Automatic paper scrap-pressing device for combined fireworks

A combination of fireworks and paper pressing technology, which is applied in the direction of offensive equipment, fireworks, weapon types, etc., can solve the problems of unguaranteed quality of fireworks, influence on the progress of fireworks production, and uneven product quality, so as to improve the quality of products , Improve product quality and output, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

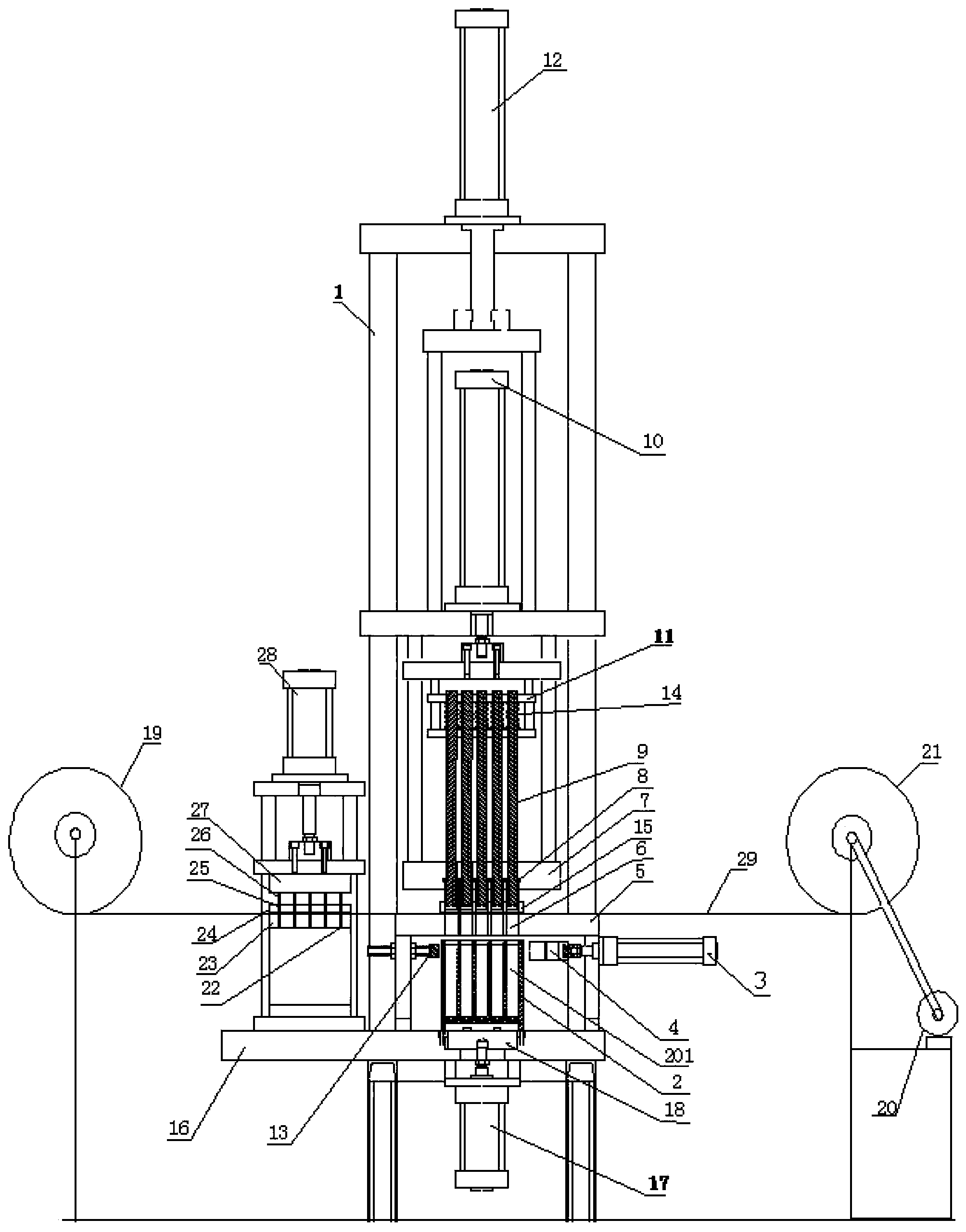

