High-voltage pulse power supply for plasma sewage treatment system

A technology of sewage treatment system and high-voltage pulse power supply, which is applied in the field of high-voltage pulse power supply, can solve the problems of single step-up link, large energy consumption, large volume, etc., and achieve the effects of improving efficiency, power density, and switching frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

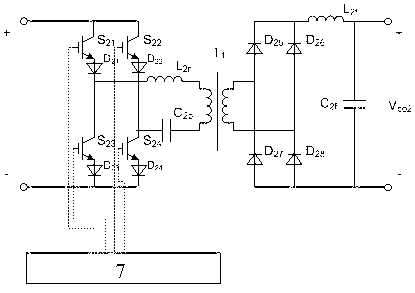

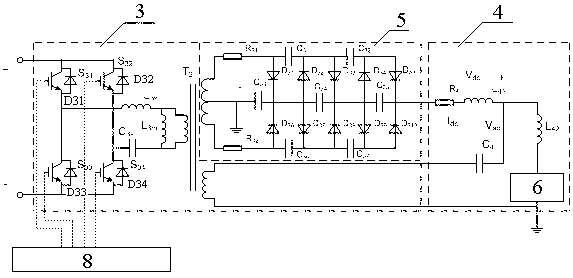

[0021] Example: Such as figure 1 As shown, a high-voltage pulse power supply for a plasma sewage treatment system includes a power frequency rectification filter circuit 1, a primary boost circuit 2, a secondary boost circuit 3 and a voltage coupling circuit 4,

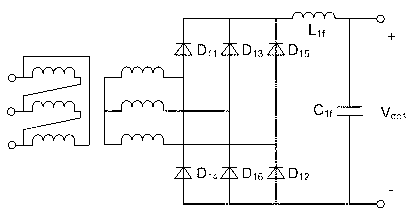

[0022] Specifically, as figure 2 As shown, the power frequency rectification filter circuit 1 includes 6 diodes D 11 ~D 16 The three-phase uncontrolled rectifier bridge and the filter inductor L 1f and filter capacitor C 1f The filter circuit composed of three-phase uncontrolled rectifier bridge output in series with the filter inductor L 1f After with the filter capacitor C 1f Parallel connection, input the three-phase voltage of the mains grid to the input end of the three-phase uncontrolled rectifier bridge, the three-phase uncontrolled rectifier bridge converts the three-phase voltage into DC voltage, and the filter circuit removes the interference signal by the filter capacitor C 1f Output DC voltage V a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com