Corrosion inhibitor used in carbon steel corrosion in ammonia-method desulphurization ammonium sulfate preparation system

A technology of ammonia desulfurization and corrosion inhibitor, which is applied in the chemical field to achieve the effect of good corrosion inhibition performance, small dosage and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

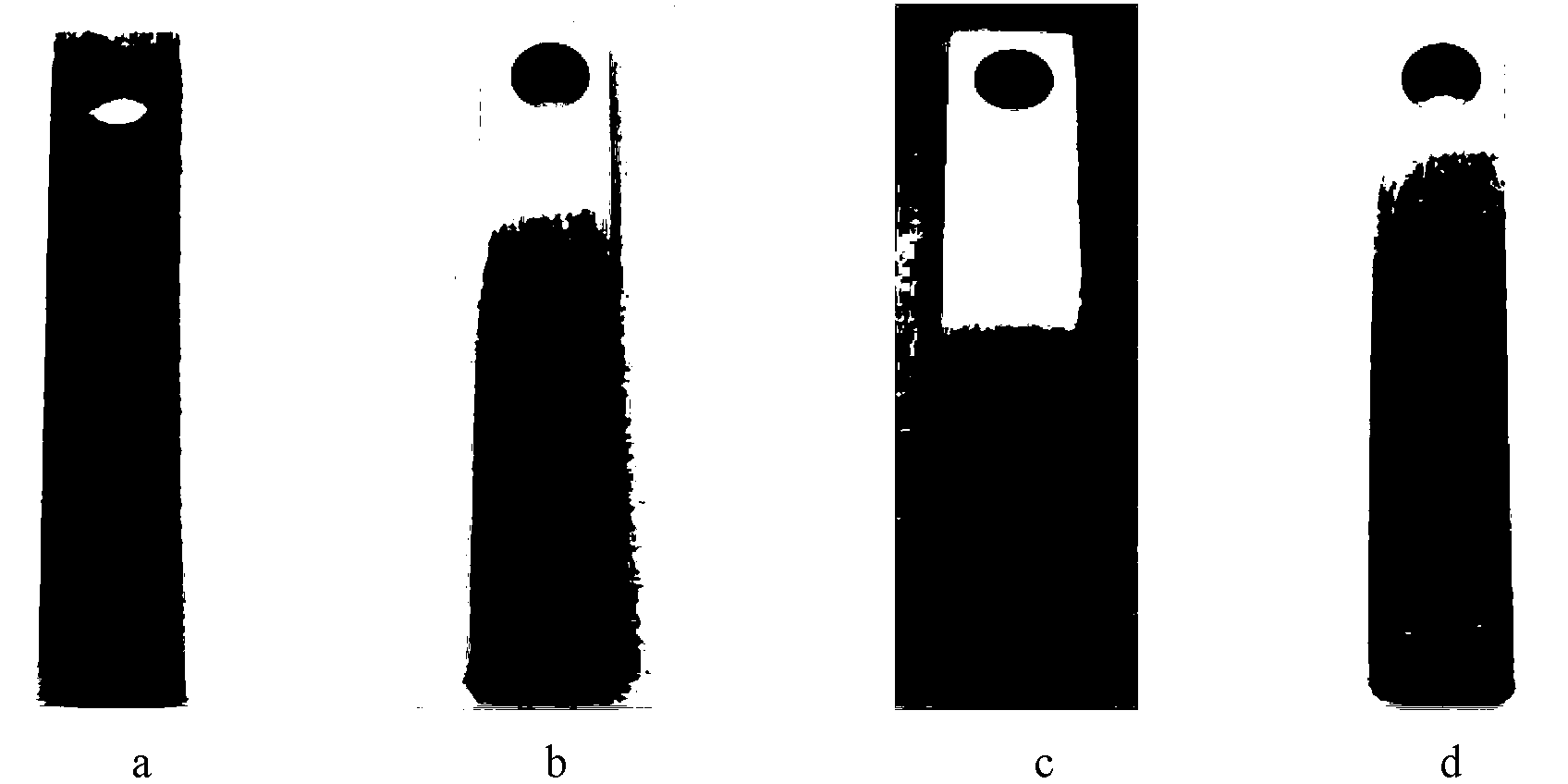

Image

Examples

Embodiment 1-9

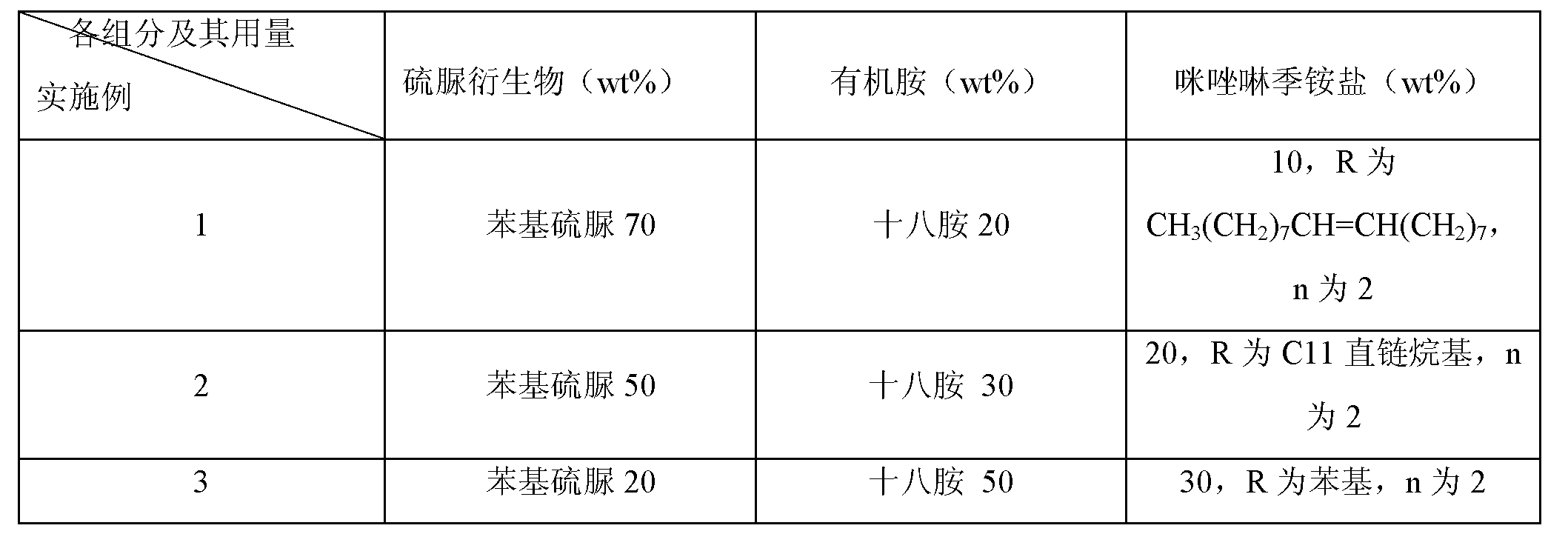

[0028] The corrosion inhibitor is composed of thiourea derivatives, organic amines and imidazoline quaternary ammonium salts. The selection and content of the components in each embodiment are shown in Table 1.

[0029] Table 1 The amount of components in each embodiment

[0030]

[0031]

