Air-cooling condenser structure containing horizontal shaft axial flow fan group

A technology for air-cooled condensers and axial flow fans, which is applied to steam/steam condensers, lighting and heating equipment, etc., and can solve the problem of limited flow at the inlet of axial flow fans, distortion of flow at the inlet of axial flow fans, and difficult driving of fans Cooling air flow and other issues, to avoid serious distortion of fan inlet flow, reduce pipeline consumption and project cost, and improve aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

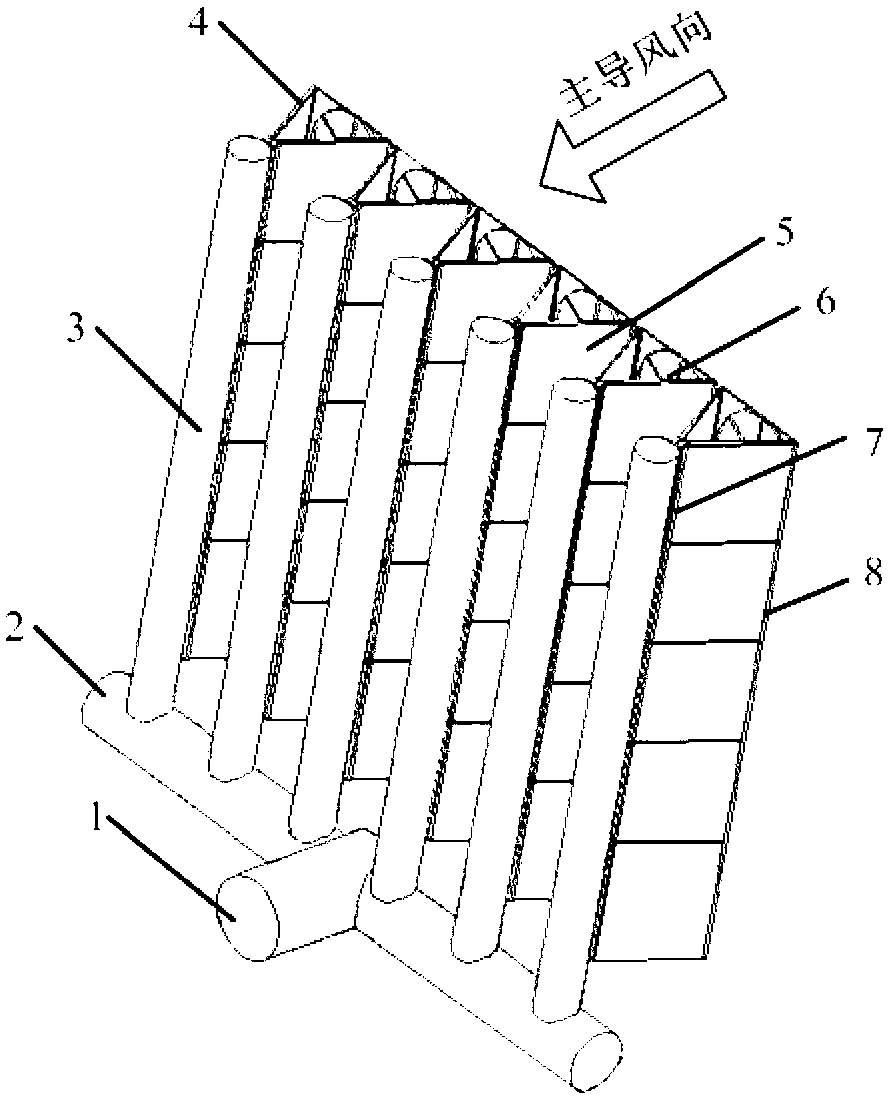

[0010] The present invention proposes a novel structure of an air-cooled condenser including a group of horizontal-axis and axial-flow fans. The present invention will be described below in conjunction with the accompanying drawings.

