Five-hole power socket

A power socket and power supply technology, applied in circuits, electrical components, contact parts, etc., can solve the problems of poor heat dissipation effect, short service life, and many consumables of power socket sleeves, and achieve good heat dissipation effect and long service life. , the effect of less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

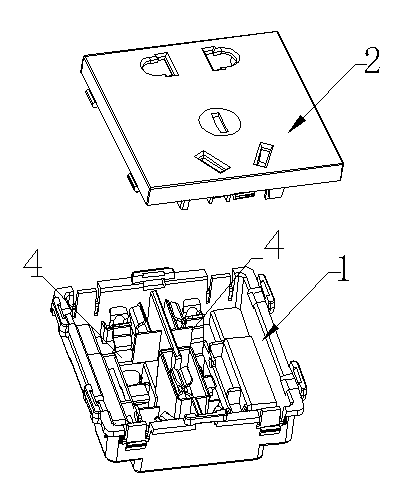

[0045] Such as figure 1 As shown, a five-hole power socket includes a base 1, a cover plate 2, and a power socket 4;

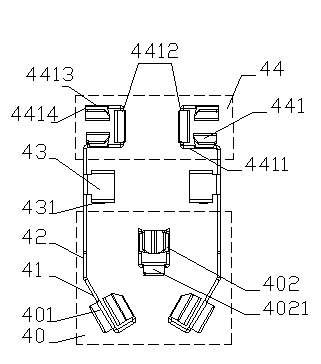

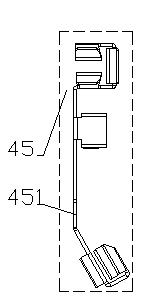

[0046] Such as figure 2 -3, the power socket 4 is composed of a three-hole socket 40 and a two-hole socket 44, a single-stage two-hole socket 441, a single-stage three-hole socket 401, and a power contact 43 form an independent single-stage The power supply socket 45; the ground wire socket 402 of the three-hole socket 40 is installed in the ground wire socket mounting seat 117 of the base 1, and the fixing method that the ground wire socket 402 often adopts is screw fixing and buckle fixing;

[0047] Such as figure 1 , Figure 4 As shown, the single-stage power socket 45 is symmetrically placed inside the groove 11 of the base; the above-mentioned base 1 cooperates with the cover 2 to form a rigid limiting system for fixing the power socket 4; The rigid limit system includes a line contact limit part and a surface contact limit part for limiting six degr...

Embodiment 2

[0053] Because the safety of the power socket is very important, on the basis of embodiment 1, embodiment 2 adds a safety door system. Such as Figure 7 As shown in —10, a safety door system 3 is provided at the two-hole socket 44 at the five-hole power socket; the safety door system 3 includes a compression spring 32 and a safety door sliding sleeve 31; one end of the compression spring 32 is installed on the safety door In the draw-in groove 311 of the sliding sleeve 31, the other end of the compression spring 32 is supported on the cover plate 2, and the safety door sliding sleeve 31 is installed in the guide box 22 of the cover plate 2 as a whole, and the outer wall of the safety door sliding sleeve 31 contacts the guide box 22. Inner wall; the safety door sliding sleeve 31 is provided with a guide groove 312, and the guide groove 312 is installed on the guide rib 12 of the base 1; the upper surface of the safety door sliding sleeve 31 is provided with a groove for prevent...

Embodiment 3

[0057] On the basis of Example 2, such as Figure 12 As shown, the line contact limiting part also includes two thimbles II 24 arranged on the cover plate 2 to push against the upper surface 451 of the single-stage power socket 45 near the three-hole socket 40 .

[0058] In the actual working process, the three-hole external power plug is inserted into the three-hole socket 40, and after use, the three-hole external power plug is manually pulled out. When pulling out the three-hole external power plug, a moment will be generated with the power contact 43 as the fulcrum and the single-stage three-hole socket 401 as the stress point. Since the formula of the torque is: M=F L (moment=forceⅹdistance); the upper surface 451 of the single-stage power socket 45 close to the three-hole socket 40 is supported by the two thimbles II 24 arranged on the cover plate 2 On, the distance from the force point to the fulcrum is shortened, thereby reducing the moment.

[0059] The technical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com