Penetration type transparent concrete protection paint and preparation method thereof

A technology for protective coatings and concrete, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unreasonable structural design of concrete structures, failure to achieve expected life, deterioration, etc., and achieve considerable bond strength and increase compactness. , the effect of improving frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

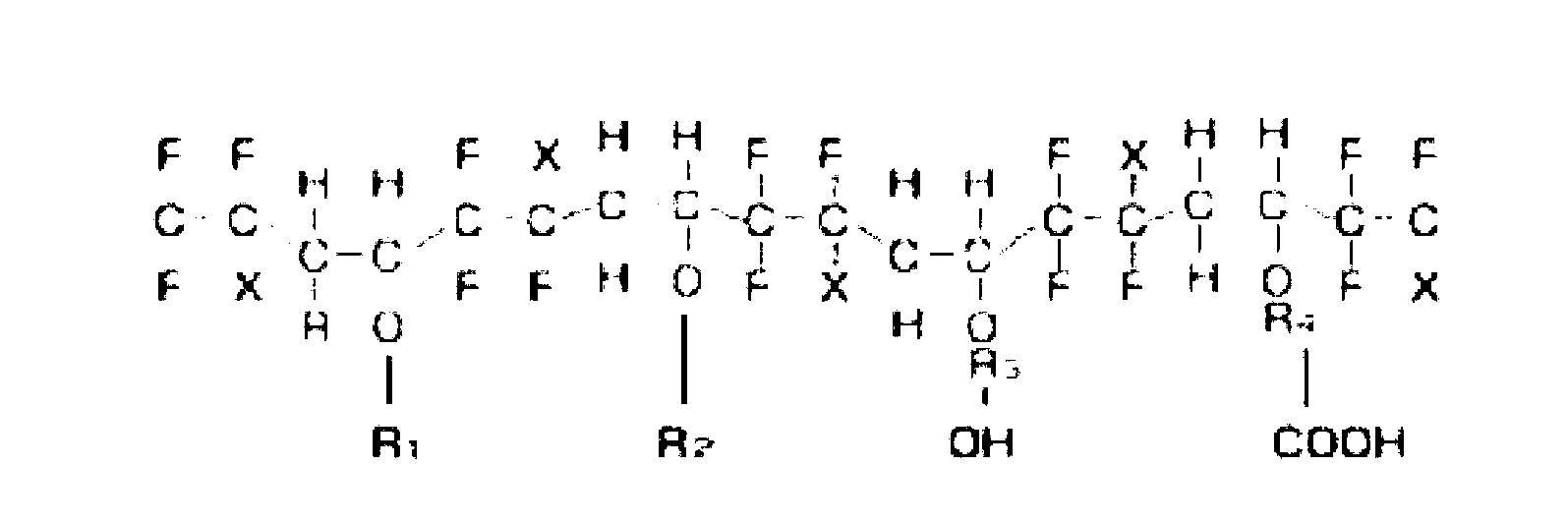

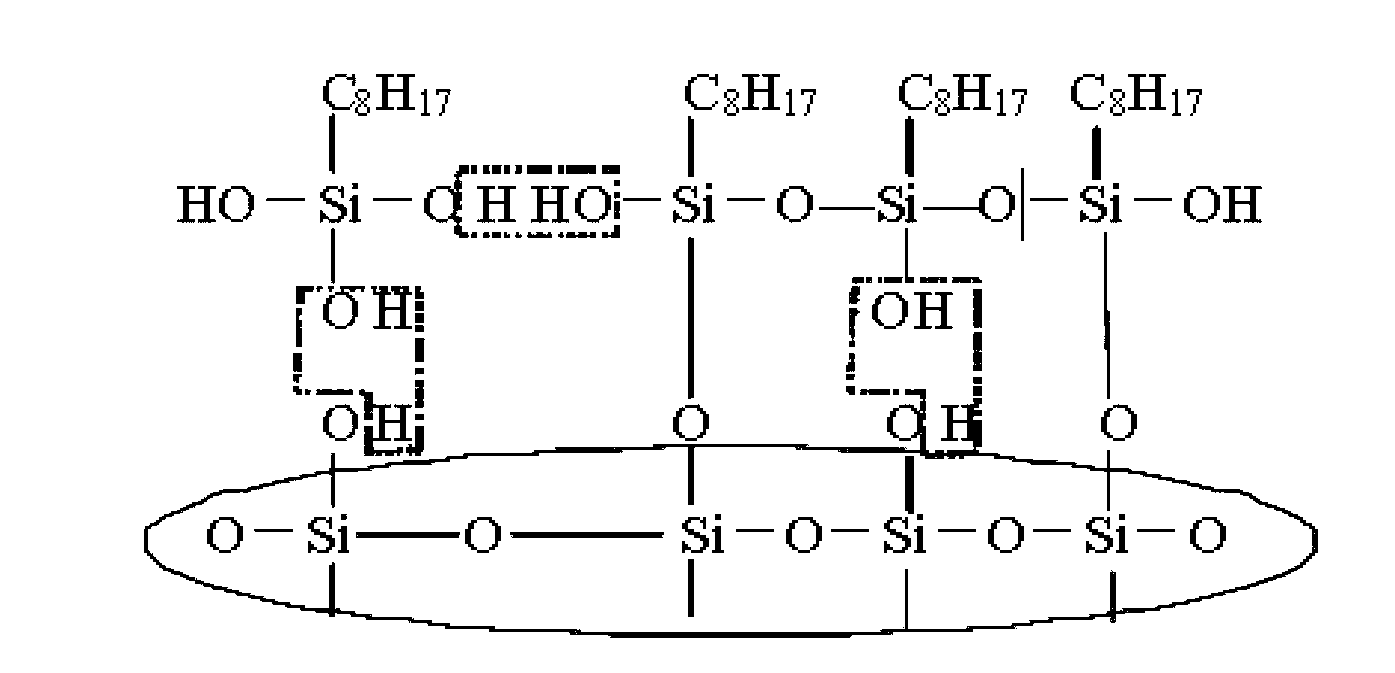

Method used

Image

Examples

Embodiment 1-2

[0039] Prepare a high-permeability weather-resistant transparent concrete protective coating, the formula is as follows (by weight):

