Treatment methods of landfill leachate and treatment systems thereof

A technology of landfill leachate and treatment method, which is applied in the field of waste water multi-stage treatment method and its treatment system, which can solve the problems of high cost, difficult to solve landfill leachate, poor effect, etc., achieve short construction period, easy automatic control and operation , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

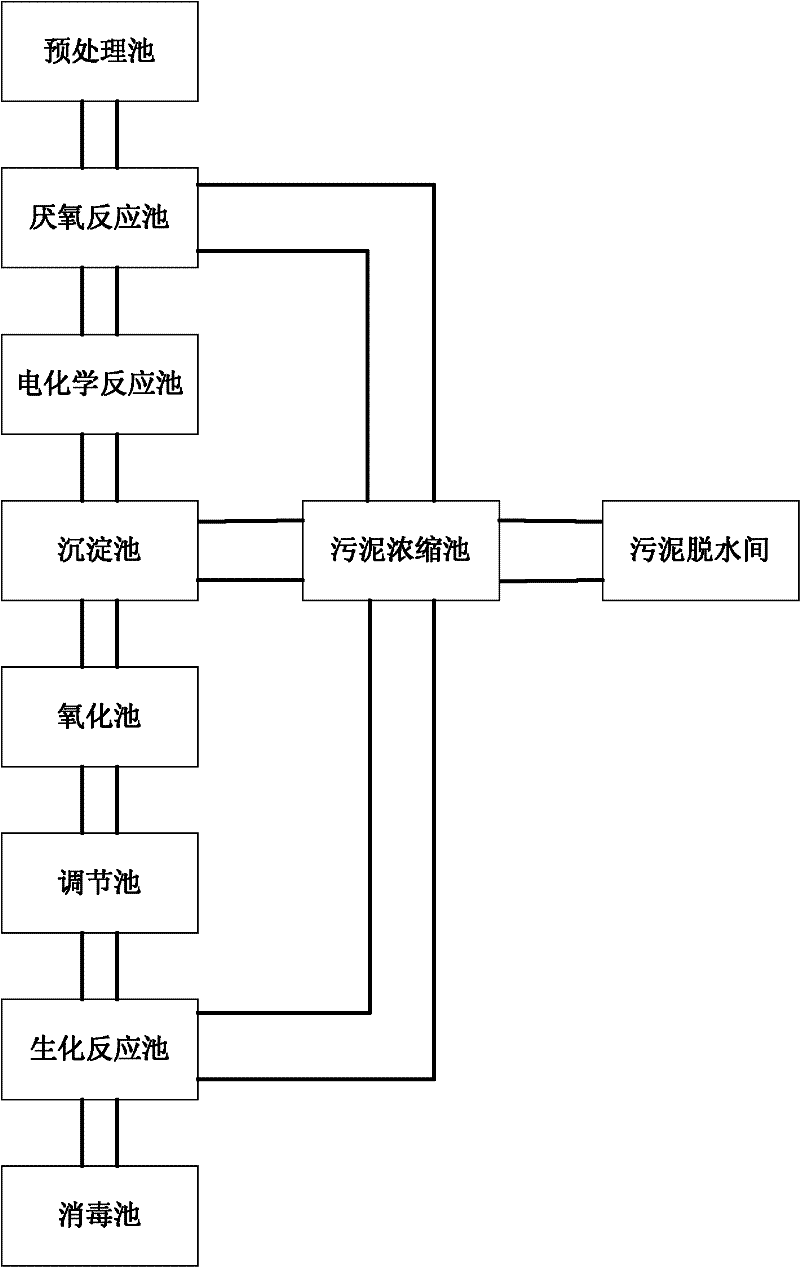

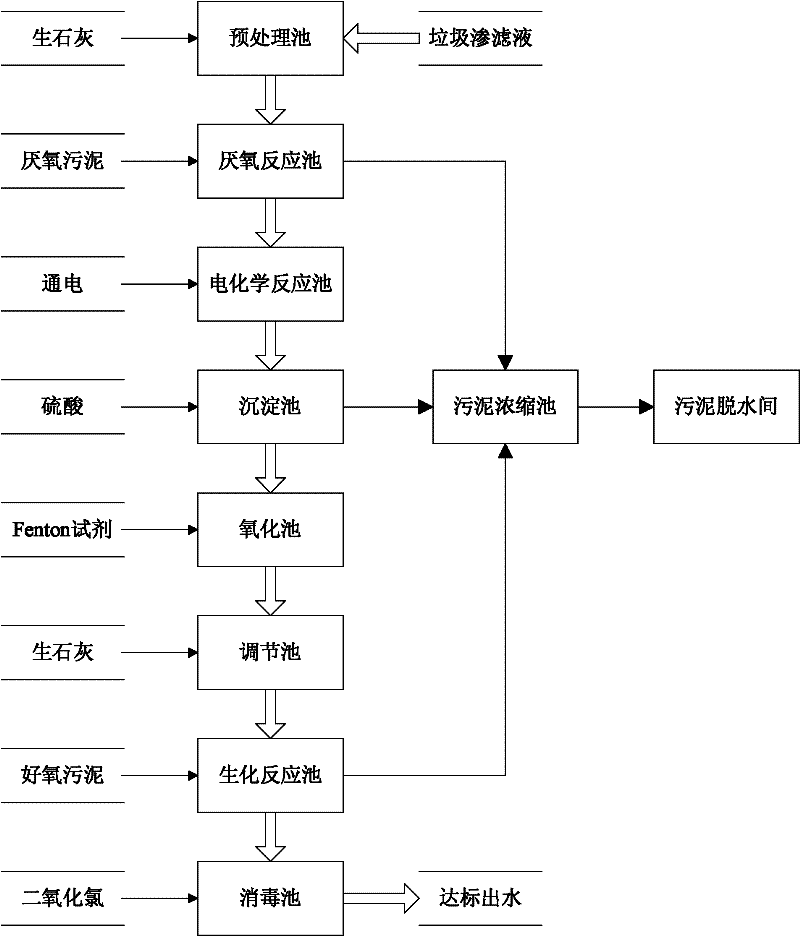

[0047] a kind of like figure 1 The shown landfill leachate treatment system applied in the treatment method of the present invention includes a sequentially connected pretreatment tank, anaerobic reaction tank, electrochemical reaction tank, sedimentation tank, oxidation tank, regulation tank and biochemical reaction tank , each treatment tank is equipped with a liquid inlet and a liquid outlet, and each treatment tank is connected in turn through pipes (or ditches); anaerobic sludge is filled in the anaerobic reaction tank, and anaerobic sludge is filled in the electrochemical reaction tank Two electrochemical reactors are installed, each electrochemical reactor is equipped with a stirring device, Fenton reagent is added in the oxidation tank, and aerobic sludge is