Biogas mixed gas and production process thereof

A technology for mixing fuel gas and production process, applied in gas fuel, fuel, petroleum industry and other directions, can solve the problem that natural gas cannot meet the market demand, and achieve the goal of being beneficial to rural energy conservation, emission reduction and ecological environmental protection, reducing the greenhouse effect and reducing damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

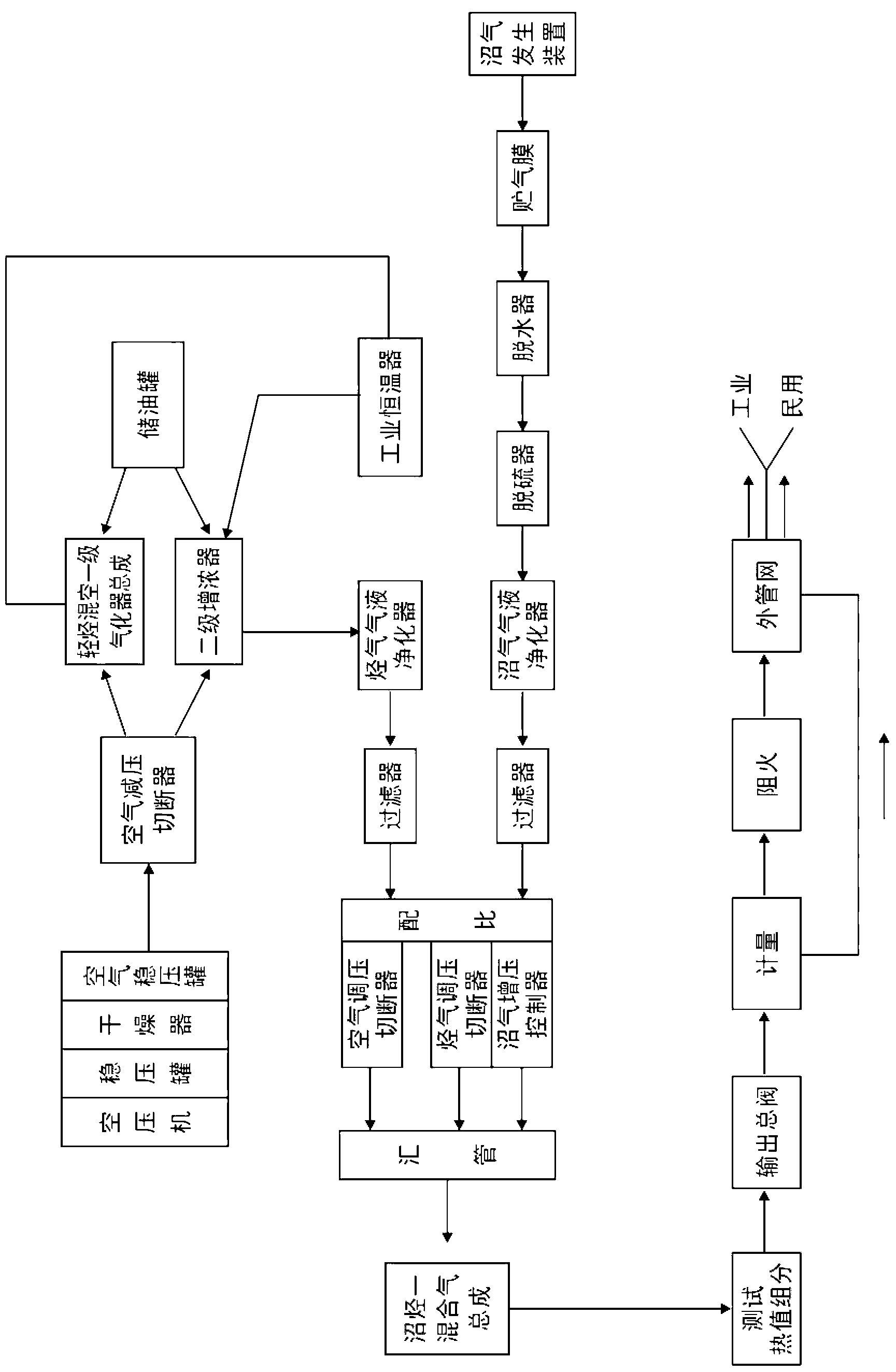

[0032] Embodiment 1 Preparation of mixed gas

[0033] The biogas produced during the fermentation of the biogas project meets the specified standards through desulfurization and purification, and then enters the gas-liquid separator for dehydration and filtration to obtain CH 4 Biogas with a content of 60% is used as the main gas source to be mixed. Liquid light hydrocarbons with a density of 0.63-0.68kg / L, 50% of the evaporation temperature not higher than 75°C, 90% of the evaporation temperature not higher than 135°C, and a total sulfur content of not more than 0.04% are produced by using vaporizer equipment. Under the conditions of rated liquid level, temperature, pressure, flow rate, etc., the air system automatically performs gas-liquid mass exchange with liquid light hydrocarbons in proportion, so that liquid light hydrocarbons are gasified, and the gasified light hydrocarbons mixed with air gas enter the gas-liquid separator. After separation, it is dehydrated and fil...

Embodiment 2

[0034] Embodiment 2 Preparation of mixed gas

[0035] The biogas produced by the biogas project, the desulfurization and dehydration treatment and the light hydrocarbon mixed gas gas production are the same as in Example 1 to obtain CH 4Biogas and civil light hydrocarbon mixed air gas with a content of 60% are measured by a flow meter, respectively enter the biogas and light hydrocarbon pressure regulating and proportioning devices, and then are sent to the biogas hydrocarbon mixer assembly for mixing according to the 6:4 pressure regulating and proportioning ratio. Mixed to obtain biogas mixed gas, the combustion calorific value is 23.46MJ / m 3 , the density of the mixed gas is 1.401kg / m 3 , the relative density is 1.08, the Huabai number W=22.58MJ / m 3 . Composition test value of mixed gas (component content CV value): CH 4 is 36%, CO 2 24%, air 32.8%, iso-light hydrocarbons 7.2%. The explosion limit of mixed gas: the upper limit is 19.16%, the lower limit is 5.639%, a...

Embodiment 3

[0036] Embodiment 3 Preparation of mixed gas

[0037] The biogas produced by the biogas project, desulfurization and dehydration treatment and light hydrocarbon mixed air gas gas production are the same as in Example 1, and CH is obtained 4 Biogas and civil light hydrocarbon mixed air gas with a content of 60% are measured by a flow meter, respectively enter the biogas and light hydrocarbon pressure regulating and proportioning devices, and then are sent to the biogas hydrocarbon mixer assembly for blending according to the 2:8 pressure regulating and proportioning ratio. Mixed to obtain biogas mixed gas, the combustion calorific value is 25.40MJ / m 3 , the mixed gas density is 1.588kg / m 3 , the relative density is 1.23, the Huabai number W=22.90MJ / m 3 . Composition test value of mixed gas (component content CV value): CH 4 is 12%, CO 2 8%, air 65.6%, light hydrocarbons 14.4%. The explosion limit of mixed gas: the upper limit is 13.16%, the lower limit is 3.00%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com