[0040] Table 1 Embodiment 1-2 formula

[0041] Example

1

2

FEVE / part

45

45

Trimeric isocyanate / part

7

20

Butyl acetate / part

35

35

Methyldimethoxysilane / part

9

9

[0042] The preparation method process is:

[0043] (1) Weigh each component material according to the proportion;

[0044] (2) First dilute FEVE with butyl acetate;

[0045] (3) Add isocyanurate and stir for 20 minutes;

[0046] (4) Add methyldimethoxysilane and stir for 10 minutes to mix evenly to obtain the concrete protective coating.

[0047] The prepared protective coating was coated on C20 concrete, and the C20 concrete sample not coated with protective coating was used as a blank control. The performance test results were as follows:

[0048] Table 2 embodiment 1-2 protection performance

...

Embodiment 3

[0053] Prepare a high-permeability weather-resistant transparent concrete protective coating, the formula is as follows (by weight):

[0054] PVDF 50

[0055] Melamine 7

[0056] Xylene 40

[0057] Isobutylsilane 10

[0058] The preparation method process is:

[0059] (1) Weigh each component material according to the proportion;

[0060] (2) First dilute PVDF with xylene;

[0061] (3) Add melamine and stir for 20 minutes;

[0062] (4) Add isobutylsilane and stir for 10 minutes to mix evenly to obtain the concrete protective coating.

[0063] After the coating treatment, the properties of concrete (C50) are as follows:

[0064] Table 3 embodiment 3 protection performance

[0065] Example

Water absorption / mm·min -1 / 2

Penetration depth / mm

3

0.0017

0.86

Blank control (C50)

0.0073

/

[0066] The obtained paint is transparent and viscous liquid in the container, and because of its high permeability, after the paint is h...

Embodiment 4

[0069] Prepare a high-permeability weather-resistant transparent concrete protective coating, the formula is as follows (by weight):

[0070] FEVE 40

[0071] Melamine 7

[0072] Butyl acetate 30

[0073] Isobutylsilane 4

[0074] Methyldimethoxysilane 4

[0075] The preparation method process is:

[0076] (1) Weigh each component material according to the proportion;

[0077] (2) First dilute FEVE with butyl acetate;

[0078] (3) Add melamine and stir for 20 minutes;

[0079] (4) Add isobutylsilane and methyldimethoxysilane, stir for 15 minutes and mix evenly to obtain the concrete protective coating.

[0080] After being treated with this coating, the properties of concrete (C20) are as follows:

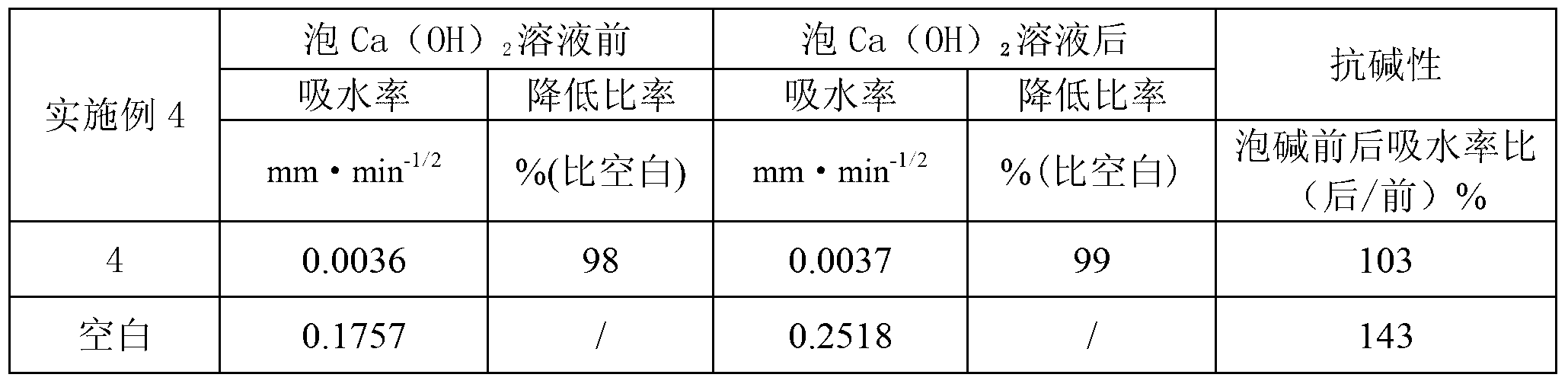

[0081] Table 4 embodiment 4 paint protection performance

[0082]

[0083] Carry out experiment according to the proportioning of embodiment 4 and know, the sample water absorption rate of the blank group before the natron is far greater than embodiment 4, illustrate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com