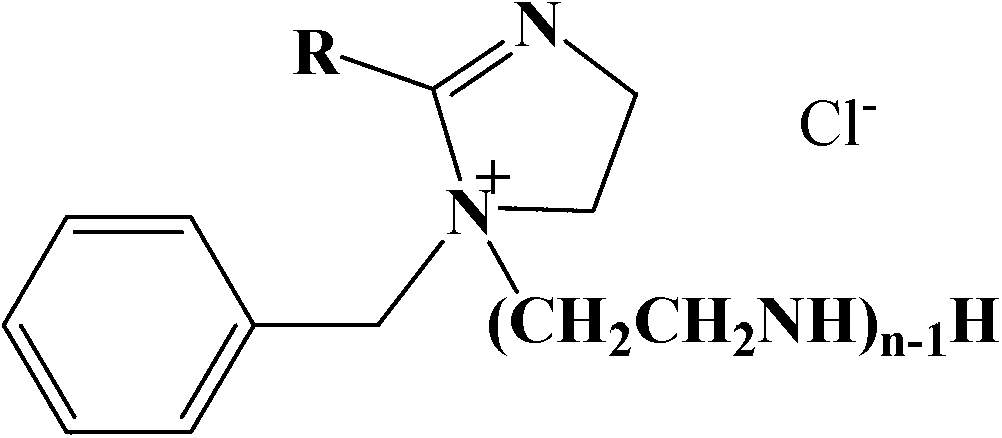

[0032] The imidazoline quaternary ammonium salt is It is a combination of organic carboxylic acid RCOOH and polyvinyl polyamine NH 2 CH 2 CH 2 NH(CH 2 CH 2 NH) n-1 H is added to the reaction vessel at a molar ratio of 1:1, where R and n are selected as described in the table above, and then at a molar ratio of xylene: organic carboxylic acid = 150:1, xylene is added as a water-carrying agent, 150 Reacted at ℃ for 2h, then heated to 200℃, after 2h of reaction, cooled to 50℃, and then added dropwise benzyl chloride, the benzyl chloride and polyvinyl polyamine NH 2 CH 2 CH 2 NH(CH 2 CH 2 NH) n-1 The molar ratio of H is 1:1, the temperature is controlled to 100°C, and the reaction time is 1 to 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com