Printed circuit board (PCB) assembling structure of alternating-current-direct-current electromagnet

A PCB board and assembly structure technology, applied in the direction of electromagnets, printed circuits connected with non-printed electrical components, etc., can solve problems such as lifting defective products, many assembly links, and glue leakage, so as to save glue injection time, Meet the requirements of use and reduce the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail with reference to the accompanying drawings, but the scope of protection of the present invention is not limited to the following embodiments, that is, all simple equivalent changes and modifications made based on the scope of the patent application of the present invention and the contents of the description shall still belong to the patent of the present invention. Within the scope of coverage.

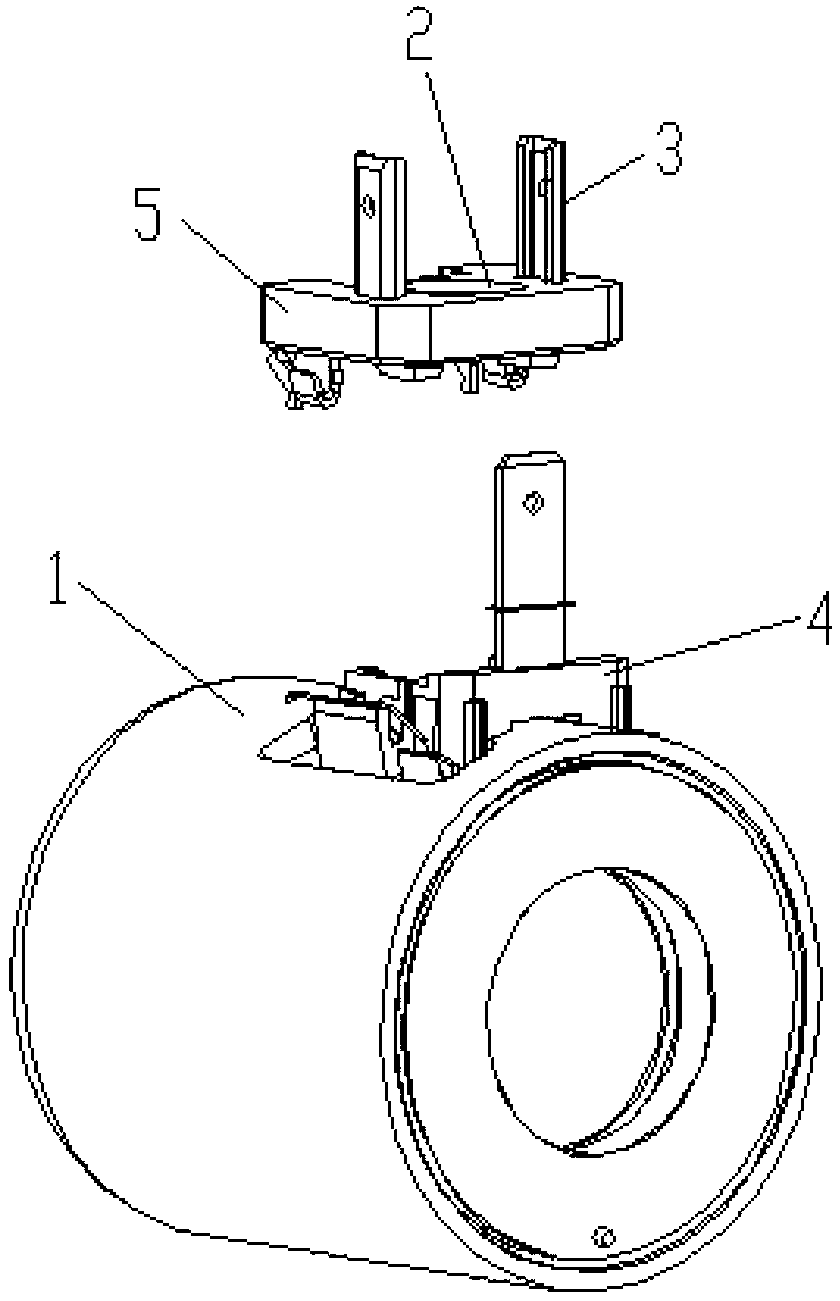

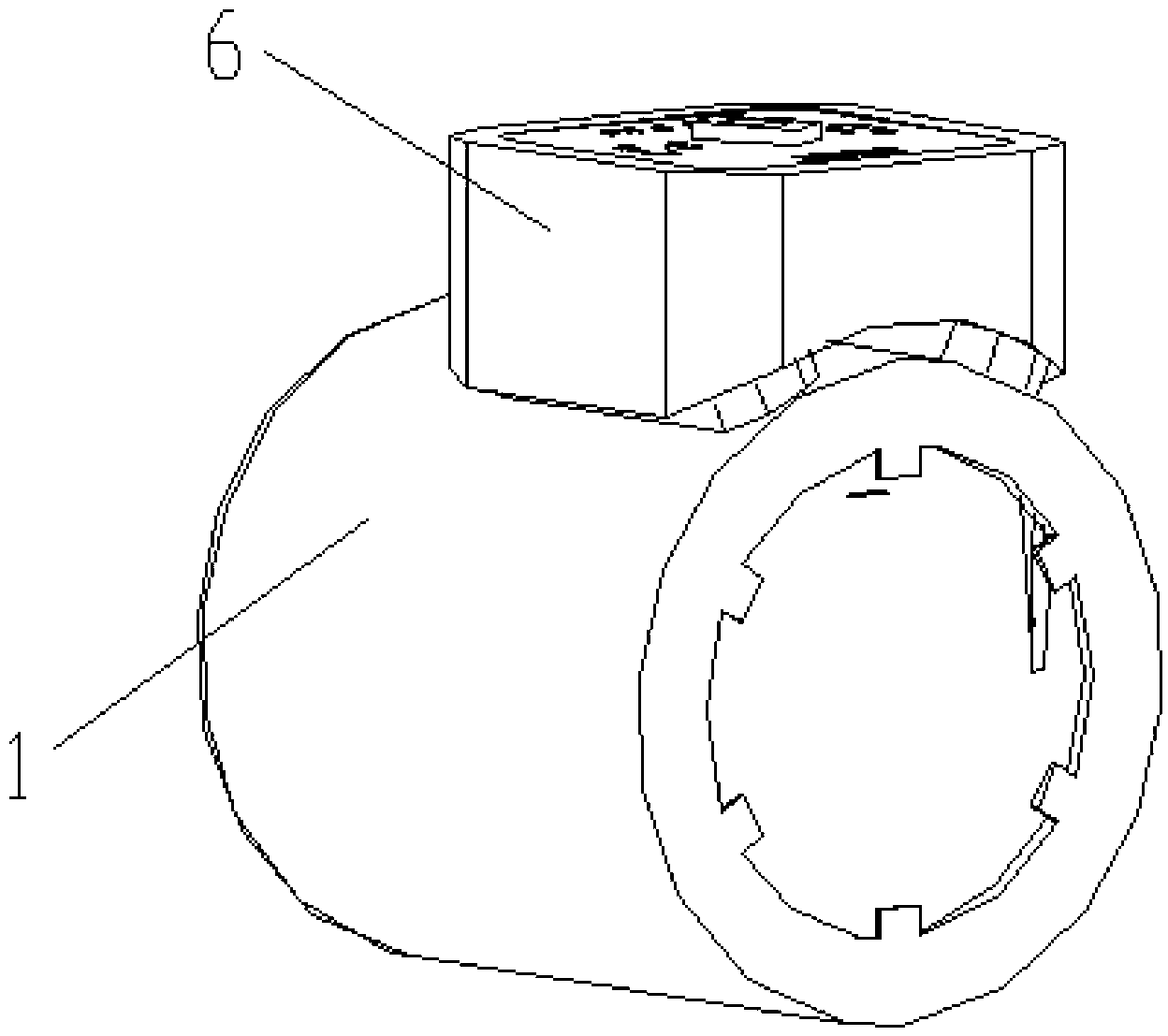

[0014] Such as figure 1 , 2 As shown, a PCB board assembly structure for AC and DC electromagnets includes a coil housing 1 for covering an electromagnet coil and a PCB board 2 integrated with a circuit that converts AC voltage to DC voltage. The PCB board is provided with electronics. Part 3 is also provided with a connecting board 4, one side of the connecting board is fixed to the coil housing; the PCB board and its electronic parts are integrally covered with a protective shell 5, which is fixed to the connecting On the other...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap