Method for extracting natural gas hydrate through CO2/N2 underground replacement

A technology for hydrate and natural gas, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., and can solve problems such as low permeability and low heat and mass transfer in hydrate layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

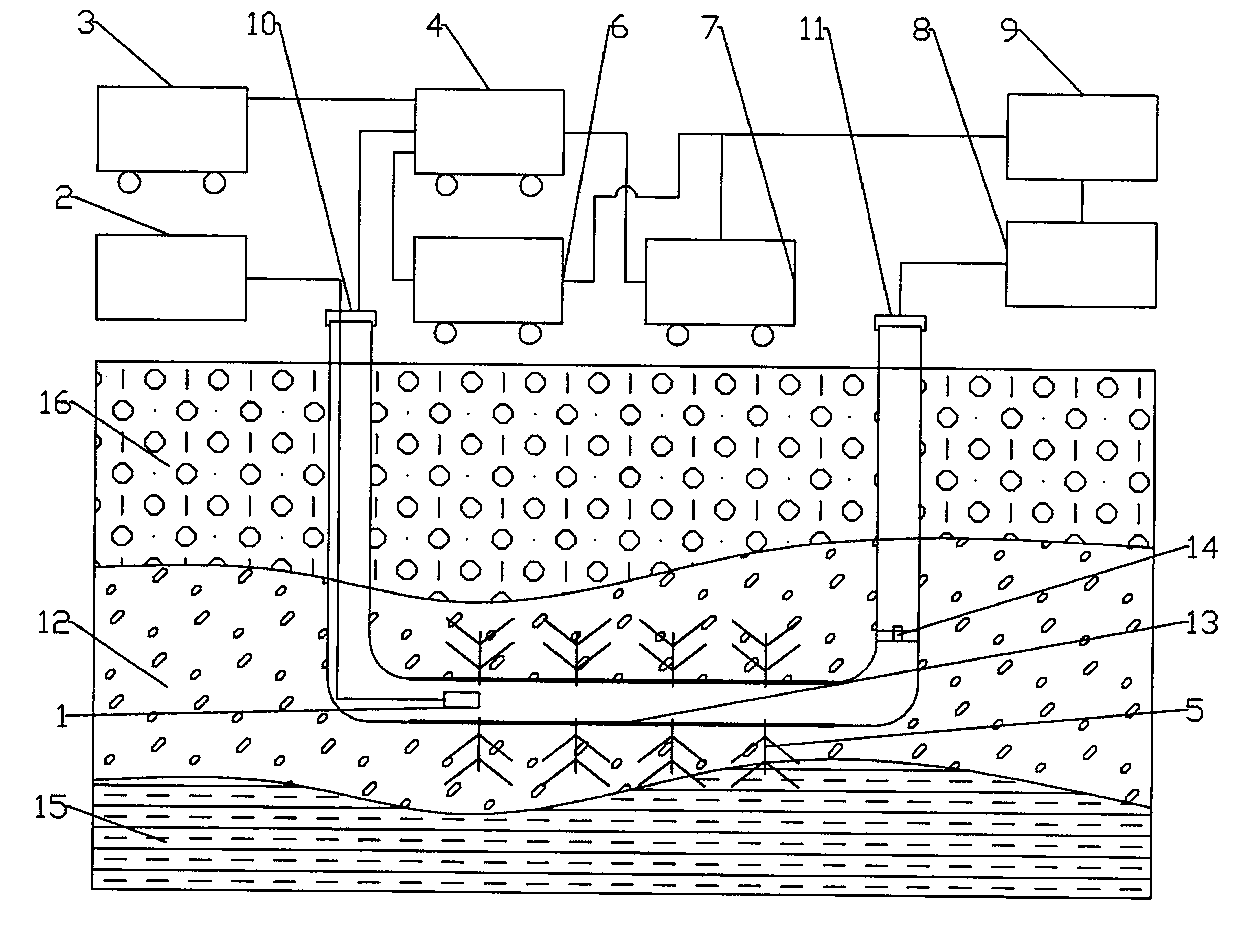

[0022] Example 1: Reduced pressure mining combined with CO 2 / N 2 Displacement mining, see figure 1 Shown:

[0023] Step 1: Implement two vertical wells—injection well 10 and production well 11. The two vertical wells pass through the hydrate overlying formation 16 to the hydrate layer 12. The horizontal well 13 is set in the hydrate layer 12. The horizontal well 13 The length and number of layers are determined according to the scope and thickness of hydrate reservoirs; after the drilling is completed, cementing and completion are carried out, and some monitoring instruments such as temperature sensors, pressure sensors and flow meters are installed to monitor the downhole temperature, pressure and flow rate. and other parameters are monitored, and the monitoring instrument 1 is connected to the surface data acquisition and processing system 2 to collect and process the data for analysis of the mining process and next-step work guidance. A hydrate layer 12 is located on an...

Embodiment 2

[0028] Example 2: Liquid CO 2 Displacement bound CO 2 / N 2 Displacement mining, see figure 1 Shown:

[0029] Step 1: Same as Step 1 in Example 1.

[0030] Step 2: The process is roughly the same as Step 2 in Example 1, except that liquid CO is used 2 As a fracturing fluid, CO 2 Preparation of CO in cart 6 2 Carry out liquefaction, pump into the closed mud sand device vehicle 3, and then pump into the well through the fracturing pump vehicle 4 to implement the fracturing process.

[0031] Step 3: After the fracturing is completed, adjust the pressure to the pressure range of the replacement reaction, and carry out CO2 replacement production; after a period of replacement, control the gas production pressure through the pressure controller on the plug 14, and the gas collected from the production well 11 passes through the gas The liquid separation device 8 performs gas-water separation, and then performs gas separation through the gas separation device 9 to store natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com