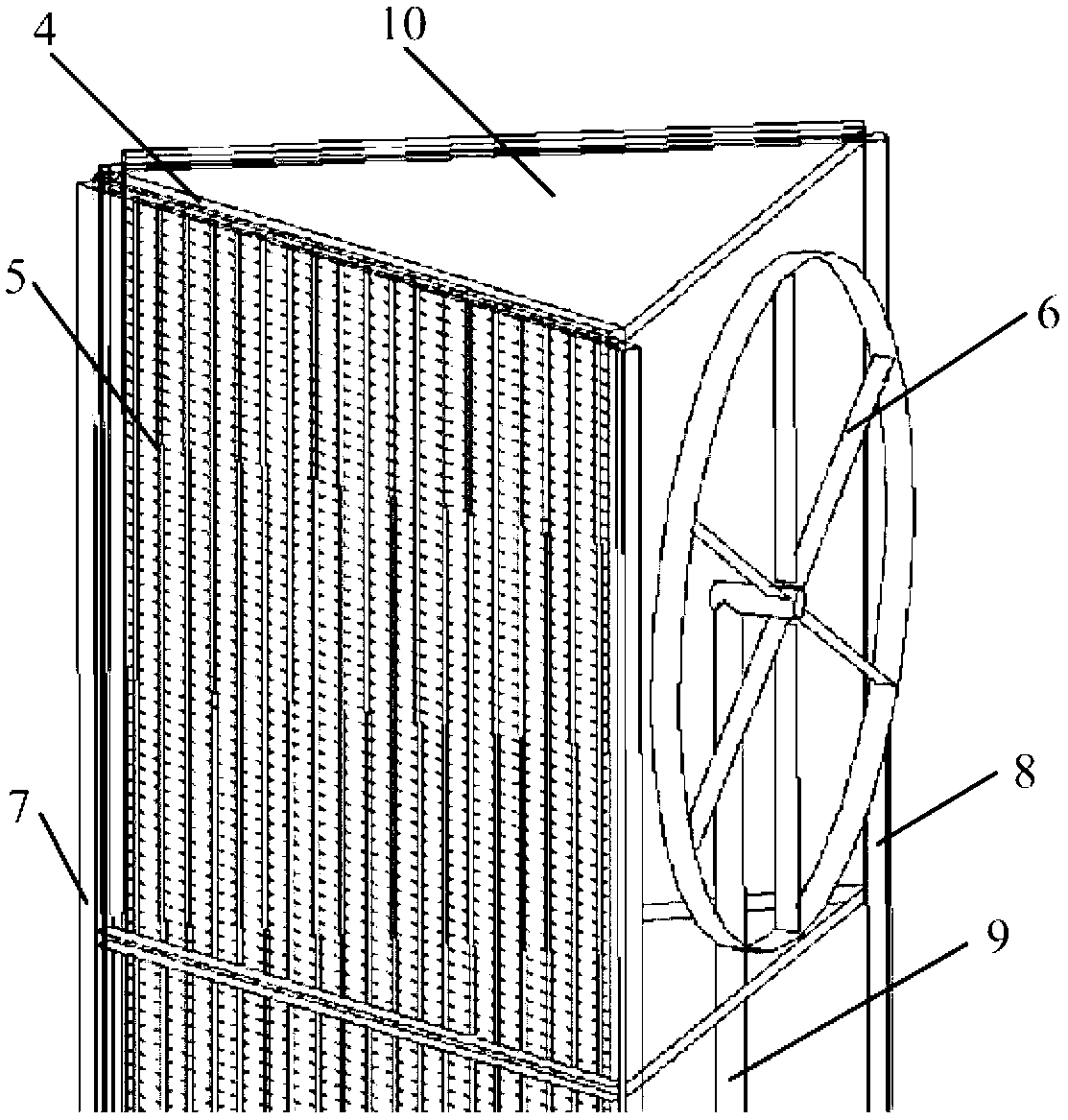

[0011] exist figure 1 In the schematic diagram of the structure of the air-cooled condenser including the horizontal axial flow fan group, the main steam pipe 1 and the horizontal steam branch pipe 2 are welded in a cross, and each row of vertical steam distribution pipes 3 is welded vertically on the horizontal steam branch pipe 2 at equal distances. , along the axial direction of the steam distribution pipe 3, the fixed support column 7 and the triangular bottom column 8 form a triangular frame structure with the upper and lower surfaces 10 of the welded tube bundle parallel to the axial direction of the steam distribution pipe. The finned tube bundles 5 are arranged vertically (such as figure 2 shown) and connected to the steam distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com