filled in the biochemical reaction tank; among them, the anaerobic reaction tank In addition to the aforementioned liquid inlet and outlet, the sedimentation tank and the biochemical reaction tank are each equipped...

Embodiment 2

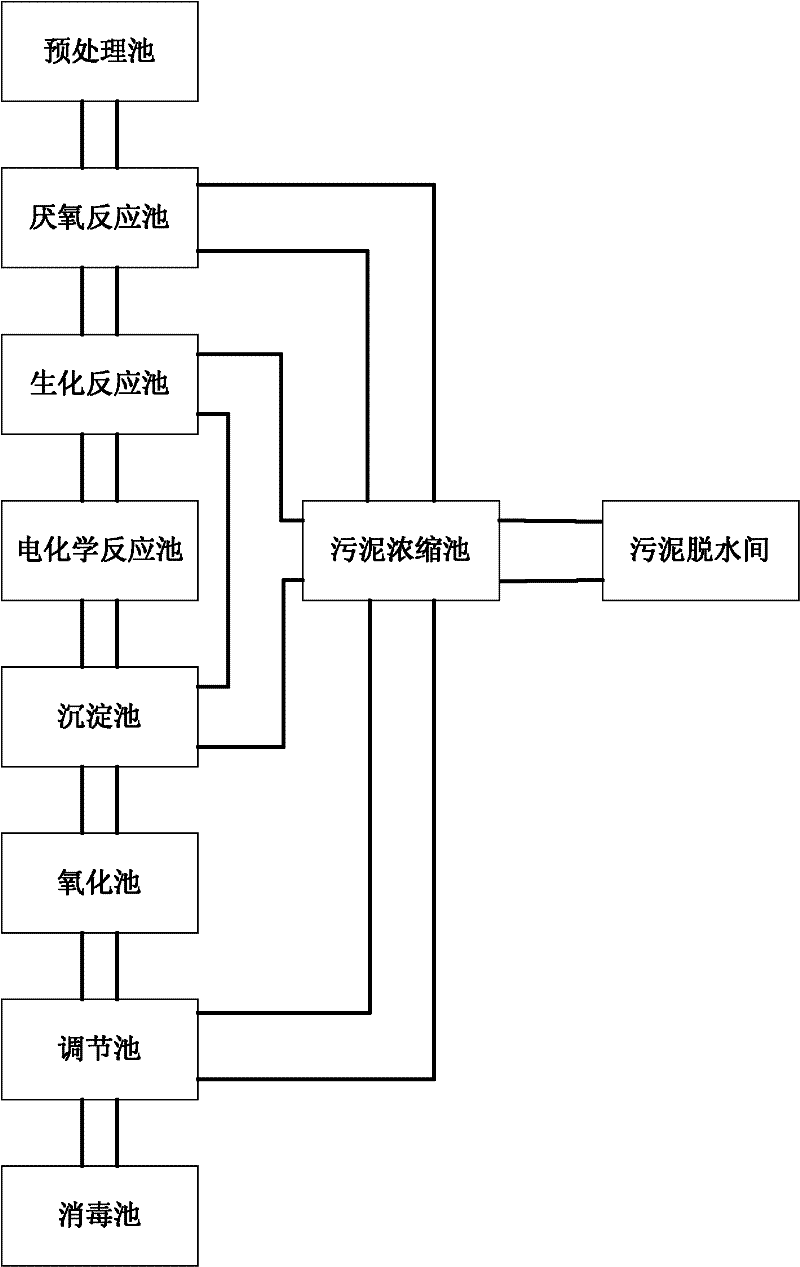

[0059] a kind of like image 3 The shown landfill leachate treatment system applied in the treatment method of the present invention includes sequentially connected pretreatment tanks, anaerobic reaction tanks, biochemical reaction tanks, electrochemical reaction tanks, sedimentation tanks, oxidation tanks and adjustment tanks , each treatment tank is equipped with a liquid inlet and a liquid outlet, and each treatment tank is connected in turn through pipes (or ditches); anaerobic sludge is filled in the anaerobic reaction tank, and anaerobic sludge is filled in the biochemical reaction tank. Aerobic sludge is placed, two electrochemical reactors are installed in the electrochemical reaction pool, each electrochemical reactor is equipped with a stirring device, and Fenton reagent is added in the oxidation pool; among them, the anaerobic reaction pool , biochemical reaction tank, sedimentation tank and regulating tank are provided with the aforementioned liquid inlet and outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com