High-temperature-resistant steel wire rope core lifting belt

A steel cord core and lifting belt technology, applied in the field of lifting belts, can solve the problems of poor heat resistance of high-temperature-resistant lifting belts, detachment of the rubber layer and the skeleton rope core, and easy aging cracks of the covering rubber, so as to achieve protection from aging and detachment, and improve Production efficiency, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

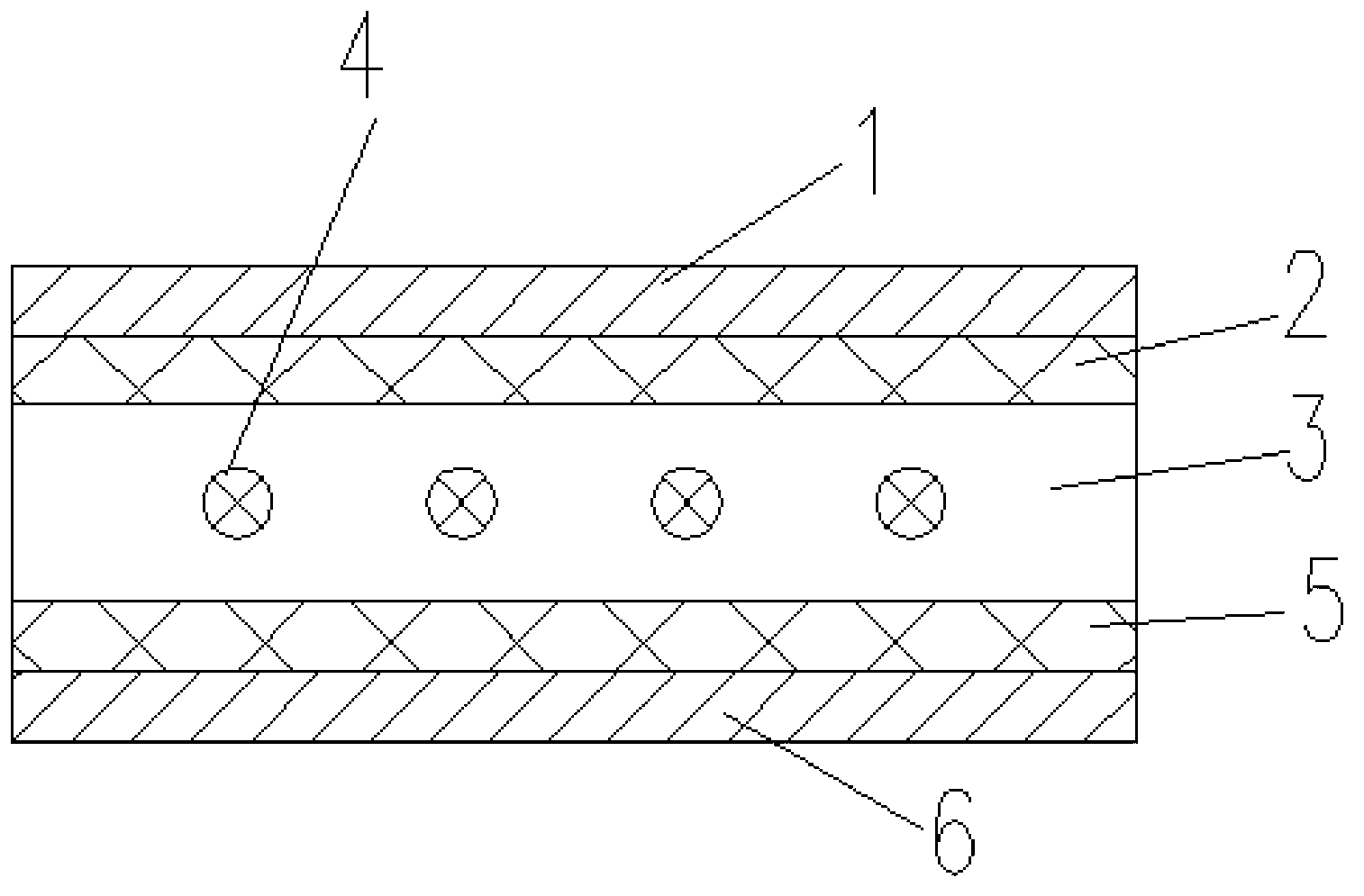

[0012] see figure 1 , which is a structural schematic diagram of a high-temperature-resistant steel cord hoisting belt provided by the present invention. Such as figure 1 As shown, a high temperature resistant steel cord core hoisting belt in the present invention comprises an upper anti-tear layer 2, a lower anti-tear layer 5, a core between the upper anti-tear layer 2 and the lower anti-tear layer 5 The rubber layer 3 and several evenly arranged longitudinal steel cord cores 4 wrapped in the core rubber layer 3 . Lay the upper insulation layer 1 with a thickness of 1-10mm above the upper anti-tear layer 2, and lay the lower insulation layer 6 with a thickness of 1-10mm below the lower anti-tear layer 5. Laying the upper heat insulation layer 1 and the lower heat insulation layer 6 above the top of the 2 and below the lower anti-tear layer 5 can effectively prevent the heat of the material from being transferred to the interior of the lifting belt. In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com