Ultrasonic vibration three-point bending test device suitable for observing crisp and hard material on line

A technology of ultrasonic vibration and three-point bending, which is applied in the direction of testing the strength of materials by applying stable bending force and testing the strength of materials by applying repetitive force/pulsating force, and can solve the problem of not exploring the influence of ultrasonic vibration on the intrinsic properties of materials, Not suitable for online observation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

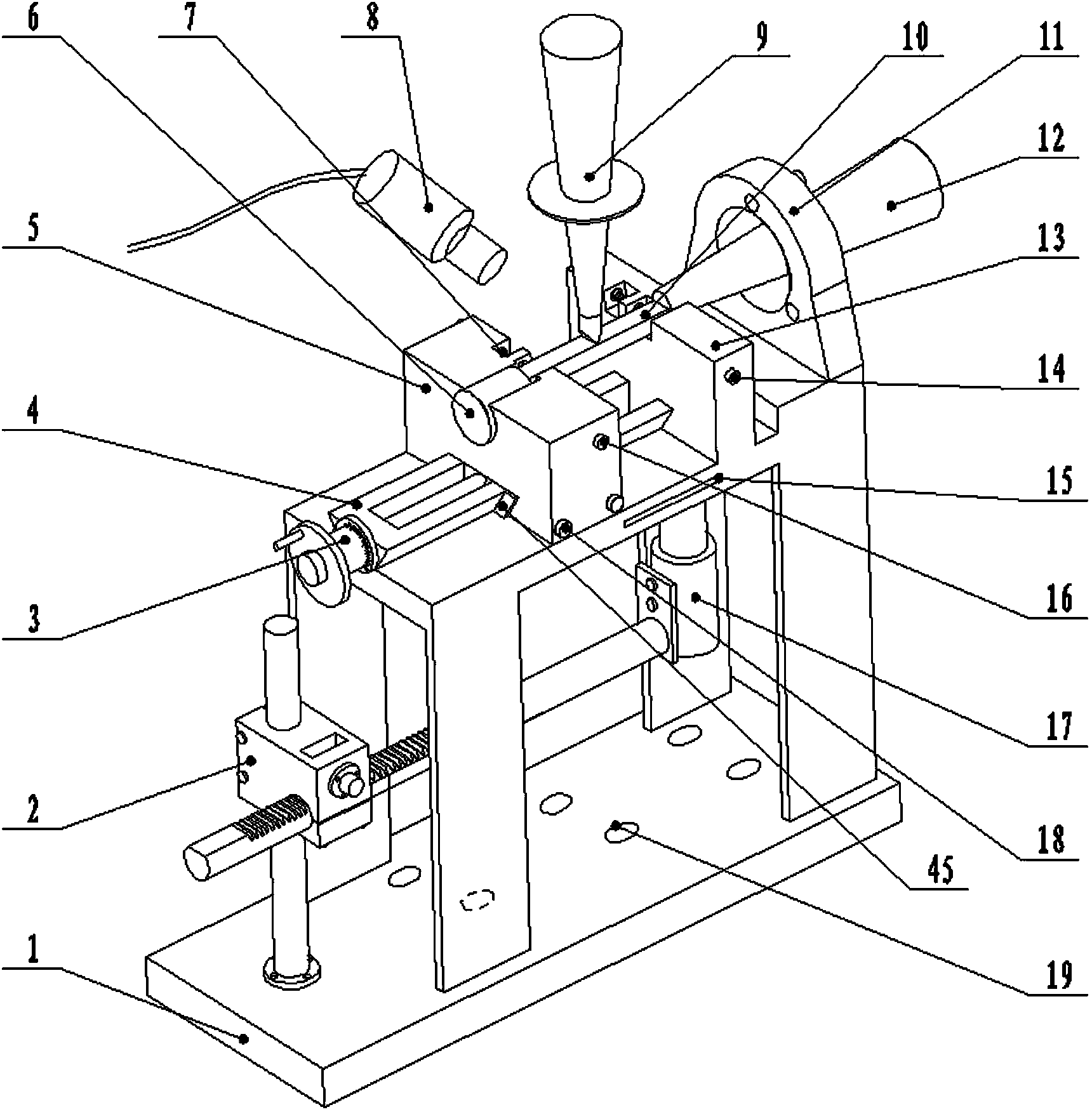

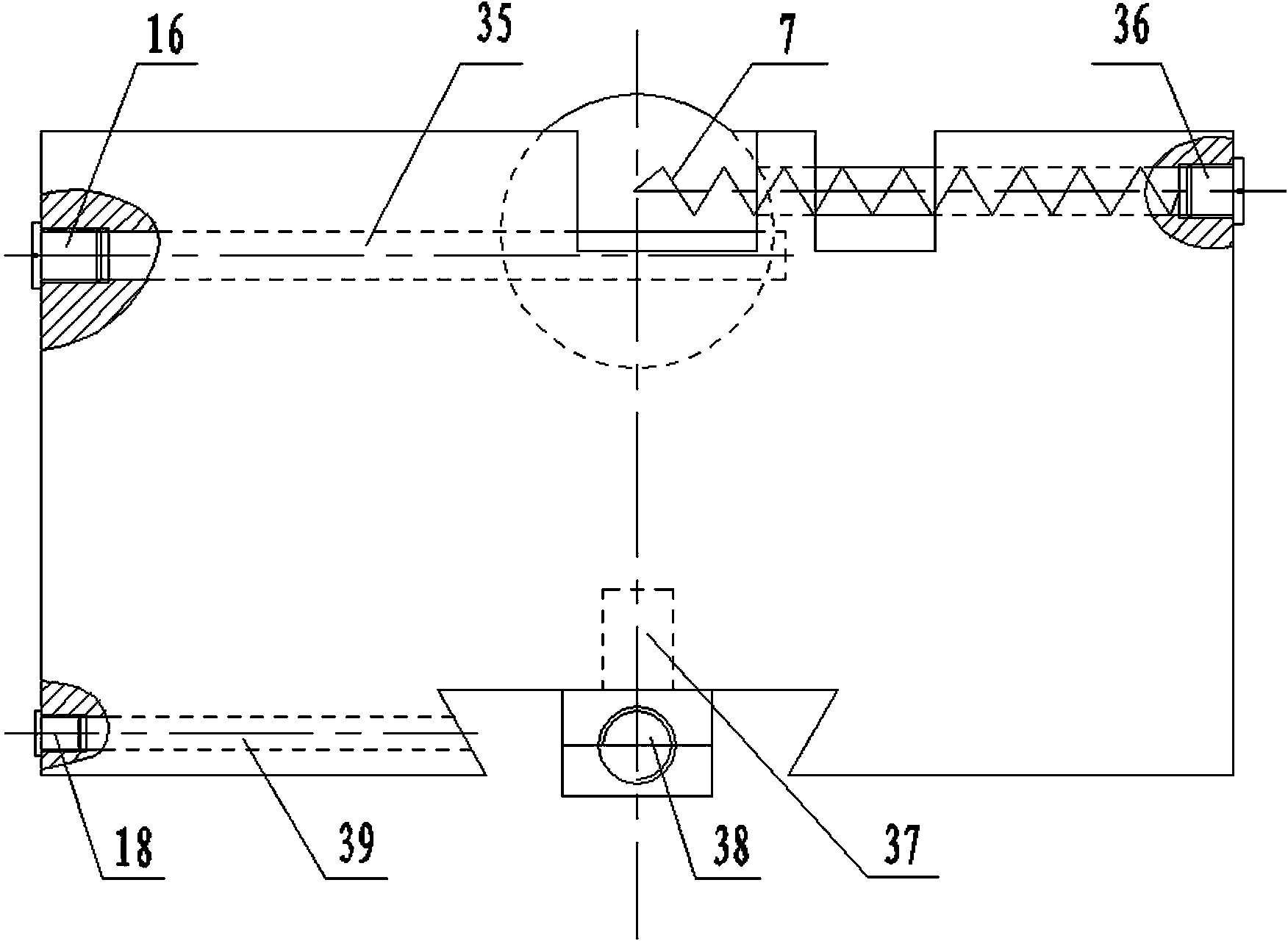

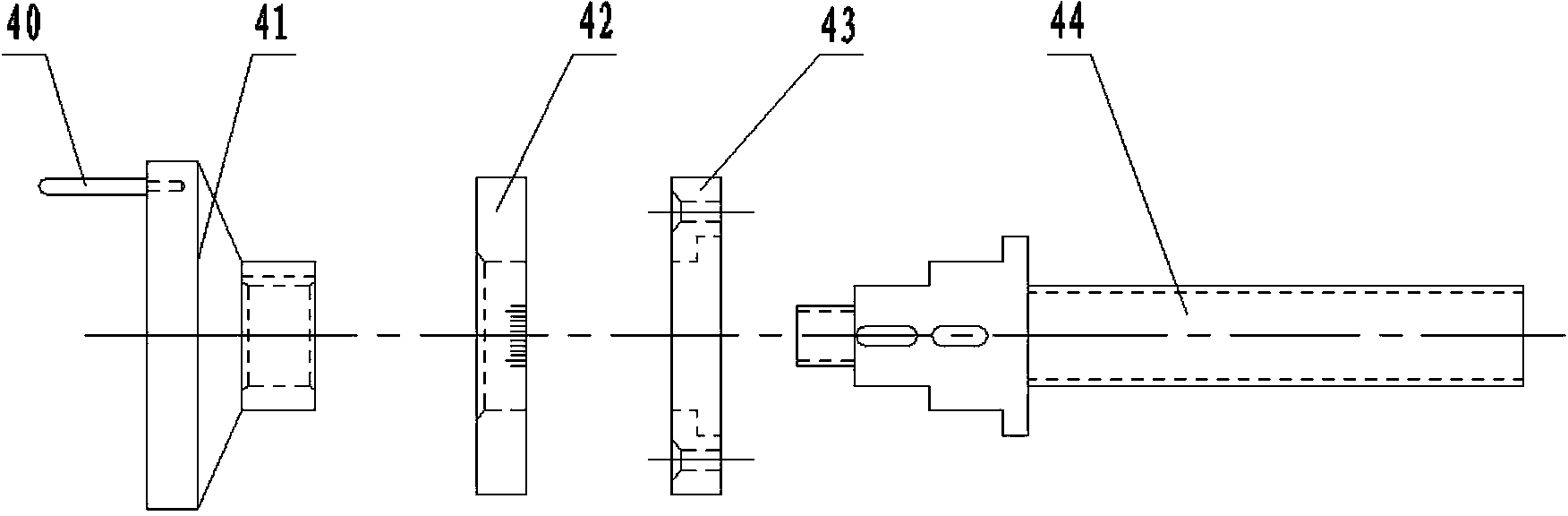

[0026] Example: such as Figure 1-6 As shown, an ultrasonic vibration three-point bending test device suitable for on-line observation of hard and brittle materials includes a cube-shaped support 1, the bottom plate of the support 1 and the upper plate are integrated, and the three-point bending device is fixed on the ultra-precision measuring device through bolt holes 19. On the force gauge, the force gauge is placed on the hydraulic testing machine to measure the pressure when the ceramic specimen breaks. The bracket 1 is in the shape of a cube with a large space, and can realize online observation of the fracture process of the ceramic sample from multiple angles.

[0027] There is a window slot 15 on the front side of the flat plate on the bracket 1, the window slot 15 is rectangular, and the quartz glass is installed in the window slot 15 to facilitate the high-speed photographic lens 1 to photograph the dynamic process of the ceramic fracture and prevent the ceramic frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com