Flow pattern controllable type bubble atomizing nozzle

A technology of atomizing nozzles and nozzles, which is applied in fuel injection devices, engine components, machines/engines, etc., can solve the problems of bubble atomizing nozzles that cannot control nozzle flow patterns, etc., to increase the frequency of bubble detachment and improve stability , the effect of reducing the size of the bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

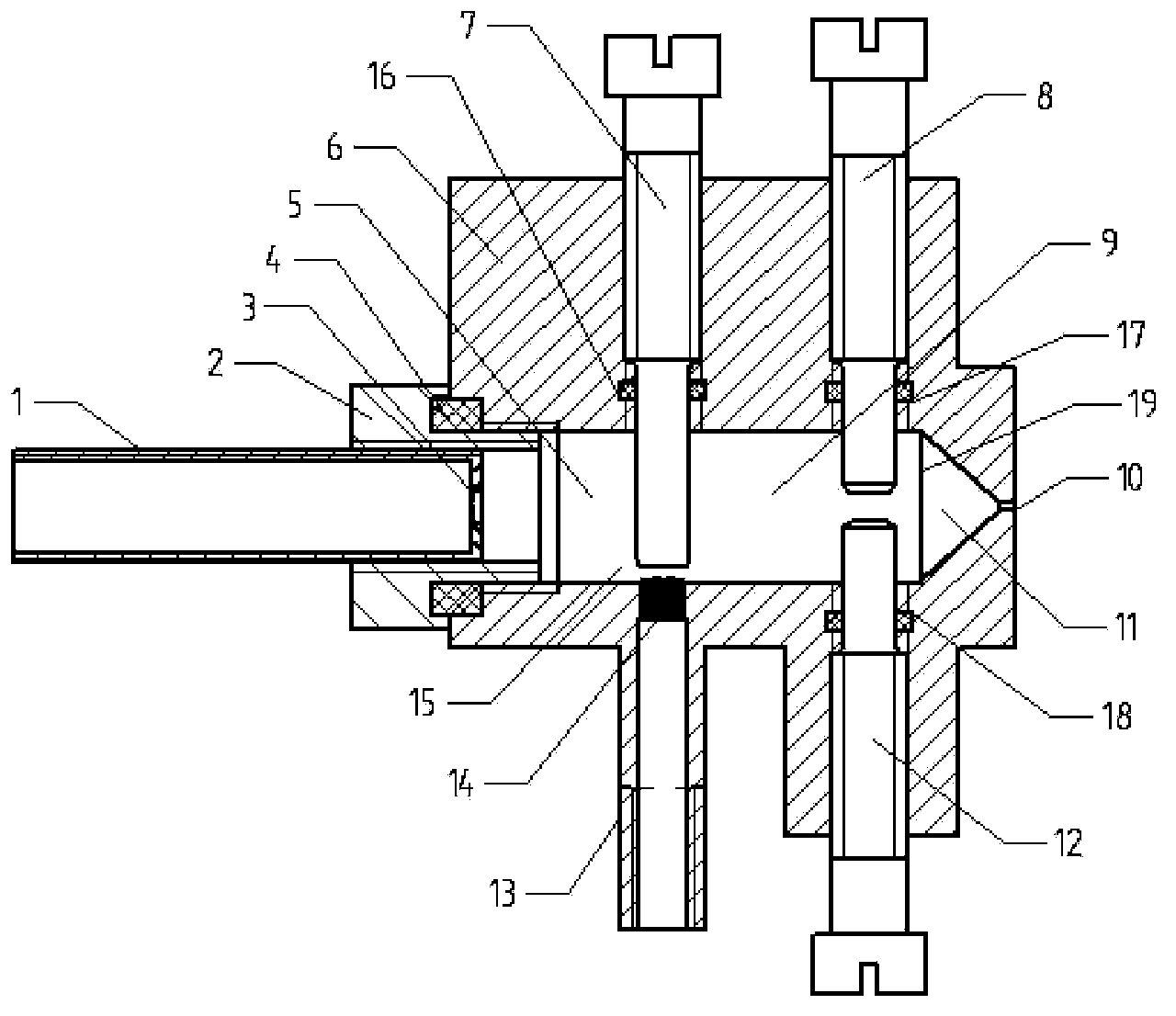

[0026] A controllable flow-type bubble atomizing nozzle, such as figure 1 As shown, the bubble atomizing nozzle includes: liquid filling pipe 1, liquid filling pipe sleeve 2, sealing gasket 4, nozzle 6, hydraulic diameter regulator 7 at the place where