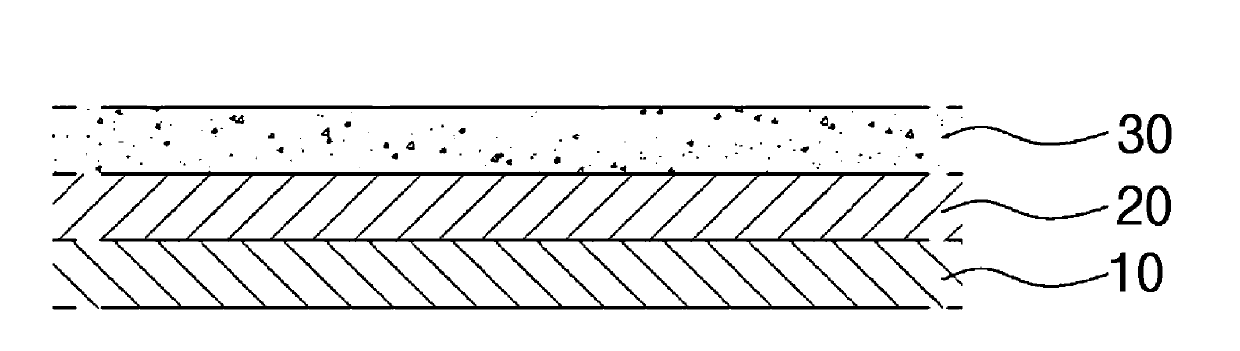

Electrode assembly for secondary battery and lithium secondary battery comprising same

A lithium secondary battery and electrode assembly technology, applied in battery electrodes, secondary batteries, secondary battery manufacturing, etc., can solve problems such as battery temperature rise, achieve the effects of ensuring safety performance, solving safety problems, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

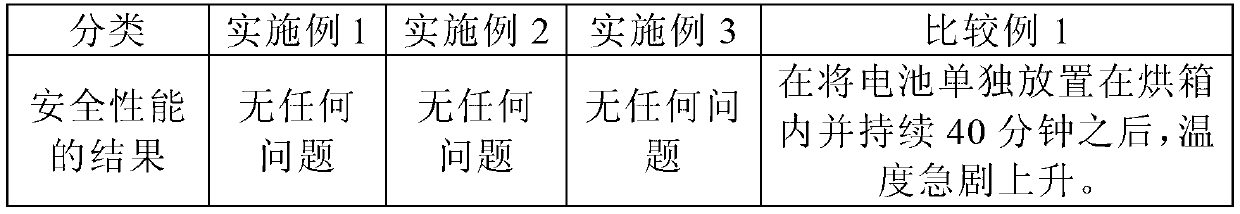

Embodiment 1

[0066] LiCoO as the positive electrode active material with a weight ratio of about 94:4:2 2 , polyvinylidene fluoride as a binder, and Ketjen black as a conductive material were mixed with N-methylpyrrolidone to prepare a cathode active material slurry. After coating the slurry on the aluminum foil, the slurry coated on the aluminum foil was dried to prepare a positive electrode coated part. The composition (PTC material) is coated on the positive electrode coating part to prepare the positive electrode, wherein based on 100 parts by weight of LiCoO 2 , The composition (PTC material) comprises 10 parts by weight of carbon black and 15 parts by weight of high-density polyethylene.

[0067] Amorphous carbon as a negative active material and polyvinylidene fluoride as a binder were mixed with N-methylpyrrolidone at a weight ratio of about 95:5 to prepare a negative active material slurry. After coating the slurry on the copper foil, the slurry coated on the copper foil was dri...

Embodiment 2

[0070] A pouch type lithium secondary battery was completed in the same manner as in Example 1 except that carbon fiber was used instead of carbon black.

Embodiment 3

[0072] In addition to using BaTiO 3 A pouch-type lithium secondary battery was completed in the same manner as in Example 1 except for the PTC material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com