Membrane stripping apparatus

A film stripping equipment and film stripping technology, applied in electronic equipment, lamination, application, etc., can solve the problems of limited application range, residual glue pollution, high cost, etc., and achieve the effect of reducing residual glue pollution and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

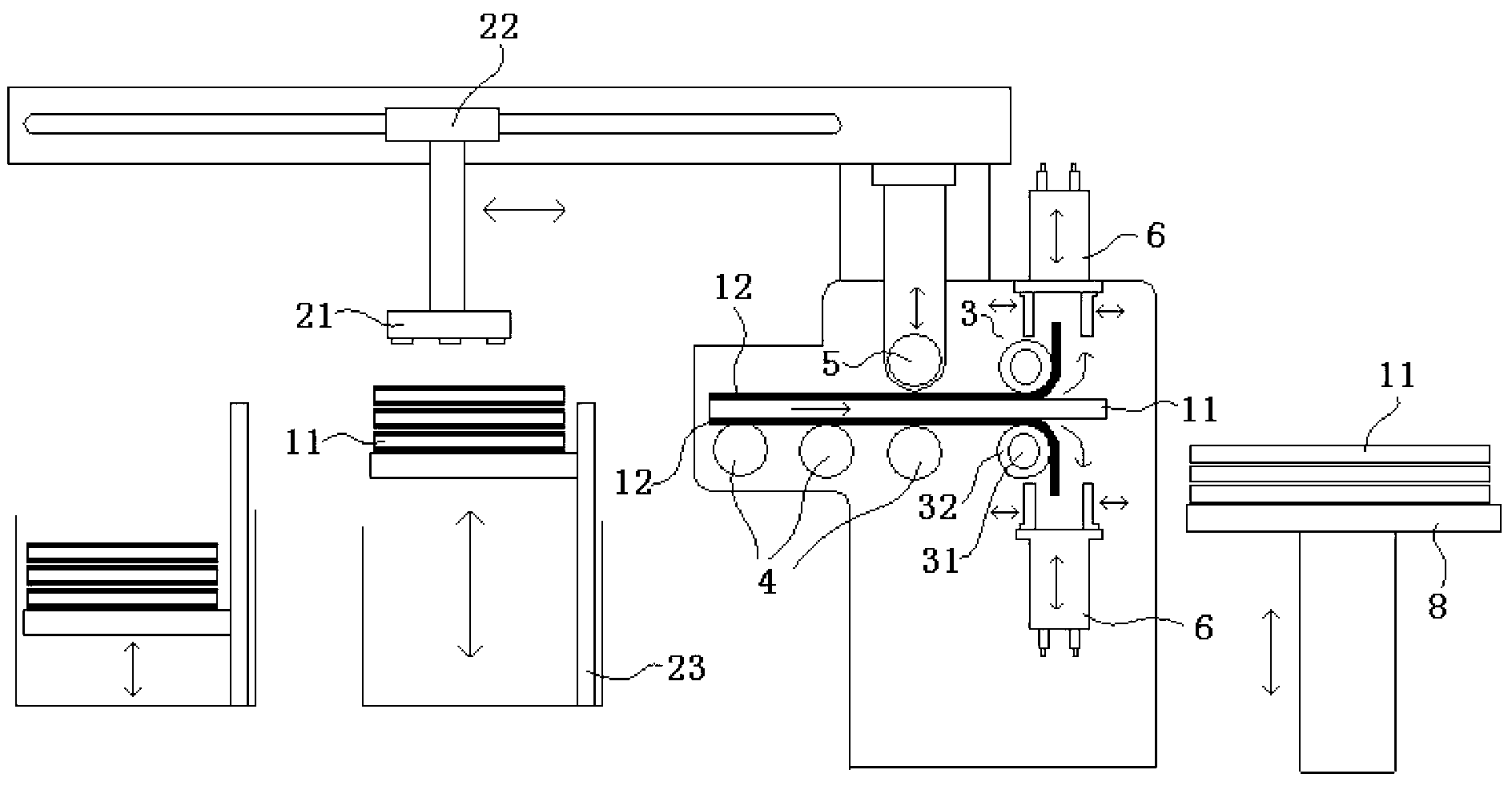

[0031] This embodiment provides a stripping device, such as figure 2 As shown, it includes two film peeling rollers 3, feeding mechanism, driving mechanism (not shown in the figure).

[0032] Wherein, the feeding mechanism is used to send the material 11 to be stripped between the two stripping rollers 3 (i.e. its feeding side, figure 2 middle left) for peeling.

[0033] Preferably, the feeding mechanism includes a feeding roller 4 or a feeding belt for supporting the material 11 to be peeled; the material 11 to be peeled can be moved by the rotation of the feeding roller 4 or the feeding belt.

[0034] This roller or belt feeding mechanism has the advantages of simple structure, low cost and reliable operation, and is suitable for both hard and soft materials 11 .