bubbles are generated, first and second geometric regulators near the nozzle hole 8, 12, inflatable tube 13, bubble generator 14, first, second and third O-rings 16, 17 and 18.

[0027] The liquid-filling pipe 1 and the liquid-filling pipe sleeve 2 are threadedly connected, and the liquid-filling pipe sleeve 2 is threadedly connected with the nozzle and sealed by a sealing gasket 4 ; the bubble generator 14 is installed on the nozzle 6 .

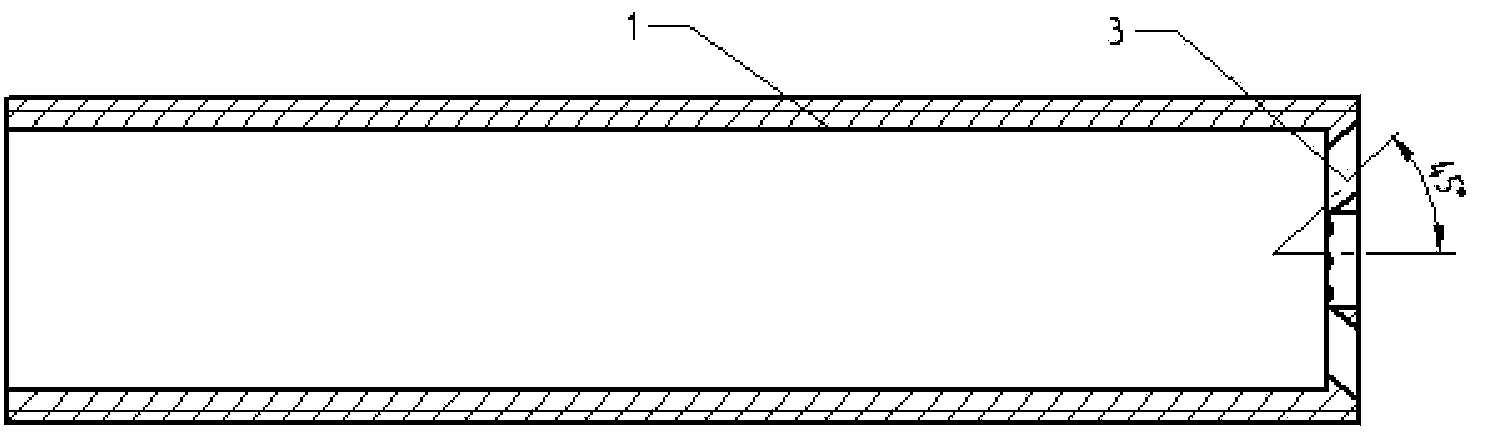

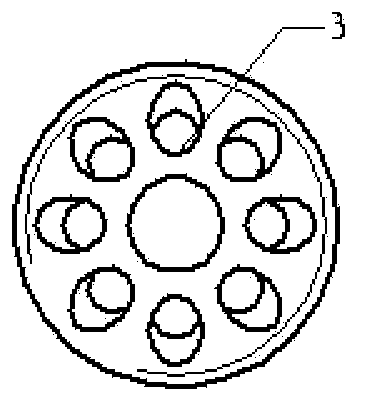

[0028] Different direction liquid filling holes 3 are arranged on the end surface of the end of the liquid filling pipe 1 .

[0029] Described inflation pipe 13 and bubble generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com