How to make a sand mixer

A manufacturing method and technology for a sand mixer, which are applied in chemical instruments and methods, manufacturing tools, clay preparation devices, etc., can solve the problems of cumbersome manufacturing methods and high cost, and achieve simple and clear manufacturing steps, low cost, and excellent wear-resisting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

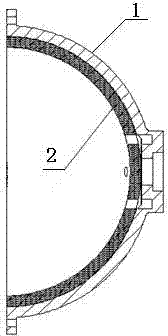

[0022] Such as figure 1 As shown, a sand mixer includes a tank body 1, the inner wall of the tank body 1 is provided with a wear-resistant layer 2, and the wear-resistant layer 2 is formed by mixing resin, curing agent and sand and solidifying on the inner wall of the tank body.

[0023] The thickness of the wear-resistant layer 2 is 8mm--15mm.

Embodiment 2

[0025] The manufacture method of the sand mixer in the present invention, (1) grinding of the inner wall of the sand mixer, utilizes emery cloth to polish the rust on the inner wall of the sand mixer;

[0026] (2) will take respectively by weight, particle diameter is 100 parts of 40 mesh sands, XLI318 type resin is 0.8 part, and GP-202GTN type curing agent is 1 part, mixes and mixes thoroughly and becomes coating; XLI318 resin is marketed The resin produced by Suzhou Xingye Material Technology Co., Ltd. is sold without heating. The GP-202GTN curing agent is the curing agent produced by Jinan Shengquan Group Co., Ltd. sold on the market.

[0027] (3) Put the paint formed in the above step (2) into the sand mixer and rotate the sand mixer. The paint will be automatically coated on the inner wall of the sand mixer with the rotation of the sand mixer until it solidifies.

[0028] The method has simple and clear steps, convenient operation, cheap materials, and can be used everywh...

Embodiment 3

[0030] The manufacture method of the sand mixer in the present invention, (1) grinding of the inner wall of the sand mixer, utilizes emery cloth to polish the rust on the inner wall of the sand mixer;

[0031] (2) will get respectively by weight, particle diameter is 100 parts of 50 mesh sands, 0.9 part of XLI318 type resin, and 1 part of GP-202GTN type curing agent is mixed and mixed into coating;

[0032] (3) Put the paint formed in the above step (2) into the sand mixer and rotate the sand mixer. The paint will be automatically coated on the inner wall of the sand mixer with the rotation of the sand mixer until it solidifies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com