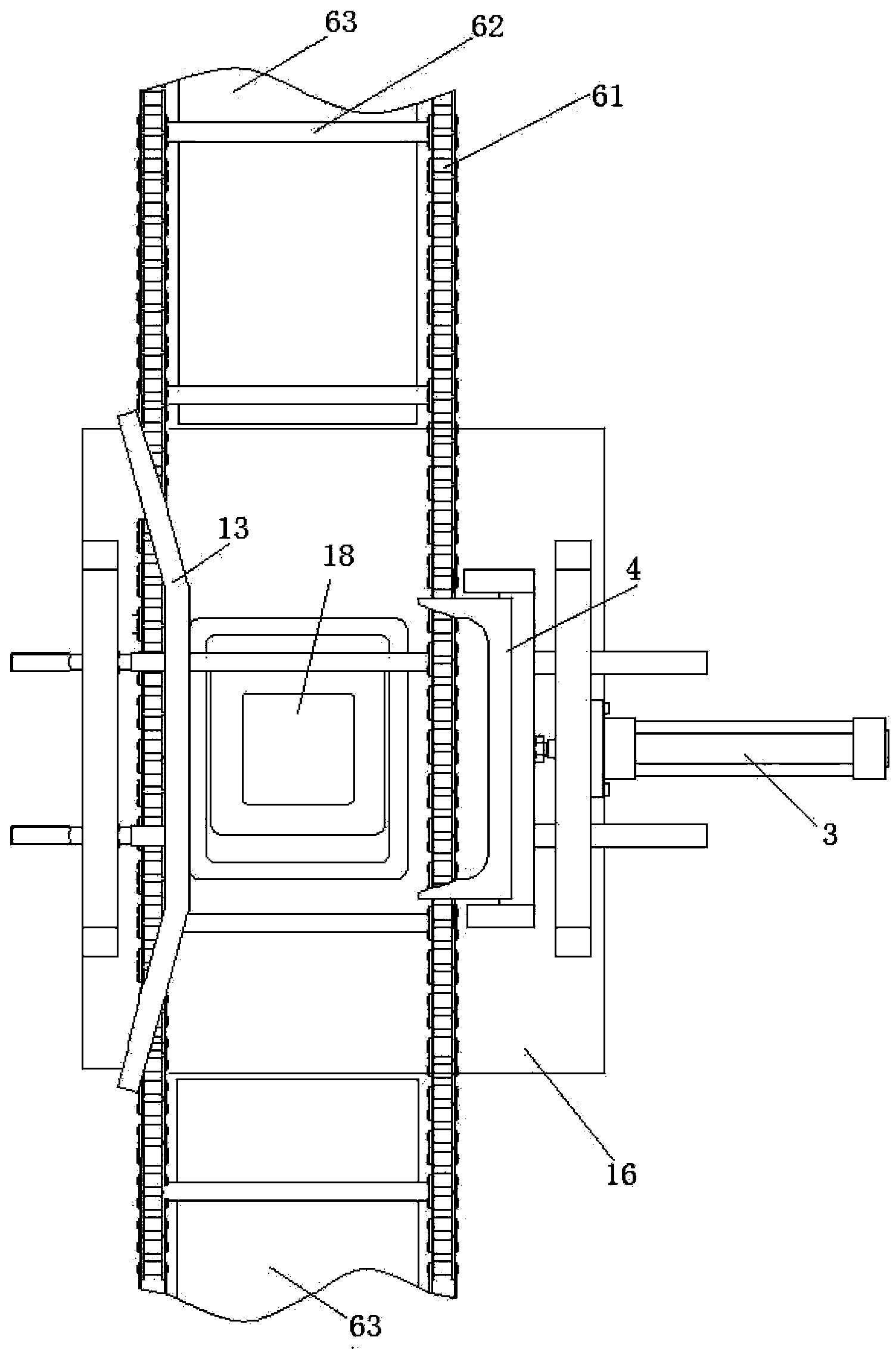

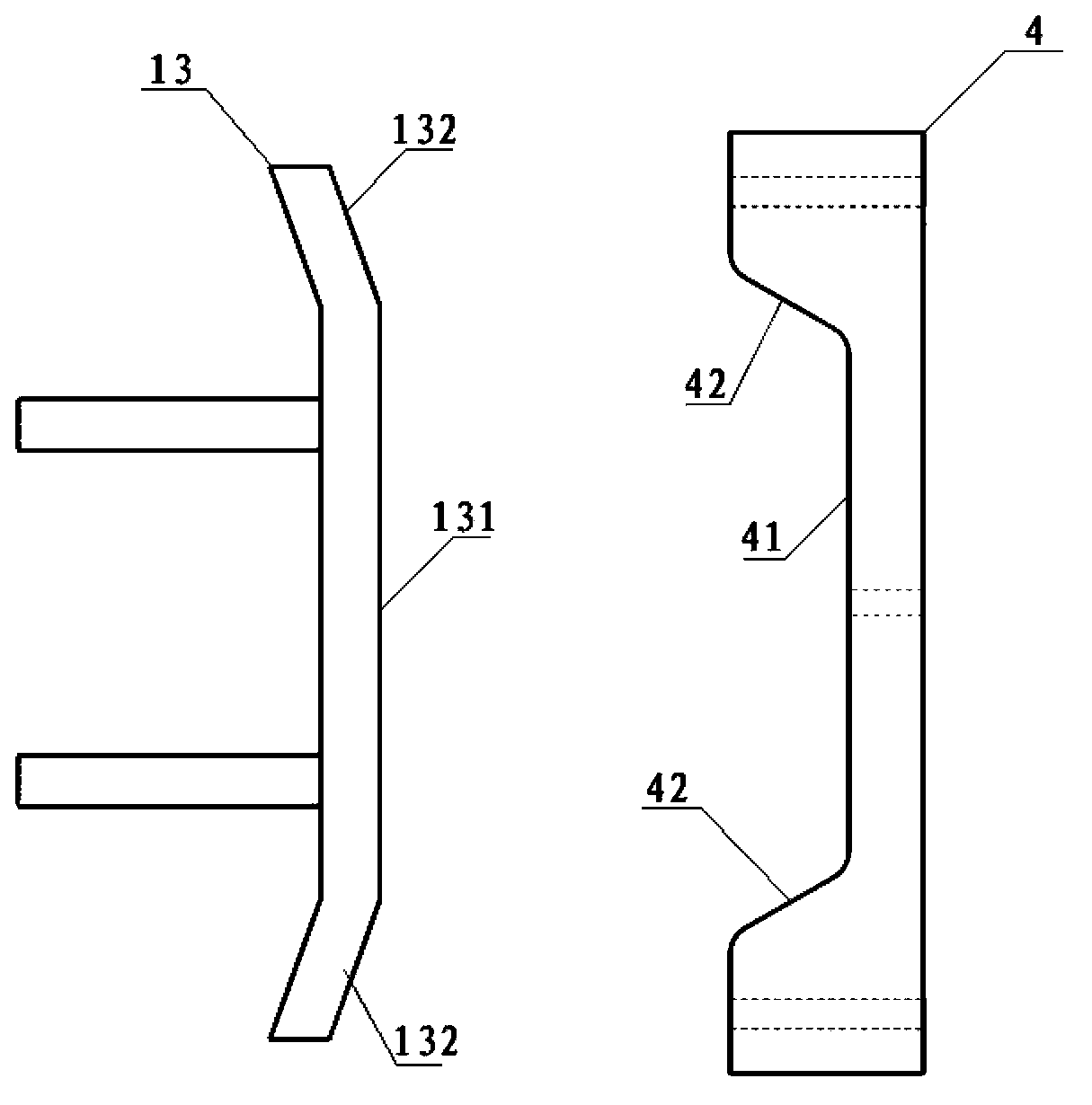

[0024] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the combined firework automatic sheet pressing equipment includes a fireworks outer cylinder positioning mechanism and a circular paper sheet production and pressing mechanism installed on the frame 1: the fireworks outer cylinder positioning The mechanism includes a positioning assembly, the first positioning element 4 and the second positioning element 13 of the positioning assembly are respectively located at the corresponding positions on the two opposite sides of the fireworks outer tube 2, the first driving mechanism adopts the cylinder 3, and can also use a motor or hydraulic mechanism. The cylinder 3 is connected and fixed to the first positioning element 4 through bolts and cylinder joints, and the second positioning element 13 is corresponding to it. When the fireworks outer cylinder 2 is placed at the corresponding position of the processing station and is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com