A Reinforcement Method for Cracking of Prestressed Continuous Beam Bottom Plate

A prestressing and bottom plate technology, which is applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of prestressed continuous beam bottom plate cracking and negative effects, and achieve the effect of reducing the difficulty of reinforcement construction, ingenious conception, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

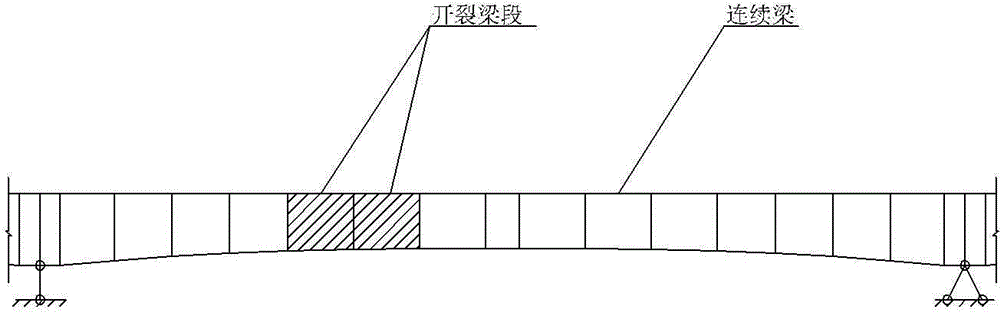

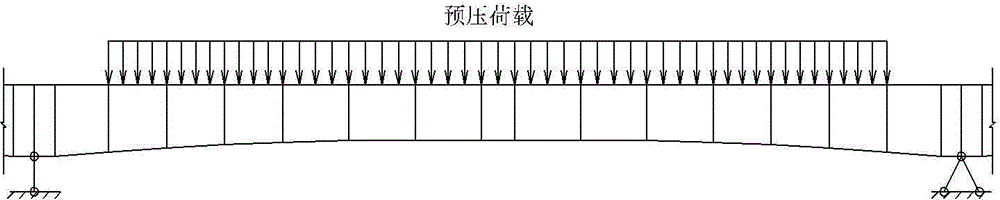

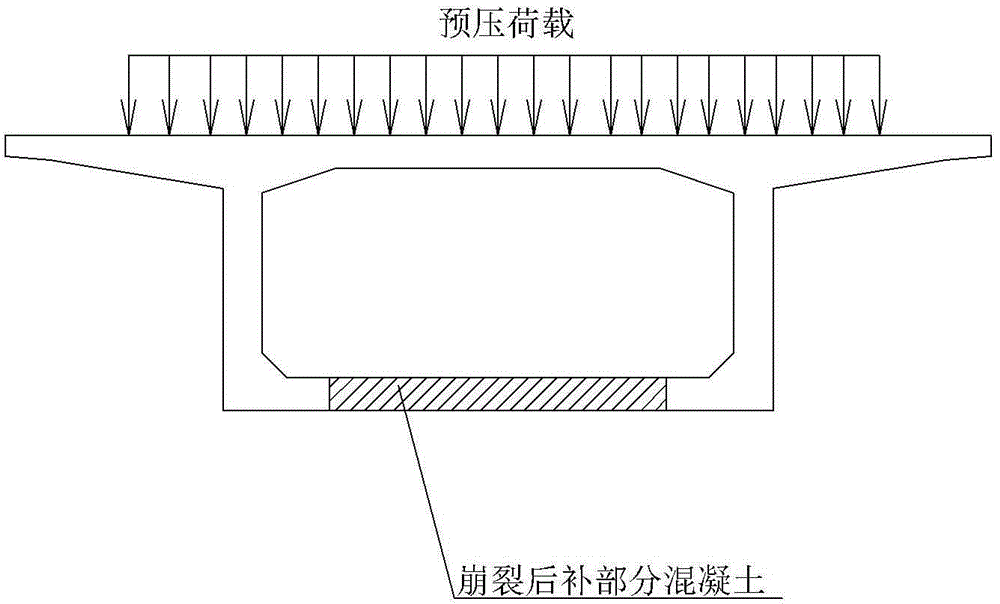

[0025] After the prestressed concrete continuous beam of a passenger dedicated line was prestressed and grouted, a large area of cracking occurred at the bottom of the middle hole beam. The bridge hole span layout adopts (30.15+48+56+48+30.15)m continuous box girder, the top width of the box girder is 12.0m, and the bottom width is 6.7m. The bottom plate is cracked, falling off, and there are many cracks, the width of the crack is 1mm~2mm, and the width of the crack is about 50mm at the place where the concrete falls off; the bottom plate is cracked and delaminated, and the steel mesh of the bottom plate sinks up to about 14.7cm; there are many voids under the protective layer on the top surface of the bottom plate , the steel mesh sinks, and when viewed from the inside of the box, the bottom plate cracks and delaminates from the longitudinal prestressed bellows.

[0026] After a comprehensive analysis of the reasons for the cracking, after analyzing and comparing the advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com