Extruding and drawing device for in-situ structure detection in combination with scattering of X rays and experimental method thereof

A technique for tensile devices, structural inspection, applied in measurement devices, material analysis using radiation diffraction, material analysis using wave/particle radiation, etc., can solve problems such as disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Below in conjunction with accompanying drawing and embodiment further illustrate the present invention.

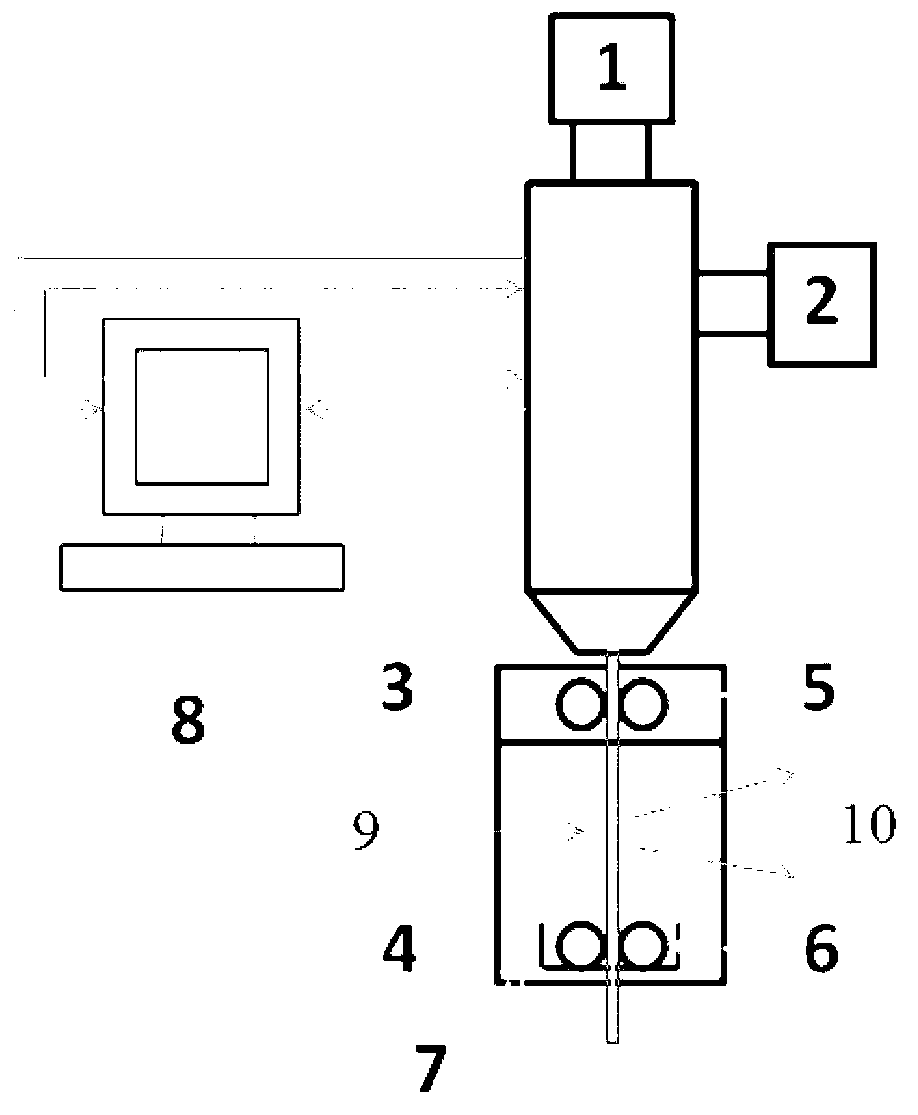

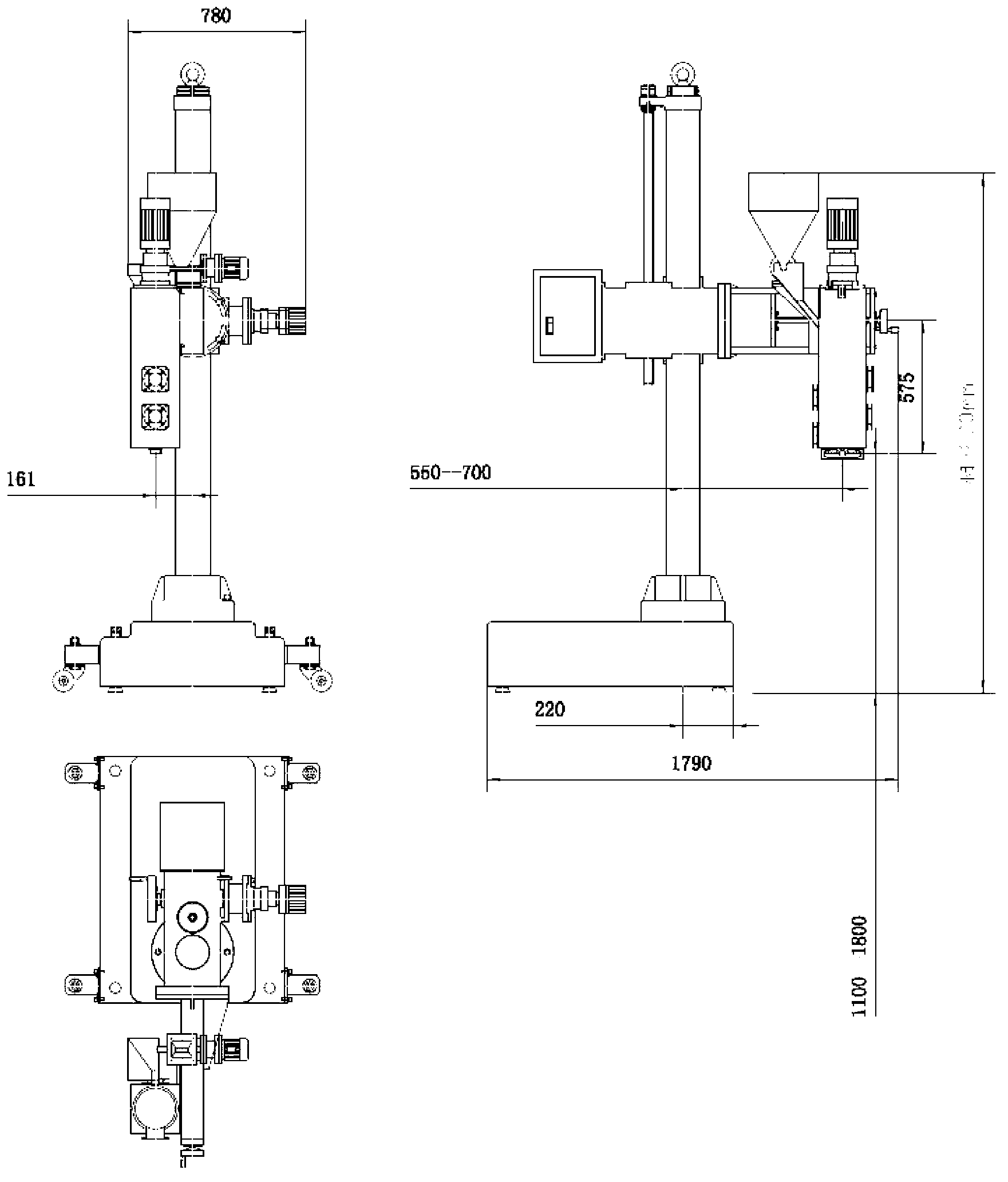

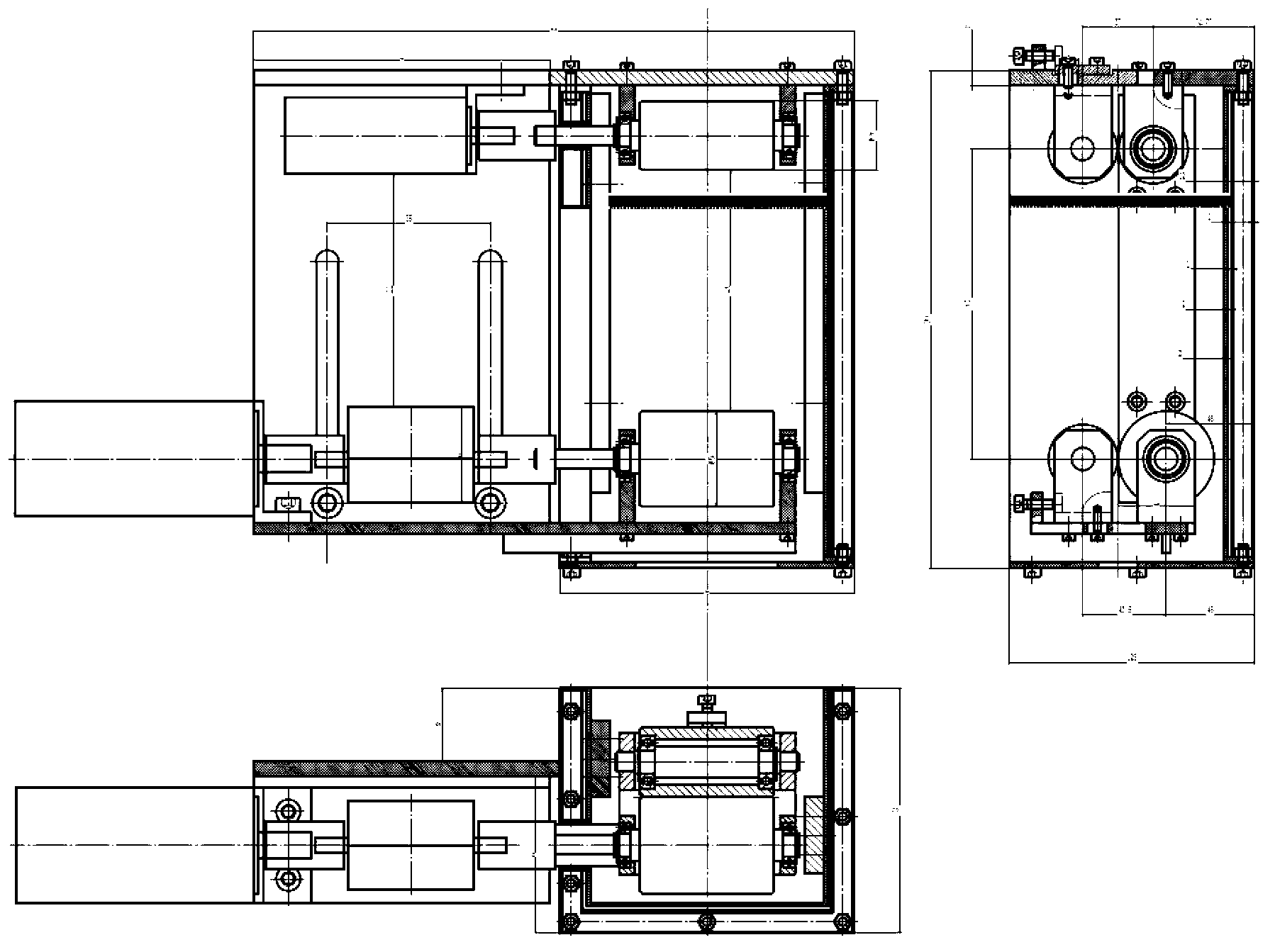

[0042] A kind of extruding stretching device combined with X-ray scattering, see appendix figure 1 , the high-precision extrusion control module 1 drives the screw to rotate, and extrudes the sample out of the die. The sample enters the No. 1 cavity 3 and is pulled or stretched by the No. 1 roller set 5 . Then the sample enters the No. 2 cavity 4 and is pulled or stretched by the No. 2 roller set 6 . The distance between the No. 1 and No. 2 roller sets can be adjusted by the screw mechanism 7 to ensure that the deformation rate and deformation amount of the sample between the two roller sets can be adjusted. The first cavity and the second cavity are controlled independently to meet the needs of simulating different processing temperature fields. The surface of the rollers of the No. 1 roller group and the No. 2 roller group is sprayed with polytetrafluoroethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com