[0035] More preferably, the stripping device also includes a positioning mechanism located at the feeding side of the stripping roller 3, and the positioning mechanism includes a positioning roller 5 that is s...

Embodiment 2

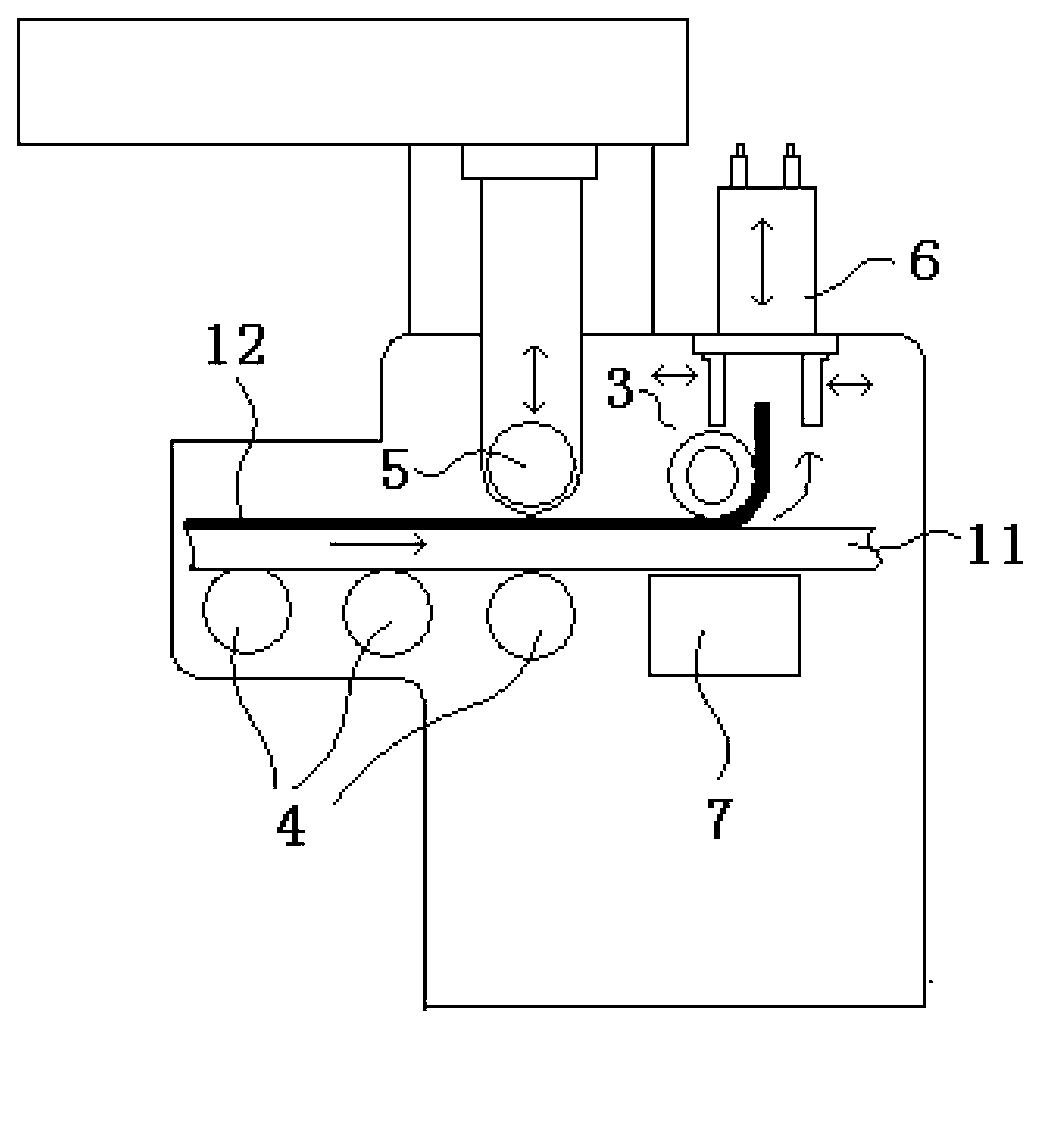

[0062] This embodiment provides a stripping device, which has a similar structure to the stripping device in Embodiment 1, the difference is that:

[0063] Such as image 3 As shown, in the film stripping equipment of this embodiment, opposite to the film stripping roller 3 is an adsorption mechanism 7 for absorbing the material 11 being stripped.

[0064] Obviously, some materials 11 have only one side of the film layer 12 that needs to be peeled off, so only one peeling roller 3 can be used to peel off the film, and because the peeling operation has only one active force on the material 11 in this case. One direction, so it is necessary to set the adsorption mechanism 7 opposite to the peeling roller 3 to prevent the material 11 from being deformed or taken away with the film layer 12 (especially for soft film materials).

[0065] Of course, there are various ways to realize that the peeling roller 3 and the adsorption mechanism 7 are relatively arranged; for example, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com