New green synthesis process of dimethoxyethane

A technology for ethylene glycol dimethyl ether and green synthesis, which is used in ether preparation, alkylene oxide preparation of ether, organic chemistry, etc., and can solve problems such as difficulty in separation and purification, environmental pollution, and complex products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

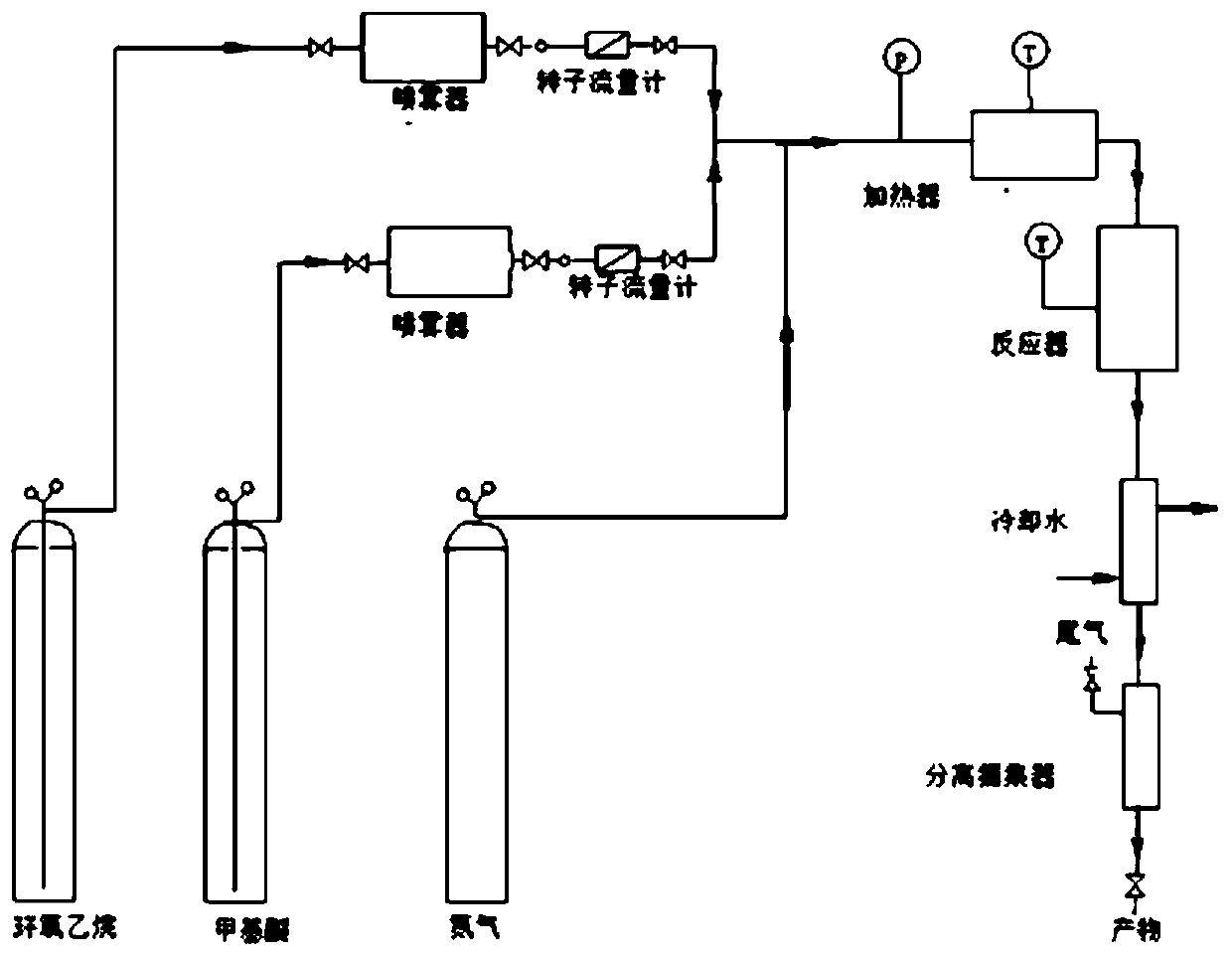

[0017] A new green synthesis process of ethylene glycol dimethyl ether. It includes ethylene oxide storage tanks, dimethyl ether storage tanks, sprayers, rotameters, nitrogen cylinders, heaters, reactors, coolers, separation traps, and the equipment is connected in sequence through pipelines.

[0018] Among them, the high-temperature reactor is a tubular fixed-bed reactor; ethylene oxide and dimethyl ether are injected into the system through high-pressure nitrogen, and are vaporized by the sprayer respectively, and then further gasified and mixed by the heater; the high-temperature product is cooled by the condenser captured after processing.

[0019] The specific process of the process is as follows figure 1 :

[0020] Replace the 0.5 L stainless steel autoclave with nitrogen to replace the air in the autoclave; use nitrogen pressure to feed the metered liquid catalyst, nitrogen pressure to feed the metered dimethyl ether, turn on the stirring, turn on the cooling water, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com