 13, which is provided with a tail duct motor inside the tail duct 13; this aircraft has a wingspan of 1740 (unit: millimeter mm, the same below), and a fuselage length of 834. A main wing with a length of 800 and a trapezoidal layout adopts the Clark-x airfoil inner and outer wing chord lengths of 250 and 150, and the wing angle of attack is 3°. The wing ribs are laminates with a thickness of 1mm. The 15 ribs are arranged equidistantly in sequence. Four 4*4 Paulownia wing beams are connected in groups of two to form the main and auxiliary beams of the wing. The main beam is locat...

Embodiment 2

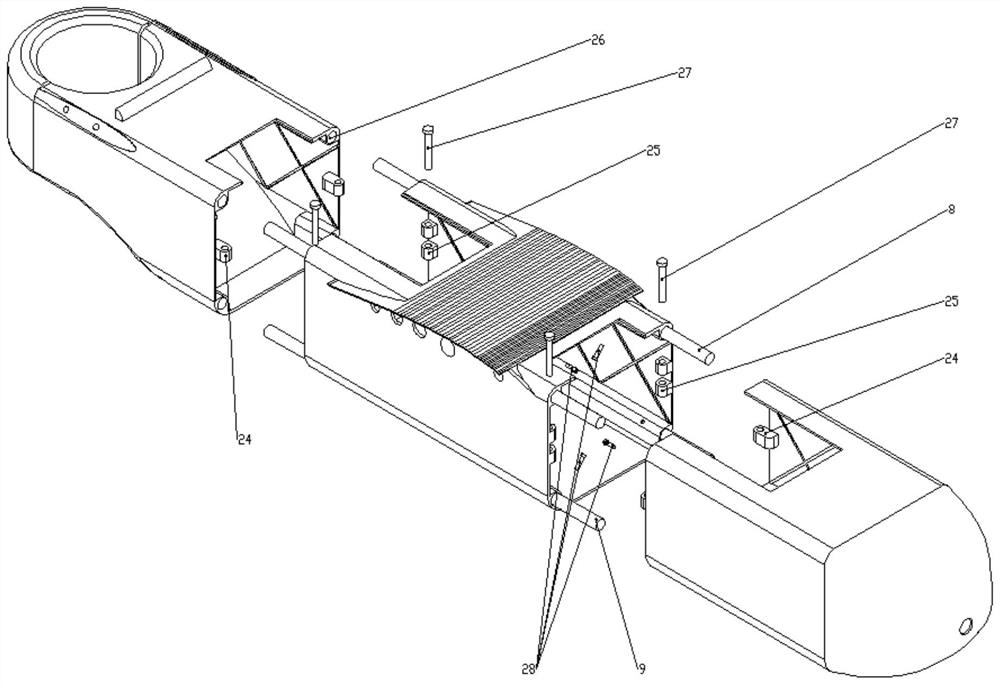

[0060] This embodiment is further optimized on the basis of Embodiment 1. Specifically, there is an R5 through hole that is consistent with the length of the middle section of the fuselage at the rounded corners on both sides of the bottom side of the middle section of the fuselage, and the R5mm hole that runs through the three sections of the fuselage. The carbon tubes form an interference fit. After the two carbon tubes at the bottom pass through the middle fuselage, there is an M5 screw hole passing through the center of the rounded corner at a distance of 20 from the front and back of the middle fuselage (the front refers to the direction of the machine head). One carbon tube There are two M5 screws at the front and back, and two carbon tubes on the bottom side of the middle fuselage, so there are four M3 screws in total to fix the carbon tube and the middle of the fuselage. There are R5 through holes with a length of 40 in the front and rear rounded corners of the middle s...

Embodiment 3

[0062]This embodiment is further optimized on the basis of embodiment 2. Specifically, there are R5 through holes of different lengths at the four rounded corners inside the front and rear sections of the fuselage, which form a clearance fit with the carbon tubes in the middle section of the fuselage. , and there is a protruding tenon in the middle of the opening of the front and rear sections of the fuselage. The front and rear sections of the fuselage can be slid in through the carbon tube. The three sections of the fuselage section are closed, and the bolts in the mortise and tenon structure enter the fuselage through the front and rear covers Internal and inserted in the mortise and tenon structure to form an interference fit in the section between the three sections of the fuselage. Thereby the three sections of the fuselage form a closed, firm and smooth integral fuselage. The mortise and tenon pin tube hole structure avoids the sliding of the front and rear sections of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com